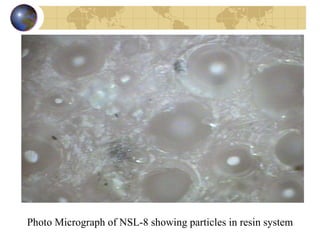

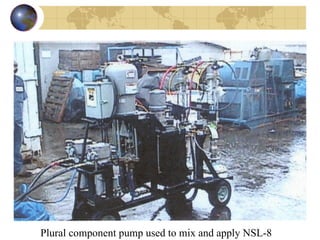

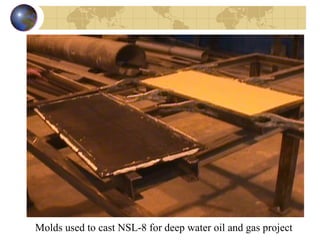

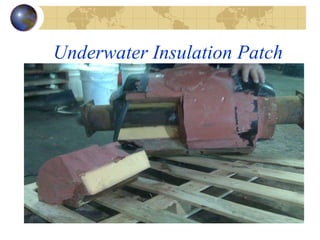

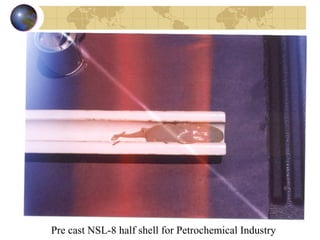

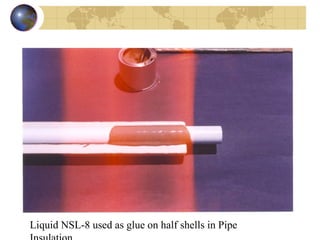

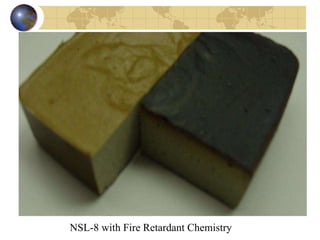

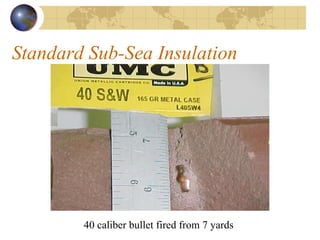

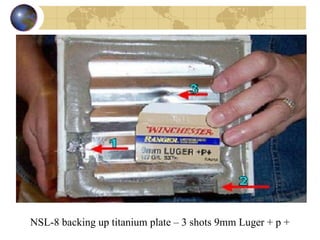

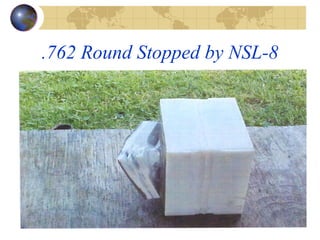

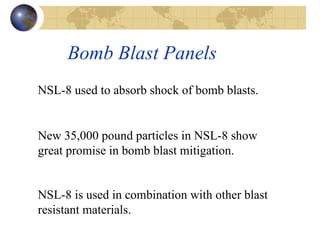

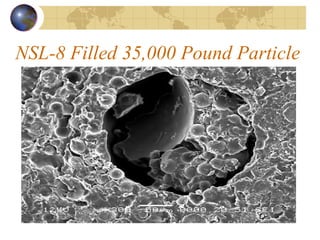

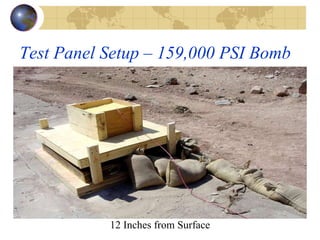

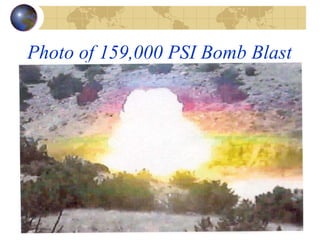

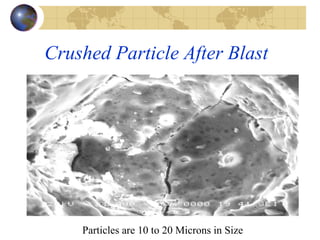

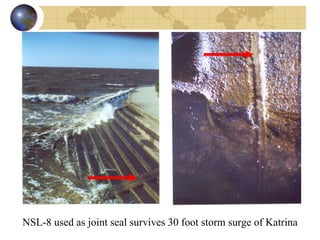

NSL-8 is a flexible epoxy resin material made of solvent-free epoxy, amine curing agent, and various filler materials. It has properties making it suitable for thermal insulation and vibration damping applications in harsh environments like the oil and gas industry offshore. Some potential uses discussed include underwater insulation patches, buoyancy materials, pipeline coatings, and ballistic barriers. The document provides examples of NSL-8 stopping bullets and absorbing the impact of high explosive bomb blasts, demonstrating its insulating and protective capabilities.