SW_LIFT.pdf

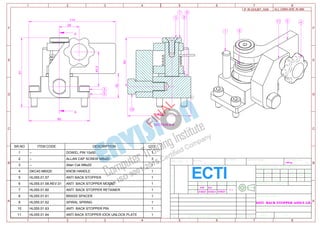

- 1. A 1 C B 2 3 4 E D F 1 2 3 4 5 6 7 8 A B C IF IN DOUBT, ASK ALL DIMN.ARE IN MM 5 6 7 D E 8 F ANTI BACK STOPPER ASSLY.LH. 1.66 kg - - 31/08/21 31/08/21 31/08/21 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A3 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg - R.K ECTI A.M - SR.NO ITEM CODE DESCRIPTION QTY. 1 -- DOWEL PIN 10x50. 1 2 -- ALLAN CAP SCREW M8x20 3 3 -- Allan Csk M8x20 1 4 DKC40 M8X20 KNOB HANDLE 1 5 HL055.01.57 ANTI BACK STOPPER 1 6 HL055.01.58.REV.01 ANTI BACK STOPPER MOUNT 1 7 HL055.01.60 ANTI BACK STOPPER RETAINER 1 8 HL055.01.61 BRASS SPACER 1 9 HL055.01.62 SPIRAL SPRING 1 10 HL055.01.63 ANTI BACK STOPPER PIN 1 11 HL055.01.64 ANTI BACK STOPPER IOCK UNLOCK PLATE 1 80 A A SECTION A-A 6 3 114 32 91 1 9 10 2 5 4 7 8 6 64 83 26 45.5 11 F I N A L

- 2. A 1 C B 2 3 4 E D F 1 2 3 4 5 6 7 8 A B C IF IN DOUBT, ASK ALL DIMN.ARE IN MM 5 6 7 D E 8 F ANTI BACK STOPPER ASSLY.RH.. 0.00 kg - - 31/09/21 31/09/21 31/09/21 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A3 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg - R.K A.M ECTI SR.NO ITEM CODE DESCRIPTION QTY. 1 -- ALLAN CAP SCREW M8x20 8 2 -- Allan Csk M8x20 1 3 -- DOWEL PIN 10x50. 1 4 HL055.01.57 ANTI BACK STOPPER 1 5 HL055.01.58 ANTI BACK STOPPER MOUNT 1 6 HL055.01.59.REV.01 ANTI BACK STOPPER IOCK UNLOCK PLATE 1 7 HL055.01.60 ANTI BACK STOPPER RETAINER 1 8 HL055.01.61 BRASS SPACER 1 9 HL055.01.62 SPIRAL SPRING 1 3 2 4 9 5 6 80 99 A A SECTION A-A 7 6 8 72 79 72 62 1 F I N A L

- 3. A 1 B C D 2 3 4 5 E F G H I 1 2 3 4 5 6 7 8 9 10 11 12 A B C D 6 7 8 9 10 E F G IF IN DOUBT, ASK ALL DIMN.ARE IN MM 11 12 H I SW 055.01 SW LIFT-1 0.00 kg 02.11.21 02.11.21 02.11.21 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A1 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg AM RK ECTI SR. NO. ITEM CODE ITEM DESCRIPTION QTY 1 PARALLEL KEY-8x7x124L 2 2 6208-ZZ 4 3 PARALLEL KEY-8x7x124L 1 4 HYDRAULIC CYLINDER BORE-63x STROKE =195, PIN CENTRE TO CENTRE 475MM 2 5 - SENSOR LIMIT SWITCH NG1-VS-510L24 WITH LED 24 V DC. 1 6 - SENSOR LIMIT SWITCH NG1-VS-510L24 WITH LED 24 V DC. 1 7 -- ALLEN CAP SCREW M8 x 45Lg. 18 8 -- ALLAN CAP SCREW M6x16 8 9 -- ALLAN CAP SCREW M6x10L 8 10 -- Allan Csk M8x20 48 11 -- ALLAN CAP SCREW M8x20 28 12 -- ALLAN CAP SCREW M5x10 4 13 -- ALLAN CAP SCREW M6x30 2 14 -- ALLN CSK M8x16( S .S ) 12 15 -- ALLAN CAP SCREW M10x20 32 16 -- BEARING SKF-6206 ZZ 4 17 -- ALLAN CAP SCREW M5x40 8 18 -- BEARING DEEP GROOVE 6006ZZ 4 19 -- LOCK NUT M8 4 20 -- HEX BOLT M8x35 4 21 -- ALLEN CAP SCREW M10x30Lg. 20 22 -- CIRCLIP INTERNAL B-55 4 23 -- PLAIN BEARING BUSH 4 24 -- INT. CIRCLIP B-47 4 25 -- ALLAN C'SUNK SCREW M6x16L 62 26 -- ALLAN C'SUNK SCREW M6x16L 4 27 -- BALL BEARING 6005 4 28 -- ALLEN C'SUNK SCREW M6x10Lg. 28 29 -- ALLEN CAP SCREW M8x35 2 30 1/2"-52 PITCHES - 660.4 LONG + 1 LINK DUPLEX CHAIN-1/2" 1 31 HL055.01.-34.REV 01 POWER PACK MOUNT 4 32 HL055.01.01 BOTTOM FRAME 1 33 HL055.01.02 BOTTOM RAIL 2 34 HL055.01.03 SCISSOR PLATE-1 2 35 HL055.01.04 SCISSOR PLATE-2 2 36 HL055.01.05 TOP FRAME 1 37 HL055.01.06 ROLLER 4 38 HL055.01.07 ROLLER PIN 4 39 HL055.01.08 ROLLER RETAINER 4 40 HL055.01.09 FIX PIVOT PIN 4 41 HL055.01.10 CENTER PIN 2 42 HL055.01.11 CENTER PIVOT RETAINER 6 43 HL055.01.12 BEARING BOSS 4 44 HL055.01.13 WHEEL BRACKET REAR SIDE 2 45 HL055.01.14 WHEEL PIN 2 46 HL055.01.15 DRIVEN WHEEL 2 47 HL055.01.16 WHEEL RETAINER 2 48 HL055.01.17 WHEEL SPACER 2 49 HL055.01.18 RAIL-1 2 50 HL055.01.19 RAIL ON TABLE 2 51 HL055.01.20 WHEEL SHAFT 1 52 HL055.01.21 SPROCKET REWORK 2 53 HL055.01.22 FRONT PIVOT BRACKET 1 54 HL055.01.23 REAR PIVOT BRACKET 1 55 HL055.01.24 STOPPER 3 56 HL055.01.25 STOPPER PAD 4 57 HL055.01.26 WHEEL STOPPER 6 58 HL055.01.27 CENTER PIVOT SPACER 2 59 HL055.01.28 TOP RAIL 2 60 HL055.01.29 REAR PIVOT LOCATOR 2 61 HL055.01.30 CYLINDER TOP PIN 4 62 HL055.01.31 CYLINDER TOP SPACER 8 63 HL055.01.32 DRIVE MOUNTING PLATE 1 64 HL055.01.33 BRACKET 1 65 HL055.01.35 DRIVING WHEEL 2 66 HL055.01.36 ROLLER RETAINER-2 4 67 HL055.01.37 TOP PLATE -1 1 68 HL055.01.38 SPROCKET RETAINER 1 69 HL055.01.39 GEARBOX-SHAFT 1 70 HL055.01.40 G.B. SHAFT RETAINER 3 71 HL055.01.41 WHEEL BRACKET FRONT SIDE 2 72 HL055.01.42 FRONT WHEEL SPACER 4 73 HL055.01.43 SET COLLER 2 74 HL055.01.44 LIMIT SWITCH MTG.STOPPER 1 75 HL055.01.45 BEARING MIDDLE SPACER 2 76 HL055.01.46 LIMIT SW MOUNTING PLATE 2 77 HL055.01.47 FRONT WHEEL SIDE SPACER 2 78 HL055.01.48 REAR WHEEL SIDE SPACER 2 79 HL055.01.49 SENSOR MTG. BRACKET 4 80 HL055.01.50 DOG 1 81 HL055.01.51 RAIL-2 2 82 HL055.01.52 MOTOR MTG. PLATE 1 83 HL055.01.53 POWER PACK TANK 1 84 W75 U100 P80 B5B3+BN80A4 GEARED MOTOR, 0.55 KW, O/P RPM=14 1 2000 1155 648 800 A A SECTION A-A 33 36 53 59 65 84 6 22 D D SECTION D-D 5 50 20 19 17 62 11 63 19 20 21 25 56 74 55 9 32 54 28 67 10 35 34 42 61 4 72 77 70 18 46 78 16 48 75 45 73 51 80 47 76 71 30 31 64 B B SECTION B-B 66 38 27 39 24 C C SECTION C-C 42 43 2 58 41 37 E E SECTION E-E 40 23 44 60 29 7 8 26 49 14 15 12 13 1150 780 1750 3500 57 79 81 1 3 52 69 83 82 68 F I N A L

- 4. A 1 B C D 2 3 4 5 E F G H I 1 2 3 4 5 6 7 8 9 10 11 12 A B C D 6 7 8 9 10 E F G IF IN DOUBT, ASK ALL DIMN.ARE IN MM 11 12 H I HL055.01.00 SCISSOR LIFT-1 0.00 kg 27/10/21 27/10/21 27/10/21 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A1 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg A.M R.K ECTI SR. NO. ITEM CODE ITEM DESCRIPTION QTY 1 6208-ZZ 4 2 HYDRAULIC CYLINDER BORE-63x STROKE =195, PIN CENTRE TO CENTRE 475MM 2 3 PARALLEL KEY-8x7x124L 2 4 PARALLEL KEY-8x7x124L 1 5 POWER PACK 1 6 - SENSOR LIMIT SWITCH NG1-VS-510L24 WITH LED 24 V DC. 1 7 - SENSOR LIMIT SWITCH NG1-VS-510L24 WITH LED 24 V DC. 1 8 -- ALLN CSK M8x16( S .S ) 12 9 -- LOCK NUT M8 4 10 -- ALLAN CAP SCREW M6x30 2 11 -- CIRCLIP INTERNAL B-55 4 12 -- ALLEN CAP SCREW M10x30Lg. 20 13 -- BEARING DEEP GROOVE 6006ZZ 4 14 -- ALLAN CAP SCREW M10x20 32 15 -- Allan Csk M8x20 48 16 -- ALLAN CAP SCREW M8x20 20 17 -- ALLEN C'SUNK SCREW M6x10Lg. 28 18 -- ALLAN C'SUNK SCREW M6x16L 4 19 -- HEX BOLT M8x35 4 20 -- ALLAN CAP SCREW M5x10 4 21 -- ALLAN CAP SCREW M5x40 8 22 -- ALLAN CAP SCREW M6x16 8 23 -- ALLAN CAP SCREW M6x10L 8 24 -- ALLEN CAP SCREW M8 x 45Lg. 18 25 -- INT. CIRCLIP B-47 4 26 -- ALLAN C'SUNK SCREW M6x16L 56 27 -- ALLEN CAP SCREW M8x35 2 28 -- PLAIN BEARING BUSH 4 29 -- BALL BEARING 6005 4 30 -- BEARING SKF-6206 ZZ 4 31 1/2"-52 PITCHES - 660.4 LONG + 1 LINK DUPLEX CHAIN-1/2" 1 32 HL055.01.01 BOTTOM FRAME 1 33 HL055.01.02 BOTTOM RAIL 2 34 HL055.01.03 SCISSOR PLATE-1 2 35 HL055.01.04 SCISSOR PLATE-2 2 36 HL055.01.05 TOP FRAME 1 37 HL055.01.06 ROLLER 4 38 HL055.01.07 ROLLER PIN 4 39 HL055.01.08 ROLLER RETAINER 4 40 HL055.01.09 FIX PIVOT PIN 4 41 HL055.01.10 CENTER PIN 2 42 HL055.01.11 CENTER PIVOT RETAINER 6 43 HL055.01.12 BEARING BOSS 4 44 HL055.01.13 WHEEL BRACKET REAR SIDE 2 45 HL055.01.14 WHEEL PIN 2 46 HL055.01.15 DRIVEN WHEEL 2 47 HL055.01.16 WHEEL RETAINER 2 48 HL055.01.17 WHEEL SPACER 2 49 HL055.01.18 RAIL-1 2 50 HL055.01.19 RAIL ON TABLE 2 51 HL055.01.20 WHEEL SHAFT 1 52 HL055.01.21 SPROCKET REWORK 2 53 HL055.01.22 FRONT PIVOT BRACKET 1 54 HL055.01.23 REAR PIVOT BRACKET 1 55 HL055.01.24 STOPPER 3 56 HL055.01.25 STOPPER PAD 4 57 HL055.01.26 WHEEL STOPPER 6 58 HL055.01.27 CENTER PIVOT SPACER 2 59 HL055.01.28 TOP RAIL 2 60 HL055.01.29 REAR PIVOT LOCATOR 2 61 HL055.01.30 CYLINDER TOP PIN 4 62 HL055.01.31 CYLINDER TOP SPACER 8 63 HL055.01.32 DRIVE MOUNTING PLATE 1 64 HL055.01.33 BRACKET 1 65 HL055.01.34 POWER PACK MOUNT 4 66 HL055.01.35 DRIVING WHEEL 2 67 HL055.01.36 ROLLER RETAINER-2 4 68 HL055.01.37 TOP PLATE -1 1 69 HL055.01.38 SPROCKET RETAINER 1 70 HL055.01.39 GEARBOX-SHAFT 1 71 HL055.01.40 G.B. SHAFT RETAINER 3 72 HL055.01.41 WHEEL BRACKET FRONT SIDE 2 73 HL055.01.42 FRONT WHEEL SPACER 4 74 HL055.01.43 SET COLLER 2 75 HL055.01.44 LIMIT SWITCH MTG.STOPPER 1 76 HL055.01.45 BEARING MIDDLE SPACER 2 77 HL055.01.46 LIMIT SW MOUNTING PLATE 2 78 HL055.01.47 FRONT WHEEL SIDE SPACER 2 79 HL055.01.48 REAR WHEEL SIDE SPACER 2 80 HL055.01.49 SENSOR MTG. BRACKET 4 81 HL055.01.50 DOG 1 82 HL055.01.51 RAIL-2 2 83 W75 U100 P80 B5B3+BN80A4 GEARED MOTOR, 0.55 KW, O/P RPM=14 1 2000 1155 648 800 A A SECTION A-A 5 33 36 53 59 66 83 6 11 D D SECTION D-D 69 7 50 19 9 21 62 16 63 9 19 12 26 56 75 55 23 32 54 17 68 15 3 35 34 42 61 2 73 78 71 13 46 79 30 48 76 45 74 51 81 71 70 52 4 47 77 72 31 65 64 B B SECTION B-B 67 38 29 39 25 C C SECTION C-C 42 43 1 58 41 37 E E SECTION E-E 40 28 44 60 27 24 22 18 49 8 14 20 10 1150 780 1750 3854 3500 57 80 82 F I N A L

- 5. A 1 B C D 2 3 4 5 E F G H I 1 2 3 4 5 6 7 8 9 10 11 12 A B C D 6 7 8 9 10 E F G IF IN DOUBT, ASK ALL DIMN.ARE IN MM 11 12 H I SW 01 BOTTOM FRAME 73.97 kg M.S 05/09/21 05/09/21 05/09/21 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A1 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg PAINTING 1 : 5 - RK AM ECTI 530 ±0.5 = = (TYP.) 70 (TYP.) Sr. No. DESCRIPTION SIZE QTY. REMARK 1 PLATE 01 375 X 100 X 12 THK. 01 2 PLATE 02 100 X 75 X 12THK. 04 3 FBA.CHANNEL A 100 x 50 x6 THK.x 1750L 02 4 FBA.CHANNEL B 100 x 50 x6 THK.x 800L 02 5 PLATE 04 100 X 800 X 12THK. 02 6 PLATE 03 380 X 45 X 12THK. 04 7 FIX PIVOT 100 X 87 X 75 02 M6THRU` 08 NOS. NOTES :- 1.ALL JOINTS TO BE WELDED FILLET 5mm 2.EDGE PREPARATION TO BE DONE WHEREVER REQUIRED 503 ±0.2 = = DETAIL FROM ITEM NO -7 B B SECTION B-B 100 87 43.5 75 45 = = 45 = = 87 M8X 15 DEEP (04 NOS.) 75 25 40 +0.5 +0.4 = = 10 x 45° TYP. 15 x 45° TYP. M6THRU` (04 NOS.) ON PCD.45 O 30 +0.2 +0.1 THRU' (02 NOS) 80 28 70 ±0.1 A a 0.1 A 325 = = 450 450 75 (TYP.) 12 375 = = 12 800 ±1 700 = = 100 14 1553±0.5 = = 157 100 50 12 57 730±0.2 = = 70 (TYP.) 900 = = 100 (TYP.) 450 ±0.5 = = (TYP.) 155 ±0.1 (TYP.) 68 360±0.1 120 (TYP.) M6THRU` (08 NOS.) M10THRU` (16 NOS.) O 40THRU' 02 NOS. 350±0.2 = = 50 (TYP.) 1750±1 O 40THRU' 02 NOS. 1 2 5 6 3 4 7 380 = = 800 824 100 112 12 45 (TYP.) O9THRU` (8 NOS.) 45 533 ±0.2 = = 45 = = (TYP.) 150±0.2 = = 76 ±0.1 = = 25 400±0.5 (TYP.) 55 = = (TYP.) M10THRU` (16 NOS.) 72 R 15 (TYP.) 330 M10THRU` (4 NOS.) F I N A L

- 6. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.02 RAIL 0.69 kg EN-8 PLATING 02/11/21 02/11/21 - 1 :2 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg 02/11/21 A.M R.K ECTI - 400±0.2 20 120±0.1 (TYP) SIDE VIEW 1 28 8 O7THRU` (04 NOS.) CSKO13X90° NOTE- TO BE TOUGHNED 28 ~ 30 HRC. 14 F I N A L

- 7. A 1 C B 2 3 4 E D F 1 2 3 4 5 6 7 8 A B C IF IN DOUBT, ASK ALL DIMN.ARE IN MM 5 6 7 D E 8 F HL055.01.03.01 SCISSOR PLATE-1 27.82 kg M.S PAINTING A.M 5/11/21 1 : 5 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A3 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg 5/11/21 - R.K 5/11/21 ECTI 105±0.2 = = 70 ±0.2 = = A A SECTION A-A 670±0.2 34 H7 O TYP. 30 (04 NOS.)M8THRU` ON PCD 114u0.1 M10THRU` 04 NOS. 150 = = 86° M8THRU`(04 NOS.) ON PCD.54 1570±0.3 = = O 97 +0.1 +0.2 THRU' Sr. No. DESCRIPTION SIZE QTY. REMARK 1 PLATE USE PROFILE 01 2 BOSS DIA 58 X 30 02 NOTES :- 1. ALL JOINTS TO BE FULL WELDED FILLET 5 mm. 2. EDGE PREPARATION TO BE DONE WHEREVER REQUIRED. ITEM NO-2 FACES TO BE PRE-MACHINED AND WELDED ON PLATE, THEN BORE WITH PLATE 1 1655±0.5 22 r0.5 r0.5 16 200 DETAIL FOR ITEM NO-02 48 -0.1 -0.2 O 58 O 8 30 O 34 H7 45° 2 1 x 45° CHF' (TYP.) O 38H7 THRU' 1 1 72±0.2 149 M10XTHRU' (2NOS,) 1 F I N A L

- 8. A 1 C B 2 3 4 E D F 1 2 3 4 5 6 7 8 A B C IF IN DOUBT, ASK ALL DIMN.ARE IN MM 5 6 7 D E 8 F HL055.01.03.01 SCISSOR PLATE-1 27.82 kg M.S PAINTING A.M 5/10/21 1 : 5 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A3 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg 5/10/21 - R.K 5/10/21 ECTI 105±0.2 = = 70 ±0.2 = = A A SECTION A-A 670±0.2 34 H7 O TYP. 30 (04 NOS.)M8THRU` ON PCD 114u0.1 M10THRU` 04 NOS. 150 = = 86° M8THRU`(04 NOS.) ON PCD.54 1570±0.3 = = O 97 +0.1 +0.2 THRU' Sr. No. DESCRIPTION SIZE QTY. REMARK 1 PLATE USE PROFILE 01 2 BOSS DIA 58 X 30 02 NOTES :- 1. ALL JOINTS TO BE FULL WELDED FILLET 5 mm. 2. EDGE PREPARATION TO BE DONE WHEREVER REQUIRED. ITEM NO-2 FACES TO BE PRE-MACHINED AND WELDED ON PLATE, THEN BORE WITH PLATE 1 1655±0.5 22 r0.5 r0.5 16 200 DETAIL FOR ITEM NO-02 48 -0.1 -0.2 O 58 O 8 30 O 34 H7 45° 2 1 x 45° CHF' (TYP.) O 38H7 THRU' 1 1 72±0.2 149 M10XTHRU' (2NOS,) 1 F I N A L

- 9. A 1 C B 2 3 4 E D F 1 2 3 4 5 6 7 8 A B C IF IN DOUBT, ASK ALL DIMN.ARE IN MM 5 6 7 D E 8 F HL055.01.03 SCISSOR PLATE-1 27.82 kg M.S PAINTING A.M 02/11/21 1 : 5 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A3 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg 02/11/21 - R.K 02/11/21 ECTI 105±0.2 = = 70 ±0.2 = = A A SECTION A-A 670±0.2 34 H7 O TYP. 30 (04 NOS.)M8THRU` ON PCD 114u0.1 M10THRU` 04 NOS. 150 = = 86° M8THRU`(04 NOS.) ON PCD.52 1570±0.3 = = O 97 +0.1 +0.2 THRU' O 32 H7 THRU' Sr. No. DESCRIPTION SIZE QTY. REMARK 1 PLATE USE PROFILE 01 2 BOSS DIA 58 X 30 02 NOTES :- 1. ALL JOINTS TO BE FULL WELDED FILLET 5 mm. 2. EDGE PREPARATION TO BE DONE WHEREVER REQUIRED. ITEM NO-2 FACES TO BE PRE-MACHINED AND WELDED ON PLATE, THEN BORE WITH PLATE 1 1655±0.5 22 r0.5 r0.5 16 200 DETAIL FOR ITEM NO-02 48 -0.1 -0.2 O 58 O 8 30 O 34 H7 45° 2 1 x 45° CHF' (TYP.) F I N A L

- 10. A 1 C B 2 3 4 E D F 1 2 3 4 5 6 7 8 A B C IF IN DOUBT, ASK ALL DIMN.ARE IN MM 5 6 7 D E 8 F HL055.01.04.01 SCISSOR PLATE-2 26.27 kg M.S PAINTING A.M 5/11/21 5/11/21 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A3 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg 5/11/21 - R.K 1 : 5 ECTI A A SECTION A-A 1570±0.3 = = Sr. No. DESCRIPTION SIZE QTY. REMARK 1 PLATE USE PROFILE 01 2 BOSS DIA 58 X 30 02 NOTES :- 1. ALL JOINTS TO BE FULL WELDED FILLET 5 mm. 2. EDGE PREPARATION TO BE DONE WHEREVER REQUIRED. r0.5 r0.5 1 ITEM NO-2 FACES TO BE PRE-MACHINED AND WELDED ON PLATE, THEN BORE WITH PLATE DETAIL FOR ITEM NO-02 48 -0.2 -0.1 O 8 58 O 30 O 34 H7 200 16 150 = = O 97 +0.2 +0.1 110 ±0.1 = = 87.5±0.1 50 M10THRU` (04 NOS.) 30 22 34 H7 O TYP. 1655±0.5 M8THRU`(04 NOS.) ON EQUISPACED PCD. 114u0.1 1 x 45° CHF' (TYP.) 72±0.1 = = (TYP.) 149 (TYP.) M10XTHRU' (4NOS,) 1 F I N A L

- 11. A 1 C B 2 3 4 E D F 1 2 3 4 5 6 7 8 A B C IF IN DOUBT, ASK ALL DIMN.ARE IN MM 5 6 7 D E 8 F HL055.01.04.01 SCISSOR PLATE-2 26.27 kg M.S PAINTING R.K 5/11/21 5/11/21 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A3 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg 5/11/21 - A.M 1 : 5 ECTI A A SECTION A-A 1570±0.3 = = Sr. No. DESCRIPTION SIZE QTY. REMARK 1 PLATE USE PROFILE 01 2 BOSS DIA 58 X 30 02 NOTES :- 1. ALL JOINTS TO BE FULL WELDED FILLET 5 mm. 2. EDGE PREPARATION TO BE DONE WHEREVER REQUIRED. r0.5 r0.5 1 ITEM NO-2 FACES TO BE PRE-MACHINED AND WELDED ON PLATE, THEN BORE WITH PLATE DETAIL FOR ITEM NO-02 48 -0.2 -0.1 O 8 58 O 30 O 34 H7 200 16 150 = = O 97 +0.2 +0.1 110 ±0.1 = = 87.5±0.1 50 M10THRU` (04 NOS.) 30 22 34 H7 O TYP. 1655±0.5 M8THRU`(04 NOS.) ON EQUISPACED PCD. 114u0.1 1 x 45° CHF' (TYP.) 72±0.1 = = (TYP.) 149 (TYP.) M10XTHRU' (4NOS,) 1 F I N A L

- 12. A 1 C B 2 3 4 E D F 1 2 3 4 5 6 7 8 A B C IF IN DOUBT, ASK ALL DIMN.ARE IN MM 5 6 7 D E 8 F HL055.01.04 SCISSOR PLATE-2 26.27 kg M.S PAINTING A.M 02/11/21 02/11/21 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A3 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg 02/11/21 - R.K 1 : 5 ECTI A A SECTION A-A 1570±0.3 = = Sr. No. DESCRIPTION SIZE QTY. REMARK 1 PLATE USE PROFILE 01 2 BOSS DIA 58 X 30 02 NOTES :- 1. ALL JOINTS TO BE FULL WELDED FILLET 5 mm. 2. EDGE PREPARATION TO BE DONE WHEREVER REQUIRED. r0.5 r0.5 1 ITEM NO-2 FACES TO BE PRE-MACHINED AND WELDED ON PLATE, THEN BORE WITH PLATE DETAIL FOR ITEM NO-02 48 -0.2 -0.1 O 8 58 O 30 O 34 H7 2 45° 200 16 150 = = O 97 +0.2 +0.1 110 ±0.1 = = 87.5±0.1 50 M10THRU` (04 NOS.) 30 22 34 H7 O TYP. 1655±0.5 M8THRU`(04 NOS.) ON PCD 114u0.1 1 x 45° CHF' (TYP.) F I N A L

- 13. A 1 B C D 2 3 4 5 E F G H I 1 2 3 4 5 6 7 8 9 10 11 12 A B C D 6 7 8 9 10 E F G IF IN DOUBT, ASK ALL DIMN.ARE IN MM 11 12 H I HL055.01.05 TOP FRAME 181.74 kg M.S 03/11/21 03/11/21 - MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A1 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg PAINTING 1 : 5 03/11/21 A.M R.K ECTI Sr. No. DESCRIPTION SIZE QTY. REMARK 1 FBA.CHANNEL A 100 x 50 x6 THK.x 1750L 02 2 FBA.CHANNEL B 100 x 50 x6 THK.x 800L 02 3 L'SECTION REF.DRG. 02 4 FBA.CHANNEL D 100 x 50 x6 THK.x 750L 01 5 FIX PIVOT 100 X 87 X 75 02 NOTES :- 1.ALL JOINTS TO BE WELDED FILLET 5mm 2.EDGE PREPARATION TO BE DONE WHEREVER REQUIRED DETAIL FROM ITEM NO -7 B B SECTION B-B 100 87 43.5 75 45 = = 45 = = 87 M8X 15 DEEP (04 NOS.) 75 25 40 +0.4 +0.5 = = 10 x 45° TYP. 15 x 45° TYP. M6THRU` (04 NOS.) ON PCD.45 O 30 +0.2 +0.1 THRU' (02 NOS) 70 ±0.1 A a 0.1 A 120 (TYP.) 360±0.1 = = M6THRU` (42 NOS.) 125 300±0.1 (TYP.) 1 2 3 4 5 820 100 68 M6THRU` (08 NOS.) 557 = = 800 ±1 = = 215 ±0.1 = = (TYP.) 100 45 = = 45 587 ±0.2 = = 45 O9THRU` (08 NOS.) 100 720±0.2 120 (TYP.) 158 ±0.1 (TYP.) 120 76 36 20 100 69 (TYP.) 770 1750±1 = = O 40THRU' (4 NOS.) DETAIL FOR ITEM NO.3 6 R 6 100 50 820 O 45THRU' 25 50 44 F I N A L

- 14. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.06 ROLLER 0.47 kg EN-8 PLATING 02/11/21 02/11/21 - 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg ( ) 02/11/21 A.M R.K ECTI - A A SECTION A-A 36 O 5 27 68±0.1 O U'CUT (MIN) NOTE :- TO BE TOUGHEN TO 28 30 HRc. ~ 78 O 47 H7 O 1.85 H13 A 0.5 x 45° CHF' (TYP.) 49.5 H12 O 12 ±0.1 5 n 0.1 A F I N A L

- 15. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.07 ROLLER PIN 0.42 kg EN-8 PLATING 22/10/21 22/10/21 22/10/21 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg ( ) R.K A.M - ECTI - A A SECTION A-A 25 h6 O 33 O 8 15 = = M6X 12 DEEP (04 NOS.) 45 O A NOTE :- TO BE TOUGHEN TO 28 30 HRc. ~ 12 60 ±0.1 3 x 15° CHF' (TYP.) 34 g6 O 29 -0.5 -0.2 11.5 n 0.1 A a 0.1 A F I N A L

- 16. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.08 ROLLER RETAINER 0.03 kg M.S PLATING 3/11/21 3/11/21 3/11/21 2 : 1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg - R.K A.M ECTI A A SECTION A-A 6 1 x 45° CHF' TYP. O7THRU` (02 NOS.) CSK O13X90° 15 = = 32 O F I N A L

- 17. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.09 FIX PIVOT PIN 0.63 kg EN-8 PLATING 02/11/21 02/11/21 - 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg ( ) 02/11/21 A.M R.K ECTI 10 88 30 g6 O 60 O 3 x 15° CHF' (TYP.) O7THRU` CSKO 13X90° 04 NOS. NO PCD.45u0.2 1 CH' X45v TYP. NOTE :- TO BE TOUGHEN TO 28 30 HRc. ~ U' CUT (MIN) 78 -0.5 -0.2 F I N A L

- 18. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.10 CENTER PIN 0.55 kg EN-8 PLATING 3/11/21 3/11/21 3/11/21 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg ( ) - R.K A.M ECTI A A SECTION A-A 53 40 h6 O 18 = = M8X 15 DEEP ( 02 NOS.) NOTE :- TO BE TOUGHEN TO 28 30 HRc. ~ 1 x 45° CHF' (TYP.) 3 x 15° CHF' (TYP.) U'CUT (MIN) 48 O 43 -0.2 -0.1 10 n 0.1 A A F I N A L

- 19. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.11 CENTER PIVOT RETAINER 0.12 kg M.S PLATING 3/11/21 3/11/21 3/11/21 2 : 1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg - R.K A.M ECTI F I N A L

- 20. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.12 BEARING BOSS 1.01 kg M.S PLATING 5/11/21 5/11/21 5/11/21 1 : 2 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg - R.K A.M ( ) ECTI A A SECTION A-A 8 27 70 O 80 H7 O O9THRU` CSK O17X90v 04 NOS. ON PCD 114u0.1 20 97 -0.1 -0.2 O n 0.1 A a 0.1 A A n 0.05 A 138 O F I N A L

- 21. A 1 C B 2 3 4 E D F 1 2 3 4 5 6 7 8 A B C IF IN DOUBT, ASK ALL DIMN.ARE IN MM 5 6 7 D E 8 F HL055.01.13 WHEEL BRACKET REAR SIDE 3.76 kg M.S PAINTING 02/11/21 02/11/21 - 1 :2 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A3 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg 02/11/21 A.M R.K ECTI - 155±0.2 = = 70 ±0.1 = = 102 175 2 x 45° CHF' TYP. O11THRU` (04 NOS.) 93 58 ±0.1 10 125 = = 175 87.5 102 48 +0.2 +0.1 = = 93 83 O 30 H7THRU' (02 NOS.) Sr. No. DESCRIPTION SIZE QTY. REMARK 1 PLATE-A 175 X 102 X 10THK. 01 2 PLATE-B 125 X 83 X 22THK. 02 DETAIL FOF ITEM NO-02 125 83 25 22 1 2 NOTES :- 1. ALL JOINTS TO BE FULL WELDED FILLET 5 mm. 2. EDGE PREPARATION TO BE DONE WHEREVER REQUIRED. A i 0.2 A F I N A L

- 22. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.14 WHEEL PIN 0.58 kg EN-8 PLATING - 3/11/21 3/11/21 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg R.K 3/11/21 A.M ( ) ECTI - 42 O 30 h6 O 3 x 45° CH (TYP.) 98 8 2 x 15° CHF' (TYP.) 15 = = M6X 12 DEEP (02 NOS.) 90 -0.5 -0.2 NOTE :- TO BE TOUGHEN TO 28 30 HRc. ~ F I N A L

- 23. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.15 DRIVEN WHEEL 0.81 kg EN-8 PLATING 3/11/21 3/11/21 3/11/21 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg - R.K A.M ( ) ECTI - A A SECTION A-A 42 80 O 88 O 62 H7 O 10 32 10 ±0.1 1 x 45° CH (TYP.) A NOTE :- TO BE TOUGHEN TO 28 30 HRc. ~ 52 O 62 H7 a 0.1 A 16 ±0.1 (TYP.) n 0.1 A n 0.1 A F I N A L

- 24. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.16 WHEEL RETAINER 0.05 kg M.S PLATING 3/11/21 3/11/21 3/11/21 2 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg - R.K A.M ECTI - A A SECTION A-A 6 38 O 15 = = 1 x 45° CH (TYP.) O7THRU` (02 NOS.) CSK O13X90° F I N A L

- 25. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.17 WHEEL SPACER 0.02 kg M.S PLATING 02/11/21 02/11/21 - 2 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg 02/11/21 R.K A.M ECTI - A A SECTION A-A 40 O 30 +0.2 +0.1 O 4 0.5 x 45° CHF' (TYP.) A i 0.1 A F I N A L

- 26. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.18 RAIL-1 16.57 kg M.S PAINTING 02/11/21 02/11/21 - 1 :5 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg 02/11/21 A.M R.K ( ) ~ ECTI - 40 (TYP.) 2000±0.5 92 8 92 650 (TYP.) 32 A DETAIL A 60 32 O18THRU` (04 NOS.) 5 20 40 Sr. No. DESCRIPTION SIZE QTY. REMARK 1 SQ.ROAD 32 X 32 X2000L 01 2 PLATE 60 X 40 X 8THK. 04 NOTES :- 1. ALL JOINTS TO BE FULL WELDED FILLET 5 mm. 2. EDGE PREPARATION TO BE DONE WHEREVER REQUIRED. F I N A L

- 27. A 1 C B 2 3 4 E D F 1 2 3 4 5 6 7 8 A B C IF IN DOUBT, ASK ALL DIMN.ARE IN MM 5 6 7 D E 8 F HL055.01.19 RAIL ON TABLE 8.59 kg M.S PAINTING 03/11/21 03/11/21 - 1 :5 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A3 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg 03/11/21 A.M R.K ( ) ECTI - 1750±0.2 50 1650±0.2 150 (TYP.) 32 = = 20 32 9THRU` C`BORE 17x2 DEEP(16 NOS.) CSK O17X90° 2 F I N A L

- 28. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.20 WHEEL SHAFT 4.84 kg EN-8 PLATING A.M 01/11/21 01/11/21 1 :2 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg ( ) 01/11/21 - R.K ECTI - 30 g6 882 -0.5 -0.2 22 34 254 52 464 34 15 = = M6X 12 DEEP (04 NOS.) A A SECTION A-A 8 N9 = = (TYP.) 26 +0.0 -0.1 (TYP.) R 4 (TYP.) 1 x 45° CHF' (TYP.) t0.2 2) STD. SHAFT OF REQUIRED SIZE CAN BE PROCURED FROM FLURO NOTE :- 1) TO BE TOUGHEN TO 28 ~ 30 HRc. F I N A L

- 29. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.21 SPROCKET REWORK 0.50 kg PLATING A.M 02/11/21 02/11/21 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg 02/11/21 - R.K STD. ( ) ECTI A A SECTION A-A 8 Js9 = = 33.3 +0.1 -0.0 30 H7 O 50 O 35 7 (TYP.) 14 TO BE REWORK FROM STD. SPROCKET 1/2" DUPLEX-17 TEETH -NU-TECK MAKE 1 x 45° CHF' (TYP.) 3.5 F I N A L

- 30. ALL DIMN.ARE IN MM IF IN DOUBT, ASK F 8 E D 7 6 5 C B A 8 7 6 5 4 3 2 1 F E D 4 3 2 C B 1 A HL055.01.22.01 FRONT PIVOT BRACKET 18.90 kg M.S PLATING 16.11.21 16.11.21 16.11.21 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A2 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg ( ) - R.K A.M ECTI DETAIL FROM ITEM NO -4 75 = = 160 = = 180 75 = = 60 15 90 135 1 2 4 16 16 110 ±0.1 = = 40 = = 73±0.2 140 O 30THRU' (04 NOS.) R 30 3 Sr. No. DESCRIPTION SIZE QTY. REMARK 1 PLATE 01 160 X 75 X 16THK. 02 2 PLATE 02 540 x 75 x 8THK. 02 3 PLATE 03 540 x 40 x 8THK. 02 4 PLATE 04 180 X 135 X 16THK. 04 160 564 -0.2 -0.4 = = 12 540 = = 16 4 i 0.1 i 0.1 282±0.2 = = 58 +0.2 +0.1 (TYP.) 102.5 ±0.2 50±0.1 = = 75 O11THRU` (08 NOS.) 90° 205 NOTE :- 1) - ALL JOINTS TO BE WELDED - ALL OVER FILLET 5mm. - WELDING SHOULD BE NEAT & CLEAN 2) - SUITABLE EDGE PREPARATION TO BE DONE. 3) - TO BE STRESS RELIEVED AFTER WELDING. 53 70 A n 0.2 A 1 F I N A L

- 31. ALL DIMN.ARE IN MM IF IN DOUBT, ASK F 8 E D 7 6 5 C B A 8 7 6 5 4 3 2 1 F E D 4 3 2 C B 1 A HL055.01.23.01 REAR PIVOT BRACKET 16.96 kg M.S PAINTING 16.11.21 16.11.21 - 1 :2 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A2 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg 16.11.21 A.M R.K ECTI 614 -0.2 -0.4 = = 90 = = 90 = = 70 ±0.2 = = 105±0.2 = = 125 O 11THRU' 04 NOS. 3 x 45° TYP. 1 2 4 3 56 = = 75 = = 40 12 590 = = 82.5±0.2 175 113 O 30 H7THRU' (04 NOS.) i 0.2 A A Sr. No. DESCRIPTION SIZE QTY. REMARK 1 PLATE 01 125 X 90 X12 THK. 02 2 PLATE 02 590 x 75 x 8 THK. 02 3 PLATE 03 590 x40 x 8 THK. 02 4 PROFILE PLATE 205 X 135 X 16THK. 04 PROFILE CUT 58 +0.2 +0.1 (TYP.) NOTE :- 1) - ALL JOINTS TO BE WELDED - ALL OVER FILLET 5mm. - WELDING SHOULD BE NEAT & CLEAN 2) - SUITABLE EDGE PREPARATION TO BE DONE. 3) - TO BE STRESS RELIEVED AFTER WELDING. O 32 +0.2 +0.1 THRU' (02 NOS.) i 0.1 i 0.1 43 ±0.2 12 282 = = DETAIL FOR ITEM NO-4 120 30 141 40 56 75 150 1 F I N A L

- 32. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.24 STOPPER 0.65 kg M.S PAINTING 3/11/21 3/11/21 3/11/21 1 :2 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg - R.K A.M ( ) ECTI - Sr. No. DESCRIPTION SIZE QTY. REMARK 1 PLATE 01 90 X 45 X 6THK. 01 2 PLATE 02 40 x40 x 10 THK. 01 3 SQ. TUBE 40 X 40 X 4THK. X 105L 01 NOTES :- 1. ALL JOINTS TO BE FULL WELDED FILLET 5 mm. 2. EDGE PREPARATION TO BE DONE WHEREVER REQUIRED. 90 = = 70 ±0.2 = = 45 40 = = 18 = = 40 O7THRU` 02 NOS. 121±0.5 6 M6THRU` (02 NOS.) 40 115 10 1 3 2 3 x 45° CH. (TYP.) F I N A L

- 33. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.25 STOPPER PAD 0.11 kg NYLON PLATING 3/11/21 3/11/21 3/11/21 2 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg - R.K A.M ECTI - A A SECTION A-A 20 40 40 18 = = 10 4 2 x 45° CHF' (TYP.) O7THRU` (02 NOS.) CSK O13X90° MATERIAL:- NYLON 70 SHA TO BE USED. F I N A L

- 34. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.26 WHEEL STOPPER 0.73 kg M.S PLATING - 3/11/21 3/11/21 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg R.K A.M 3/11/21 ECTI - 75 32 50 = = 45 O9THRU`(03 NOS.) C`BORE O14x20 DEEP 16 75 2 x 45° CHF' (TYP.) F I N A L

- 35. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.27 CENTER PIVOT SPACER 0.05 kg M.S PLATING 3/10/21 3/10/21 3/10/21 2 : 1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg - R.K A.M ( ) ECTI A A SECTION A-A 7 ±0.1 52 -0.5 -0.2 O 40 +0.2 +0.1 O 1 x 45° CHF' (TYP.) A i 0.1 A F I N A L

- 36. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.28 TOP RAIL 1.39 kg EN-8 PLATING 02/11/21 02/11/21 - 1 :2 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg 02/11/21 A.M R.K ECTI 700±0.5 SIDE VIEW 22 12 NOTE- TO BE TOUGHNED 28 ~ 30 HRC. 3 x 45° CHF' 2 7THRU` C`BORE 13x2 DEEP (06 NOS.) 120±0.1 = = (TYP.) 11 F I N A L

- 37. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.29 REAR PIVOT LOCATOR 0.54 kg EN-8 PLATING 02/11/21 02/11/21 - 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg 02/11/21 A.M R.K ECTI A A SECTION A-A 32 -0.1 -0.2 O 50 10 3 x 15° TYP. 1 x 45° TYP. 72 O O9THRU` CSKO 17X90° 04 NOS. ON PCD 52 NOTE :- TO BE TOUGHEN TO 28 30 HRc. ~ U' CUT MIN A n 0.1 A 40 -0.5 -0.2 F I N A L

- 38. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.30.01 CYLINDER TOP PIN 0.63 kg EN-8 PLATING 02/11/21 02/11/21 - 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg ( ) 02/11/21 A.M R.K ECTI A A SECTION A-A 30 g6 O 48 O 100 10 3 x 15° TYP. 18 = = M8X 15 DEEP (02 NOS.) n 0.1 A A NOTE :- TO BE TOUGHEN TO 28 30 HRc. ~ 90 ±0.1 1. F I N A L

- 39. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.31.01 CYLINDER TOP SPACER 0.05 kg M.S PLATING 16.11.21 16.11.21 - 2 : 1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg 16.11.21 A.M R.K ( ) ECTI A A SECTION A-A 10 ±0.1 42 O 30 +0.2 +0.1 O 0.5 x 45° TYP. A i 0.1 A 1 F I N A L

- 40. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.32 DRIVE MOUNTING PLATE 3.39 kg M.S PAINTING A.M 01/11/21 01/11/21 1 :2 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg ( ) 01/11/21 - R.K ECTI 125 = = 225 100 82 ±0.2 = = 20 127 ±0.2 200±0.2 = = 215 115 3 x 45° CHF' (TYP.) 12 R 10 (TYP.) M8THRU` (6 NOS.) 150±0.2 = = 12 76 ±0.1 30 O11THRU` (04 NOS.) 28 M10THRU` (4 NOS.) F I N A L

- 41. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.33 BRACKET 0.61 kg M.S PAINTING 02/11/21 02/11/21 - 1 :1 MATERIAL:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg 02/11/21 A.M R.K ECTI 25 100 100 25 12.5 30 25 12.5 20 x 45° CHF' (TYP.) 65 25 12.5 12 O 7THRU' (02 NOS.) O 9THRU' (02 NOS.) 13 F I N A L

- 42. ALL DIMN.ARE IN MM IF IN DOUBT, ASK F 8 E D 7 6 5 C B A 8 7 6 5 4 3 2 1 F E D 4 3 2 C B 1 A HL055.01.-34.REV 01 POWER PACK MOUNT 5.88 kg M.S PAINTING 17/11/21 17/11/21 17/11/21 1 : 2 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A2 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg - R.K A.M ( ) ~ ECTI 572 50 ±0.1 = = 75 12 100 90 202 60 12 500 10 375 425 50±0.1 = = 60 ±0.1 82 12 = = 12 150 202 75 40 O11THRU` (04 NOS.) 3 x 45° CHF' (TYP.) O11THRU` (02 NOS.) DETAIL FOR ITEM NO-04 50 90 50 425 40 R 25 (TYP.) 12 Sr. No. DESCRIPTION SIZE QTY. REMARK 1 PLATE 01 150 X 75 X 12THK. 01 2 PLATE 02 60 X 75X 12THK. 01 3 PLATE 03 512 X 75 X 12THK. 01 4 RIB 425 X 90 X 12THK. 01 1 2 3 4 444±0.2 50 ±0.1 OM8THRU` (04 NOS.) 28 40 DO NOT WELD NOTES :- 1. ALL JOINTS TO BE FULL WELDED FILLET 5 mm. 2. EDGE PREPARATION TO BE DONE WHEREVER REQUIRED. F I N A L

- 43. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.35 DRIVING WHEEL 1.49 kg EN-8 PLATING A.M 19/11/21 19/11/21 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg 19/11/21 - R.K ( ) ECTI A A SECTION A-A 8 Js9 = = 33.3 +0.1 -0.0 30 H7 O 88 O 80 O 10 42 ±0.1 1 x 45° CHF' (TYP.) NOTE :- TO BE TOUGHEN TO 28 30 HRc. ~ F I N A L

- 44. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.36 ROLLER RETAINER-2 0.07 kg M.S PLATING 3/11/21 3/11/21 3/11/21 2 : 1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg - R.K A.M ECTI - A A SECTION A-A 44 O 6 1 x 45° CHF' (TYP.) 15 = = O7THRU` (02 NOS.) CSK O13X90° F I N A L

- 45. ALL DIMN.ARE IN MM IF IN DOUBT, ASK F 8 E D 7 6 5 C B A 8 7 6 5 4 3 2 1 F E D 4 3 2 C B 1 A HL055.01.37 TOP PLATE -1 87.60 kg M.S PAINTING 3/10/21 3/10/21 3/10/21 1 : 5 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A2 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg - R.K A.M ECTI X1 Y1 Hole Table Hole X Y Callout 1 A.1 1710 430 Ø7XTHRU'X CSK.Ø13X90° A.2 0 645 Ø7XTHRU'X CSK.Ø13X90° A.3 1710 645 Ø7XTHRU'X CSK.Ø13X90° A.4 0 215 Ø7XTHRU'X CSK.Ø13X90° A.5 1710 215 Ø7XTHRU'X CSK.Ø13X90° A.6 0 430 Ø7XTHRU'X CSK.Ø13X90° A.7 1005 702,5 Ø7XTHRU'X CSK.Ø13X90° A.8 1305 702,5 Ø7XTHRU'X CSK.Ø13X90° A.9 1605 702,5 Ø7XTHRU'X CSK.Ø13X90° A.10 105 702,5 Ø7XTHRU'X CSK.Ø13X90° A.11 405 702,5 Ø7XTHRU'X CSK.Ø13X90° A.12 705 702,5 Ø7XTHRU'X CSK.Ø13X90° A.13 1605 -57,5 Ø7XTHRU'X CSK.Ø13X90° A.14 1305 -57,5 Ø7XTHRU'X CSK.Ø13X90° A.15 1710 0 Ø7XTHRU'X CSK.Ø13X90° A.16 0 0 Ø7XTHRU'X CSK.Ø13X90° Hole Table Hole X Y Callout 1 A.17 405 -57,5 Ø7XTHRU'X CSK.Ø13X90° A.18 105 -57,5 Ø7XTHRU'X CSK.Ø13X90° A.19 1005 -57,5 Ø7XTHRU'X CSK.Ø13X90° A.20 705 -57,5 Ø7XTHRU'X CSK.Ø13X90° B.1 930 572,5 M8X THRU' B.2 1080 572,5 M8X THRU' B.3 630 572,5 M8X THRU' B.4 780 572,5 M8X THRU' B.5 1530 572,5 M8X THRU' B.6 1680 572,5 M8X THRU' B.7 1230 572,5 M8X THRU' B.8 1380 572,5 M8X THRU' B.9 1380 72,5 M8X THRU' B.10 1230 72,5 M8X THRU' B.11 1680 72,5 M8X THRU' B.12 1530 72,5 M8X THRU' Hole Table Hole X Y Callout 1 B.13 780 72,5 M8X THRU' B.14 630 72,5 M8X THRU' B.15 1080 72,5 M8X THRU' B.16 930 72,5 M8X THRU' B.17 180 572,5 M8X THRU' B.18 30 572,5 M8X THRU' B.19 480 572,5 M8X THRU' B.20 330 572,5 M8X THRU' B.21 330 72,5 M8X THRU' B.22 480 72,5 M8X THRU' B.23 30 72,5 M8X THRU' B.24 180 72,5 M8X THRU' A.18 A.17 A.20 A.19 A.14 A.13 A.16 A.15 B.23 B.24 B.21 B.22 B.14 B.13 B.16 B.15 B.10 B.9 B.12 B.11 A.4 A.5 A.6 A.1 B.18 B.17 B.20 B.19 B.3 B.4 B.1 B.2 B.7 B.8 B.5 B.6 A.2 A.3 A.10 A.11 A.12 A.7 A.8 A.9 10 x 45° CH. (TYP.) 8 800 ±0.5 NOTE- ALL HOLES CENTER DISTANCES.TO BE MAINTAINED WITHIN u0.1mm 1750±1 77.5 20 F I N A L

- 46. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.38 SPROCKET RETAINER 0.03 kg M.S PLATING 10/11/21 10/11/21 10/11/21 2 : 1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg - R.K A.M ECTI - A A SECTION A-A 33 O 6 2 x 45° CHF' (TYP.) O7THRU` (02 NOS.) CSK O13X90° 15 = = F I N A L

- 47. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.39 GEARBOX-SHAFT 0.93 kg EN-8 PLATING - 5/11/21 5/11/21 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg R.K A.M 5/11/21 ( ) ECTI - BOTTOM VIEW 30 h6 O 37 O 35 -0.5 -0.2 127 -0.5 -0.2 10 172 ±0.2 R 4 (TYP.) 30 g6 O 123 1 x 45° CHF' (TYP.) n 0.2 A n 0.2 A A 31 8 N9 = = 26 +0.0 -0.1 M6X 12 DEEP (02 NOS.) 15 = = 8 N9 = = 26 +0.0 -0.1 M6X 12 DEEP (02 NOS.) a 0.1 A 15 = = NOTE :- TO BE TOUGHEN TO 28 30 HRc. ~ F I N A L

- 48. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.40 G.B. SHAFT RETAINER 0.05 kg M.S. PLATING - 10/11/21 10/11/21 2 : 1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg A.M R.K 10/11/21 ECTI - A A SECTION A-A 38 O 6 2 x 45° CHF' (TYP.) 15 = = O7THRU` (02 NOS.) CSK O13X90° F I N A L

- 49. A 1 C B 2 3 4 E D F 1 2 3 4 5 6 7 8 A B C IF IN DOUBT, ASK ALL DIMN.ARE IN MM 5 6 7 D E 8 F HL055.01.41 WHEEL BRACKET FRONT SIDE 3.05 kg M.S PAINTING 02/11/21 02/11/21 - 1 :2 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A3 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg 02/11/21 A.M R.K ( ) ECTI - Sr. No. DESCRIPTION SIZE QTY. REMARK 1 PLATE-A 175 X 102 X 10THK. 01 2 PLATE-B 115 X 83 X 22THK. 02 1 2 NOTES :- 1. ALL JOINTS TO BE FULL WELDED FILLET 5 mm. 2. EDGE PREPARATION TO BE DONE WHEREVER REQUIRED. A A SECTION A-A 70±0.1 = = 155 ±0.1 = = 102 175 2 x 45° CHF' (TYP.) 58±0.1 175 = = 93 10 55 H7 O 47 O (TYP.) 102 93 83 48 +0.2 +0.1 = = A 115 22 83 25 58 H12 O (TYP.) 56 ±0.1 = = 13 +0.2 +0.1 (TYP.) 55 H7 O a 0.1 A i 0.2 2.15 H13 (TYP.) n 0.2 A 115 = = O11THRU` 4 NOS. F I N A L

- 50. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.42 FRONT WHEEL SPACER 0.03 kg M.S PLATING 3/11/21 3/11/21 3/11/21 2 : 1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg - R.K A.M ECTI - A A SECTION A-A 8 ±0.1 40 O 30 +0.1 +0.2 O 0.5 x 45° CHF' (TYP.) A i 0.1 A F I N A L

- 51. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.43 SET COLLER 0.28 kg M.S PLATING - 5/11/21 5/11/21 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg R.K A.M 5/11/21 ECTI - 2 = = 18 60 24 O7THRU` C`BORE O 11x20 DEEP 30 +0.10 +0.05 O 24 1 x 45° (TYP.) M6THRU` F I N A L

- 52. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.44 LIMIT SWITCH MTG.STOPPER 0.65 kg M.S PAINTING 3/11/21 3/11/21 3/11/21 1 :2 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg - R.K A.M ECTI Sr. No. DESCRIPTION SIZE QTY. REMARK 1 PLATE 01 90 X 45 X 6THK. 01 2 PLATE 02 40 x40 x 10 THK. 01 3 SQ. TUBE 40 X 40 X 4THK. X 105L 01 NOTES :- 1. ALL JOINTS TO BE FULL WELDED FILLET 5 mm. 2. EDGE PREPARATION TO BE DONE WHEREVER REQUIRED. 90 = = 70 ±0.2 = = 45 40 = = 18 = = 40 O7THRU` 02 NOS. M6THRU` (02 NOS.) 1 3 2 3 x 45° CH. (TYP.) 10 40 6 121±0.5 115 40 = = 35 24 20 M5THRU` (04 NOS.) 45 F I N A L

- 53. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.45 BEARING MIDDLE SPACER 0.03 kg M.S PLATING 3/11/21 3/11/21 3/11/21 2 : 1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg - R.K A.M ECTI A A SECTION A-A 38 O 30 +0.2 +0.1 O 10 ±0.1 0.5 x 45° CH. (TYP.) A i 0.1 A F I N A L

- 54. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.46 LIMIT SW MOUNTING PLATE 0.22 kg M.S PLATING 10/11/21 10/11/21 - 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg 10/11/21 A.M R,K ECTI 75 60 = = 40 20 24±0.1 = = 30 = = 10 2 x 45° CHF' TYP. M5THRU' (04 NOS.) O6 THRU' C`BORE O10x6 DEEP (02 NOS) F I N A L

- 55. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.47 FRONT WHEEL SIDE SPACER 0.03 kg M.S PLATING 02/11/21 02/11/21 - 2 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg 02/11/21 R.K A.M ECTI A A SECTION A-A 40 O 30 +0.2 +0.1 O 6 ±0.1 0.5 x 45° CHF' (TYP.) A i 0.1 A F I N A L

- 56. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.48 REAR WHEEL SIDE SPACER 0.01 kg M.S PLATING 02/11/21 02/11/21 - 2 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg 02/11/21 R.K A.M ECTI A A SECTION A-A 40 O 30 +0.2 +0.1 O 2 ±0.1 0.5 x 45° CHF' (TYP.) A i 0.2 A F I N A L

- 57. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.49 SENSOR MTG. BRACKET 0.29 kg M.S PLATING 10/11/21 10/11/21 - 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg 10/11/21 A.M R,K ECTI - 40 120 15 24 = = 6 120 R 5 (TYP.) 15 50 O 19 O7THRU` (02 NOS.) 5 x 45° CHF' (TYP.) 26 50 UNFOLDING VIEW 40 26 45 BENDING LINES 56 32 F I N A L

- 58. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.50 DOG 0.19 kg M.S PAINTING 10/11/21 10/11/21 - 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg 10/11/21 A.M R.K ECTI 30 6 9 28 = = 45 R 3 TYP. 90 5 30 5 x 45° TYP. R 5 6 = = UNFOLDING VIEW 25 110 45 BENDING LENGHT 25 F I N A L

- 59. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.51 RAIL-2 12.43 kg M.S PAINTING 02/10/21 02/10/21 - 1 :5 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg 02/10/21 A.M R.K ( ) ~ ECTI 40 (TYP.) 1500±0.5 92 700 (TYP.) 32 32 Sr. No. DESCRIPTION SIZE QTY. REMARK 1 SQ.ROAD 32 X 32 X1500L 01 2 PLATE 60 X 40 X 8THK. 03 NOTES :- 1. ALL JOINTS TO BE FULL WELDED FILLET 5 mm. 2. EDGE PREPARATION TO BE DONE WHEREVER REQUIRED. 92 8 30 A DETAIL A 20 60 40 O18THRU` (03 NOS.) F I N A L

- 60. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.52 MOTOR MTG. PLATE 14.49 kg M.S PLATING 16/11/21 16/11/21 16/11/21 1 : 5 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg - R.K A.M ( ) ~ ECTI - 390 ±0.5 594±0.5 366 ±0.1 (TYP.) 540±0.2 = = (TYP.) 8 5 x 45° CHF' (TYP.) O7X 50.8 DEEP C`BORE 13x1 DEEP (06 NOS.) F I N A L

- 61. ALL DIMN.ARE IN MM IF IN DOUBT, ASK F 8 E D 7 6 5 C B A 8 7 6 5 4 3 2 1 F E D 4 3 2 C B 1 A HL055.01.53 POWER PACK TANK 22.81 kg M.S PAINTING 16/11/21 16/11/21 - 1 :5 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A2 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg 16/11/21 A.M R.K ( ) ~ ECTI - A A SECTION A-A 375 = = 75 (TYP.) 150 25 606 444 ±0.2 = = 366 ±0.2 = = 400±0.2 = = 50 TYP. 500 = = 500 = = 185 8 400 = = 540±0.2 = = 5 x 45° CHF' (TYP.) O9THRU` (08 NOS.) OM6THRU` (06 NOS.) 1 2 3 4 5 UNFOLDING VIEW 759 394 600 193 Sr. No. DESCRIPTION SIZE QTY. REMARK 1 PAD 500 X 75 X 8THK. 02 2 ISA 01 25 X25 X5THK. X600L 02 3 ISA 02 25 X 25 X5THK. X400L 02 4 SHEET 01 400 X 185 X3THK. 02 5 SHEET 02 760 X 600 X3THK. 01 3 NOTE :- 1. ALL JOINTS TO BE CO2 MIG WELDED. F I N A L

- 62. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.54 REAR PIVOT PIN BUSH 0.04 kg M.S PLATING 21.11.21 21.11.21 21.11.21 2 : 1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg - R.K A.M ( ) ECTI A A SECTION A-A 16 ±0.2 32 H7 O 38 g6 O 0.5 x 45° CH. (TYP.) A a 0.1 A F I N A L

- 63. A 1 C B 2 3 4 E D F 1 2 3 4 5 6 7 8 A B C IF IN DOUBT, ASK ALL DIMN.ARE IN MM 5 6 7 D E 8 F HL055.01.55 TIE BRACKET. 2.44 kg M.S PLATING 5/12/21 5/12/21 5/12/21 1 : 2 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A3 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg - R.K A.M ( ) ECTI - 50 = = 95 72 ±0.2 = = 5 x 45° CHF' (TYP.) 564 -0.3 -0.5 = = 548 8 O11THRU` (04 NOS.) Sr. No. DESCRIPTION SIZE QTY. REMARK 1 SQ. TUBE SQ.40X40X 4THK.X 548L 01 2 PLATE 95 x 50 x 8 THK. 02 NOTES :- 1. ALL JOINTS TO BE FULL WELDED FILLET 5 mm. 2. EDGE PREPARATION TO BE DONE WHEREVER REQUIRED. 40 = = F I N A L

- 64. A 1 C B 2 3 4 E D F 1 2 3 4 5 6 7 8 A B C IF IN DOUBT, ASK ALL DIMN.ARE IN MM 5 6 7 D E 8 F HL055.01.56 TIE BRACKET-2 2.61 kg M.S PLATING 5/12/21 5/12/21 5/12/21 1: 2 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A3 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg - R.K A.M ( ) ECTI - 50 = = 95 72 ±0.2 = = 5 x 45° CHF' (TYP.) O11THRU` (04 NOS.) 8 614 -0.3 -0.5 598 Sr. No. DESCRIPTION SIZE QTY. REMARK 1 SQ. TUBE SQ. 40X40 X 4 THK. x 598 L 01 2 PLATE 95 x 50 x 8 THK. 02 NOTES :- 1. ALL JOINTS TO BE FULL WELDED FILLET 5 mm. 2. EDGE PREPARATION TO BE DONE WHEREVER REQUIRED. 40 = = 1 2 F I N A L

- 65. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.57 ANTI BACK STOPPER 0.35 kg M.S PLATING A.M 27/12/21 27/12/21 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg 27/12/21 - R.K ECTI 40 90 20 = = 32 32 40 12 16 25 2 x 45° CH. TYP. O 18 H7THRU' 10 x 45° CH. TYP. R 2 5 R 12 R 20 F I N A L

- 66. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.58.REV.01 ANTI BACK STOPPER MOUNT 0.68 kg M.S PLATING 31/12/21 31/12/21 - 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg ( ) 31/12/21 R.K ECTI A.M 80 45 +0.2 +0.1 73 32 = = 66 = = 18 g6 O 8 50 = = 2 x 45° CH. TYP. 50 R 1 M8X 16 DEEP M12X 16 DEEP 17 34 = = O9THRU` (04 NOS.) O10H7 X 12 DEEP (04 NOS.) 28 15 1 F I N A L

- 67. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.59 STOPPER BACK PLATE 0.38 kg M.S PLATING 31/12/21 31/12/21 31/12/21 1 : 1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg - R.K A.M ECTI 22 72 R 15 R 5 5 5 ° 2 x 45° CH. TYP. 28 32 57.5 ±0.1 14 29 O14THRU` 50 F I N A L

- 68. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.60 ANTI BACK STOPPER RETAINER 0.02 kg M.S PLATING 27/12/21 27/12/21 - 2 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg 27/12/21 R.K ECTI A.M 25 O 6 O9THRU` CSK O17X90° 0.5 x 45° CH. (TYP.) F I N A L

- 69. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.61 BRASS SPACER 0.02 kg BRASS PLATING 27/12/21 27/12/21 27/12/21 2 : 1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg - R.K A.M ECTI A A SECTION A-A 4 ±0.1 35 O 18 +0.2 +0.1 O 0.5 x 45° CH. (TYP.) F I N A L

- 70. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.62 SPIRAL SPRING 0.01 kg SPRING STEEL -- 27/12/21 27/12/21 - 2 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg 27/12/21 R.K ECTI A.M 14 9 0 ° O 22 43 2 O 30 30 30 43 MINIMUM SPRING FORCE=3 KG MAXIMUM SPRING FORCE=8 KG COIL I.D. =22 MM. MATERIAL = SPRING STEEL ANGLE IN PRE-LOADED CONDITION PRE-LOADED FORCE =3 KG F I N A L

- 71. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.63 ANTI BACK STOPPER PIN 0.06 kg EN-8 PLATING 31/12/21 31/12/21 - 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg ( ) 31/12/21 A.M R.K ECTI - 20 O 16 = A/F= 10 23 +0.2 +0.1 48 ±0.1 14 g6 O 1 x 45° CH. TYP. NOTE :- TO BE HARDEN TO 28~30 HRc. 12 M F I N A L

- 72. IF IN DOUBT, ASK ALL DIMN.ARE IN MM HL055.01.64 ANTI BACK STOPPER IOCK UNLOCK PLATE 0.37 kg EN-8 PLATING 31/12/21 31/12/21 31/12/21 1 : 1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A4 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg - R.K A.M ECTI 22 72 R 15 R 5 5 5 ° 2 x 45° CH. TYP. 28 32 57.5 ±0.1 14 29 O14H7 THRU` 50 12 10 M8THRU` NOTE :- TO BE HARDEN TO 28~30 HRc. F I N A L

- 73. A 1 B C D 2 3 4 5 E F G H I 1 2 3 4 5 6 7 8 9 10 11 12 A B C D 6 7 8 9 10 E F G IF IN DOUBT, ASK ALL DIMN.ARE IN MM 11 12 H I HL055.02.00.01 SCISSOR LIFT-1 0.00 kg 16.11.21 16.11.21 16.11.21 1 :1 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A1 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg A.M ECTI R.K SR. NO. ITEM CODE DESCRIPTION QTY 1 6208-ZZ 4 2 PARALLEL KEY-8x7x124L 1 3 HYDRAULIC CYLINDER BORE-63x STROKE =195, PIN CENTRE TO CENTRE 475MM 2 4 PARALLEL KEY-8x7x124L 2 5 - SENSOR LIMIT SWITCH NG1-VS-510L24 WITH LED 24 V DC. 1 6 - SENSOR LIMIT SWITCH NG1-VS-510L24 WITH LED 24 V DC. 1 7 -- ALLEN CAP SCREW M10x30Lg. 20 8 -- ALLN CSK M8x16( S .S ) 12 9 -- HEX BOLT M8x35 4 10 -- ALLAN CAP SCREW M8x20 28 11 -- ALLAN CAP SCREW M6x30 2 12 -- ALLEN CAP SCREW M8x35 2 13 -- LOCK NUT M8 4 14 -- ALLAN CAP SCREW M6x10L 8 15 -- ALLAN CAP SCREW M6x16 8 16 -- ALLAN CAP SCREW M5x10 4 17 -- ALLAN C'SUNK SCREW M6x16L 4 18 -- ALLEN CAP SCREW M8 x 45Lg. 18 19 -- BEARING DEEP GROOVE 6006ZZ 4 20 -- ALLEN C'SUNK SCREW M6x10Lg. 28 21 -- Allan Csk M8x20 24 22 -- CIRCLIP INTERNAL B-55 4 23 -- ALLAN CAP SCREW M5x40 8 24 -- ALLAN CAP SCREW M10x20 32 25 -- BALL BEARING 6005 4 26 -- INT. CIRCLIP B-47 4 27 -- ALLEN CAP SCREW M8x12 24 28 -- ALLAN C'SUNK SCREW M6x16L 62 29 -- BEARING SKF-6206 ZZ 4 30 -- PLAIN BEARING BUSH 4 31 1/2"-52 PITCHES - 660.4 LONG + 1 LINK DUPLEX CHAIN-1/2" 1 32 HL055.01.-34.REV 01 POWER PACK MOUNT 4 33 HL055.01.01 BOTTOM FRAME 1 34 HL055.01.02 BOTTOM RAIL 2 35 HL055.01.03 SCISSOR PLATE-1 2 36 HL055.01.04 SCISSOR PLATE-2 2 37 HL055.01.05 TOP FRAME 1 38 HL055.01.06 ROLLER 4 39 HL055.01.07 ROLLER PIN 4 40 HL055.01.08 ROLLER RETAINER 4 41 HL055.01.09 FIX PIVOT PIN 4 42 HL055.01.10 CENTER PIN 2 43 HL055.01.11 CENTER PIVOT RETAINER 6 44 HL055.01.12 BEARING BOSS 4 45 HL055.01.13 WHEEL BRACKET REAR SIDE 2 46 HL055.01.14 WHEEL PIN 2 47 HL055.01.15 DRIVEN WHEEL 2 48 HL055.01.16 WHEEL RETAINER 2 49 HL055.01.17 WHEEL SPACER 2 50 HL055.01.18 RAIL-1 2 51 HL055.01.20 WHEEL SHAFT 1 52 HL055.01.21 SPROCKET REWORK 2 53 HL055.01.22 FRONT PIVOT BRACKET 1 54 HL055.01.23 REAR PIVOT BRACKET 1 55 HL055.01.24 STOPPER 3 56 HL055.01.25 STOPPER PAD 4 57 HL055.01.26 WHEEL STOPPER 6 58 HL055.01.27 CENTER PIVOT SPACER 2 59 HL055.01.28 TOP RAIL 2 60 HL055.01.29 REAR PIVOT LOCATOR 2 61 HL055.01.30 CYLINDER TOP PIN 4 62 HL055.01.31 CYLINDER TOP SPACER 8 63 HL055.01.32 DRIVE MOUNTING PLATE 1 64 HL055.01.33 BRACKET 1 65 HL055.01.35 DRIVING WHEEL 2 66 HL055.01.36 ROLLER RETAINER-2 4 67 HL055.01.38 SPROCKET RETAINER 1 68 HL055.01.39 GEARBOX-SHAFT 1 69 HL055.01.40 G.B. SHAFT RETAINER 3 70 HL055.01.41 WHEEL BRACKET FRONT SIDE 2 71 HL055.01.42 FRONT WHEEL SPACER 4 72 HL055.01.43 SET COLLER 2 73 HL055.01.44 LIMIT SWITCH MTG.STOPPER 1 74 HL055.01.45 BEARING MIDDLE SPACER 2 75 HL055.01.46 LIMIT SW MOUNTING PLATE 2 76 HL055.01.47 FRONT WHEEL SIDE SPACER 2 77 HL055.01.48 REAR WHEEL SIDE SPACER 2 78 HL055.01.49 SENSOR MTG. BRACKET 4 79 HL055.01.50 DOG 1 80 HL055.01.51 RAIL-2 2 81 HL055.01.52 MOTOR MTG. PLATE 1 82 HL055.01.53 POWER PACK TANK 1 83 HL055.02.01 CHEQUARD PLATE 1 84 HL055.02.02 ISA50X50X5THK 2 85 W75 U100 P80 B5B3+BN80A4 GEARED MOTOR, 0.55 KW, O/P RPM=14 1 2000 800 C C A A SECTION A-A 34 33 31 35 36 37 46 45 46 47 48 49 50 51 56 73 59 60 63 64 32 65 83 69 70 71 72 85 3 5 4 22 19 17 29 D D SECTION D-D 6 80 57 55 9 13 14 7 23 24 28 76 77 74 20 35 73 56 9 13 17 63 10 20 60 21 45 54 54 78 SECTION C-C 1 58 44 43 42 8 1180 43 62 61 53 7 84 27 79 75 E E SECTION E-E 39 26 25 40 66 38 34 18 F F SECTION F-F 30 41 12 11 16 15 1180 4 68 2 69 52 3500 1750 780 56 E E 82 81 67 F I N A L

- 74. A 1 C B 2 3 4 E D F 1 2 3 4 5 6 7 8 A B C IF IN DOUBT, ASK ALL DIMN.ARE IN MM 5 6 7 D E 8 F HL055.02.02 ISA50X50X5THK 7.65 kg STD. PAINTING 11/11/21 11/11/21 - 1 :5 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A3 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. ( ) ~ Kg A.M R.K 11/11/21 ECTI - SIDE VIEW 50 50 25 6 1650±0.5 = = 150±0.2 (TYP.) O9THRU` (12 NOS.) 1750±0.5 50 50 6 R 6 R 5 (TYP.) USE STD. ANGLE-ISA50x50x5THK. F I N A L

- 75. A 1 B C D 2 3 4 5 E F G H I 1 2 3 4 5 6 7 8 9 10 11 12 A B C D 6 7 8 9 10 E F G IF IN DOUBT, ASK ALL DIMN.ARE IN MM 11 12 H I HYDROLINK-DAP00 SCISSOR LIFT-1 0.00 kg -- 27.09.21 27.09.21 27.09.21 1 : 10 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A1 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg ECTI A.M R.K - 1155 5 3 ° 1750 1620 3 3 ° 1013 G.L. 126 226 142 20 658 LIFT 497 CLOSING 2 8 ° 8° 500 800 92 400 362 300 812 800 POWER PACK TANK=100 LIT. GEARED MOTOR- AS SERIES -BONFIGLIOLI 0.55KW TECHNICAL SPECIFICATIONS- 1. CLOSING HEIGHT=500MM. 2. OPEN HEIGHT=1150MM. 3. LIFT=650MM. 4. LIFTING CAPACITY=1.5TON. 5. LINEAR TRAVEL SPEED=3 M/MIN. 924 = = HYDRAULIC CYLINER 63 BORE-2NOS NYLON PAD TOP POAITION SENSING LIMIT SWITCH 1404 F I N A L

- 76. A 1 B C D 2 3 4 5 E F G H I 1 2 3 4 5 6 7 8 9 10 11 12 A B C D 6 7 8 9 10 E F G IF IN DOUBT, ASK ALL DIMN.ARE IN MM 11 12 H I HYDROLINK-DAP00 SCISSOR LIFT-1 0.00 kg -- 27.09.21 27.09.21 27.09.21 1 : 10 MATERIAL:- MACHINING:- SURFACE FINISH:- FINISH PART WT.- SHEET SIZE:- A1 1 OF 1 01 SHEET DWG NO.: DRAWING NAME DATE DRN. REVISION DESCRIPTION No. PROPOSAL / ORDER NO. 8000 4000 4000 2000 2000 1000 1000 315 315 120 30 120 ±3 ±2 ±1.2 ±0.8 ±0.5 ±0.3 TOL. UPTO ABOVE UNSPECIFIED TOLERANCES DATE SIGN SCALE APPD. CHD. DRN. ALL DIMENSIONS ARE IN MM. Kg A.M R.K ECTI - 491 1750 1570 8° 349 G.L. 128 142 20 491.3 500 800 92 400 362 300 812 800 POWER PACK TANK=100 LIT. GEARED MOTOR- AS SERIES -BONFIGLIOLI 0.55KW TECHNICAL SPECIFICATIONS- 1. CLOSING HEIGHT=500MM. 2. OPEN HEIGHT=1150MM. 3. LIFT=650MM. 4. LIFTING CAPACITY=1.5TON. 5. LINEAR TRAVEL SPEED=3 M/MIN. 924 = = HYDRAULIC CYLINER 63 BORE-2NOS NYLON PAD TOP POAITION SENSING LIMIT SWITCH 1404 3 1 ° F I N A L