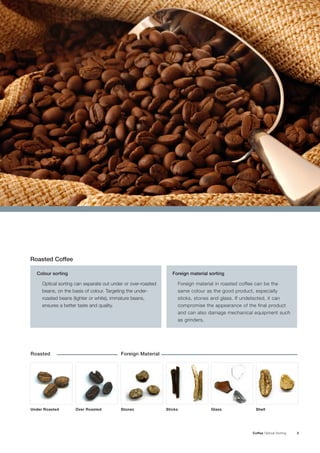

Bühler provides optical sorting solutions for coffee processors to precisely sort coffee beans and remove defects. Their sorting machines use advanced technologies like LED lighting, cameras, and shape detection to identify and separate beans by color, size, and foreign material. This helps processors improve quality and yield while reducing costs through increased efficiency and productivity. Bühler invests in R&D to develop sorting machines that can remove even very subtle defects from various types of green and roasted coffee beans.