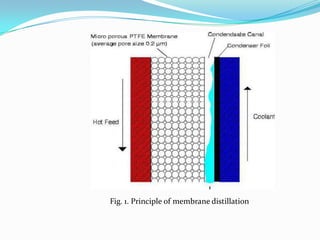

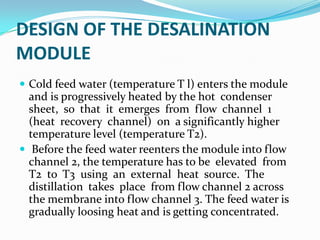

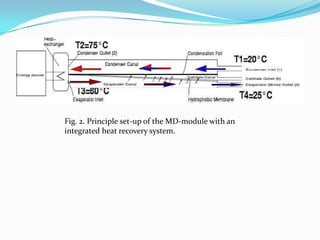

This document describes a solar powered desalination system using membrane distillation. Membrane distillation uses a hydrophobic membrane that allows water vapor to pass through but prevents liquid water from passing. A temperature difference across the membrane causes water to evaporate on the hot side and condense on the cold side, removing salt. The system uses spiral wound modules with an integrated heat recovery system to preheat feed water. It operates at low pressures and temperatures below 80°C, producing pure water for applications like boiler feed water without requiring chemical pretreatment or being susceptible to fouling. The technology has been optimized and is used in countries like Australia, the US and Germany.