As manufacturing grows more complex, smart IoT solutions are transforming how factories operate—boosting efficiency, cutting downtime, and solving critical challenges.

🚨 Dive into the blog to uncover:

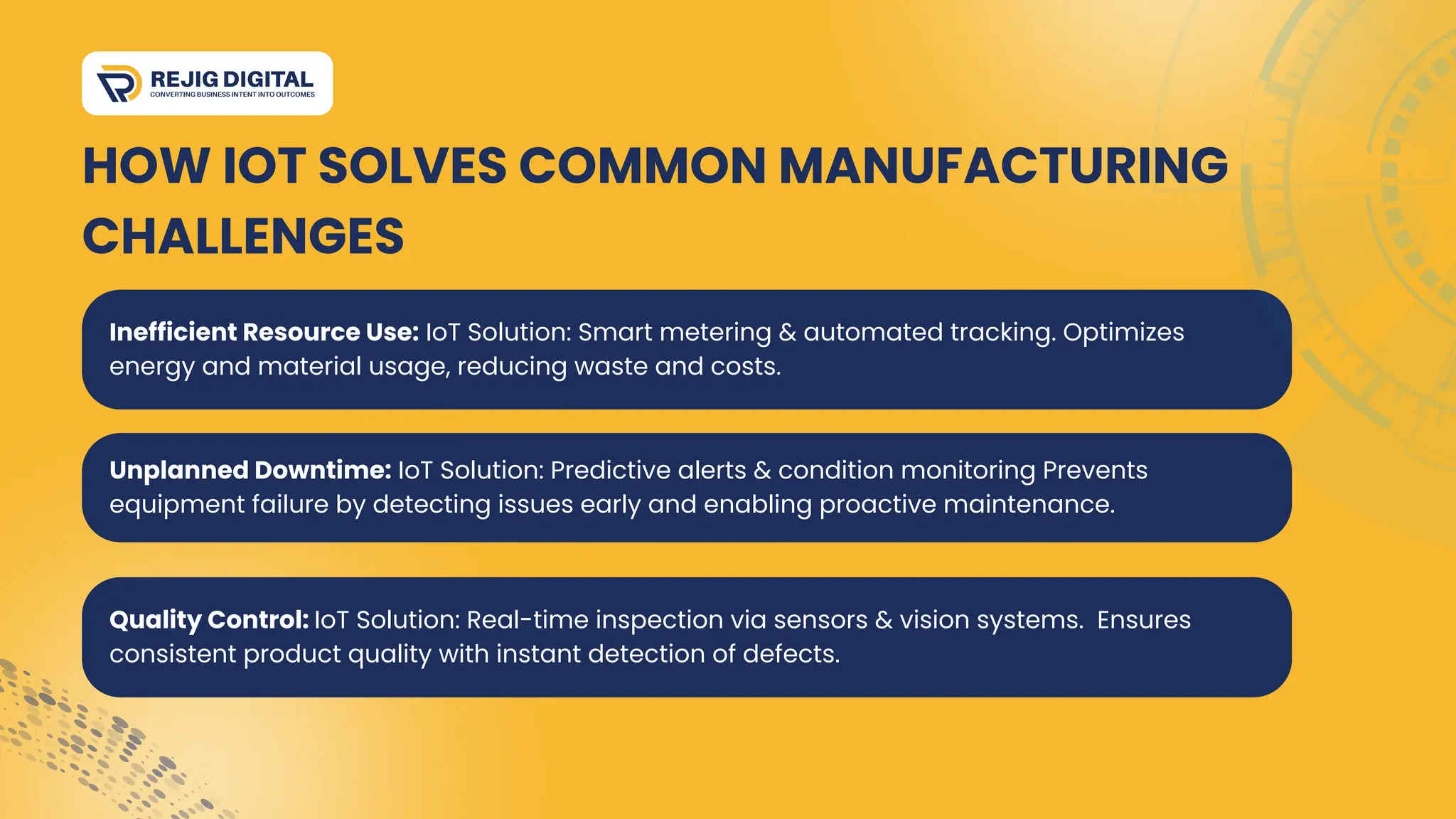

✅ How real-time monitoring improves decision-making and prevents disruptions

✅ Why predictive maintenance reduces unexpected equipment failure

✅ How automation accelerates production and ensures quality

✅ The impact of connected systems on energy use and resource savings

✅ Key strategies for integrating IoT across operations

📖 Read the full blog now: https://www.rejigdigital.com/blog/the-impact-of-iiot-on-the-manufacturing-sector/