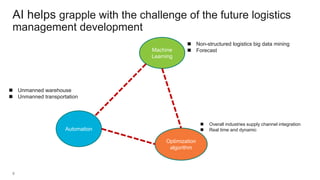

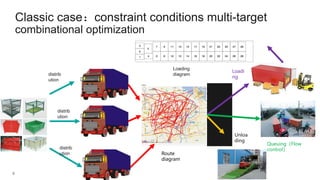

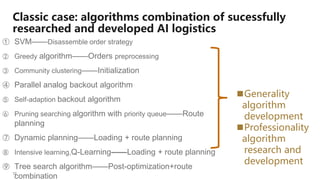

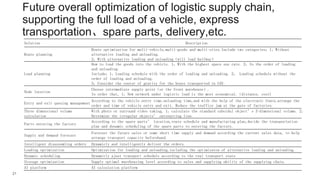

This document introduces a smart logistics project that uses artificial intelligence to optimize logistics operations. It discusses using AI for transportation strategy, warehousing strategy, network strategy, and dispatch control. The goal is to maximize service while minimizing costs under constraints. Example applications discussed include spare parts logistics transport optimization, constraint conditions multi-target optimization, and algorithms that were developed and combined successfully for AI logistics. The project aims to fully optimize supply chain logistics in the future using strong AI and brain-inspired intelligence.