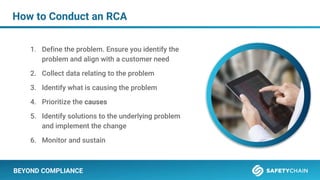

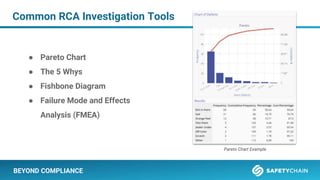

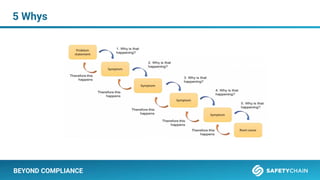

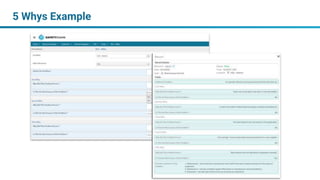

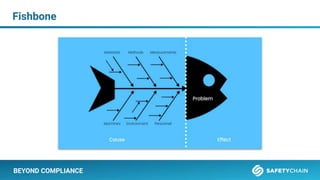

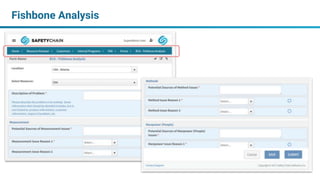

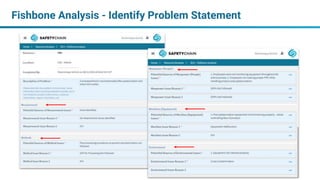

The document discusses a webinar and podcast series focused on root cause analysis (RCA) and corrective and preventive actions (CAPA) for food, beverage, and consumer packaged goods manufacturers. It outlines definitions, methodologies, and the significance of RCA and CAPA in improving quality and compliance, emphasizing their role in preventing future occurrences of problems. Various tools for conducting RCA, such as Pareto charts and the 5 Whys, are also highlighted.