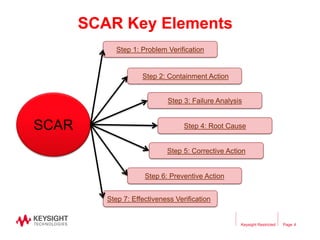

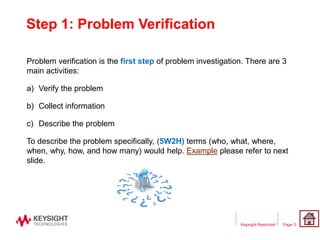

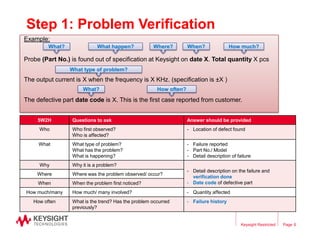

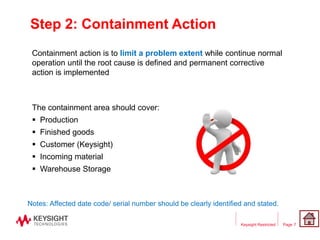

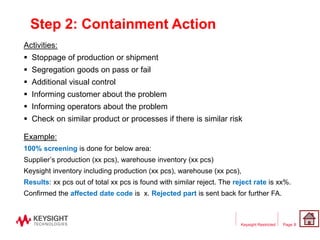

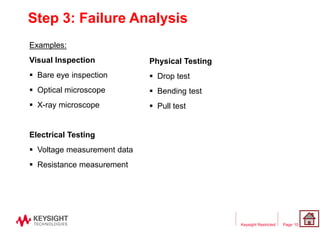

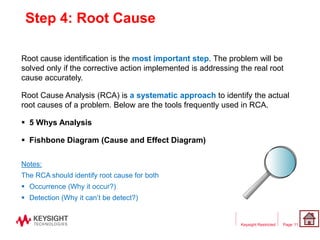

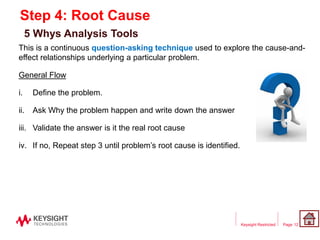

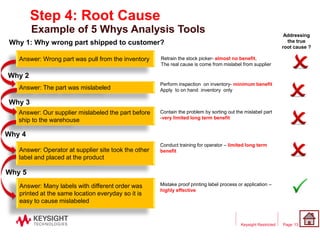

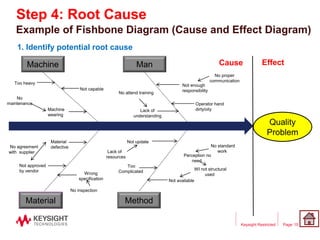

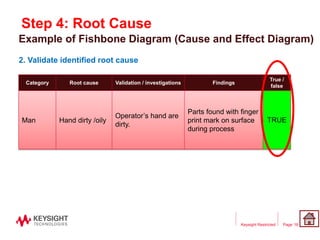

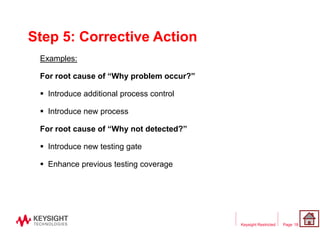

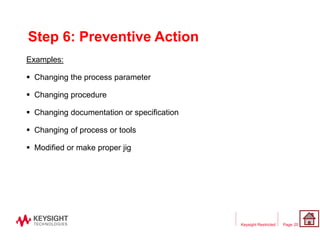

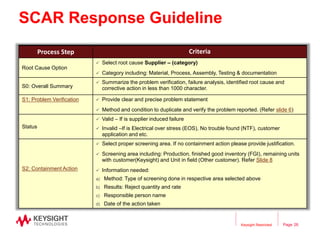

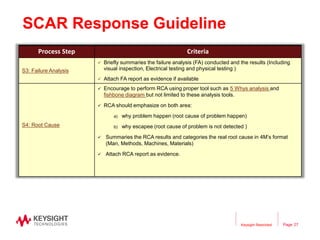

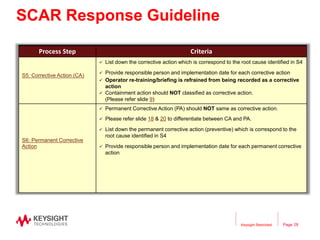

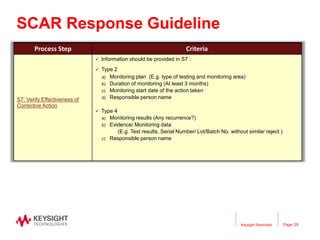

The document provides guidance on conducting a proper Root Cause Analysis (RCA) with a supplier using a Supplier Corrective Action Request (SCAR). It outlines the key elements of a SCAR, which includes 7 steps: 1) problem verification, 2) containment action, 3) failure analysis, 4) root cause analysis, 5) corrective action, 6) preventive action, and 7) effectiveness verification. Examples are provided for each step to illustrate the process. The document emphasizes that identifying the true root cause is critical and recommends tools like 5 Whys analysis and fishbone diagrams to aid in root cause analysis. It also stresses that corrective and preventive actions should correspond to the identified root cause to prevent recurrence.