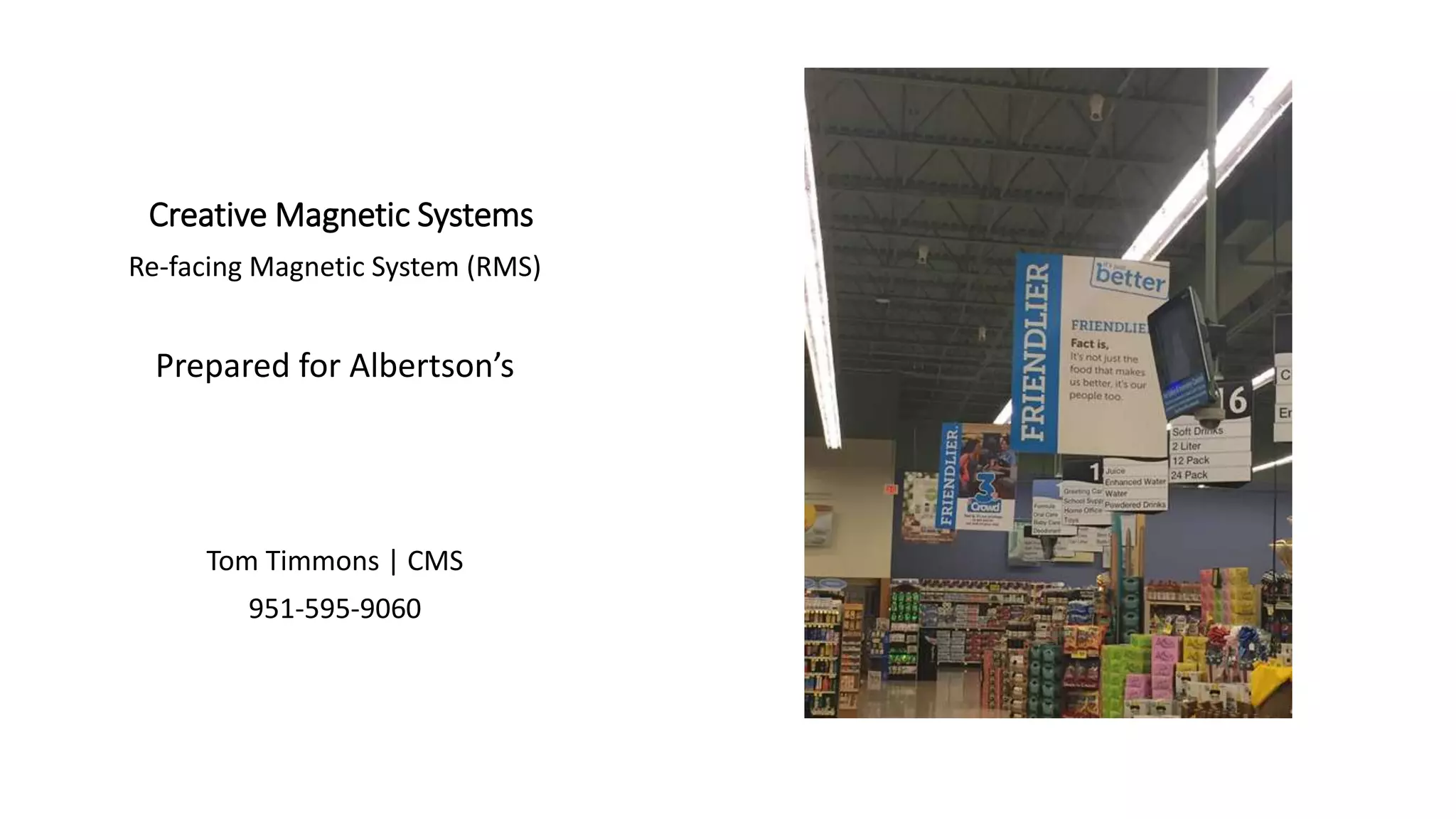

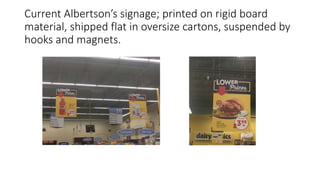

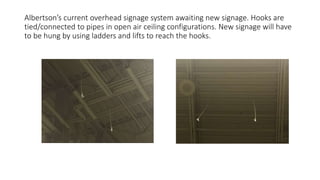

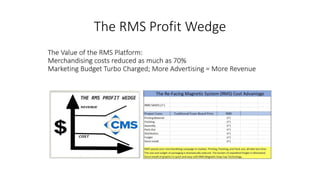

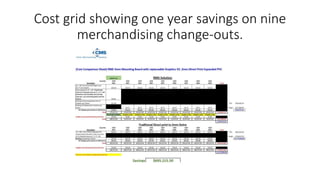

The document presents the Re-Facing Magnetic System (RMS) developed for Albertson's to address in-store signage issues, which has been successfully tested for over a decade. RMS eliminates the need for rigid board displays, significantly reducing shipping costs, labor, and installation time while enhancing safety by removing the necessity for ladders. Key benefits include multi-purpose utility, easy assembly, and substantial cost savings, with studies indicating 70%-90% savings on merchandising change-outs.