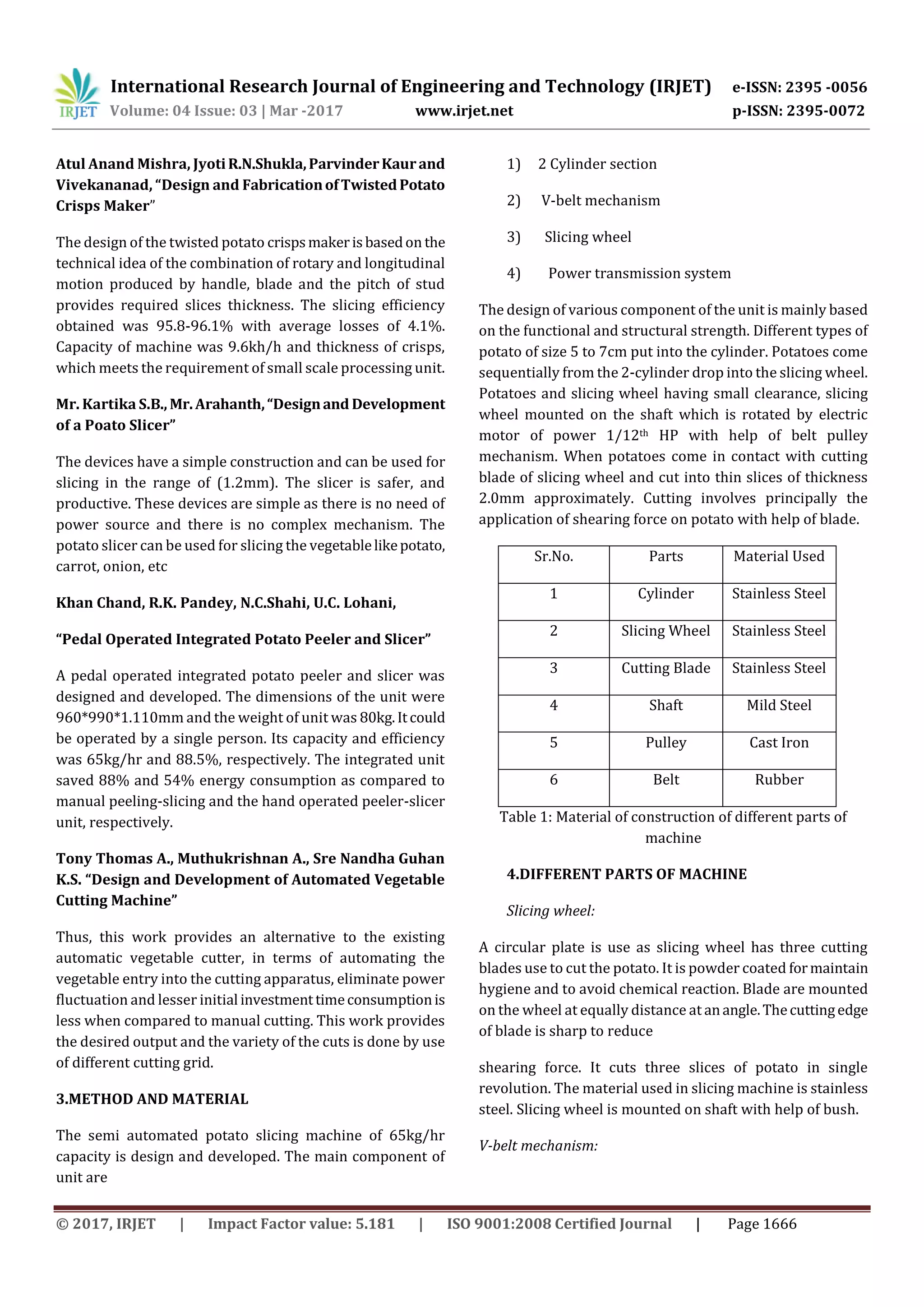

This document summarizes the design and development of a semi-automatic potato chips machine. The machine uses a slicing wheel with sharp blades powered by a 1/12 HP electric motor to cut potatoes into uniform 2mm thick slices at a rate of 60kg per hour. Potatoes are fed into two cylinders and drop onto the rotating slicing wheel to be cut. The key components are the slicing wheel, V-belt power transmission system, cylinders, and electric motor. The design aims to provide a low-cost, simple machine for small-scale potato chip production.