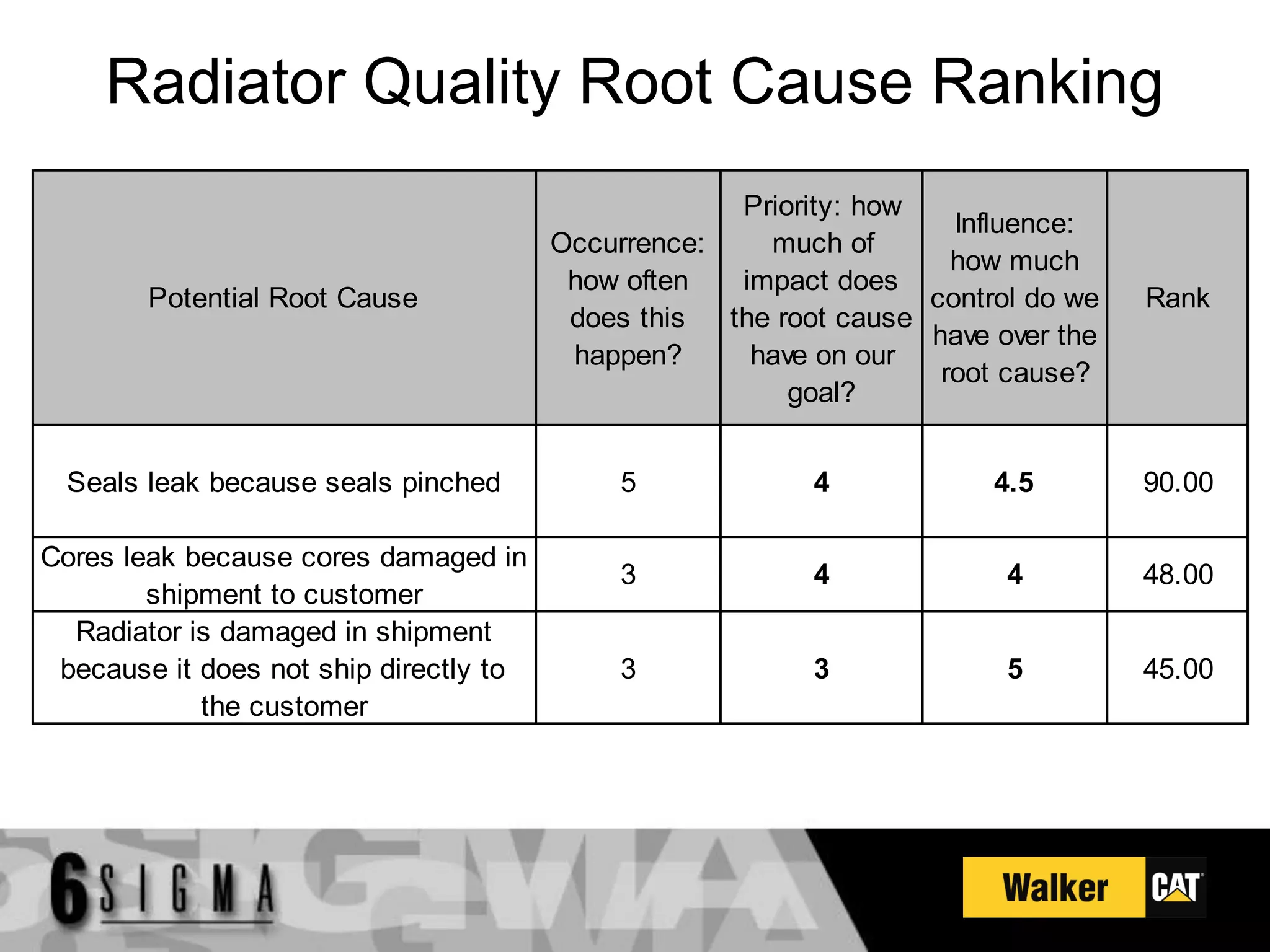

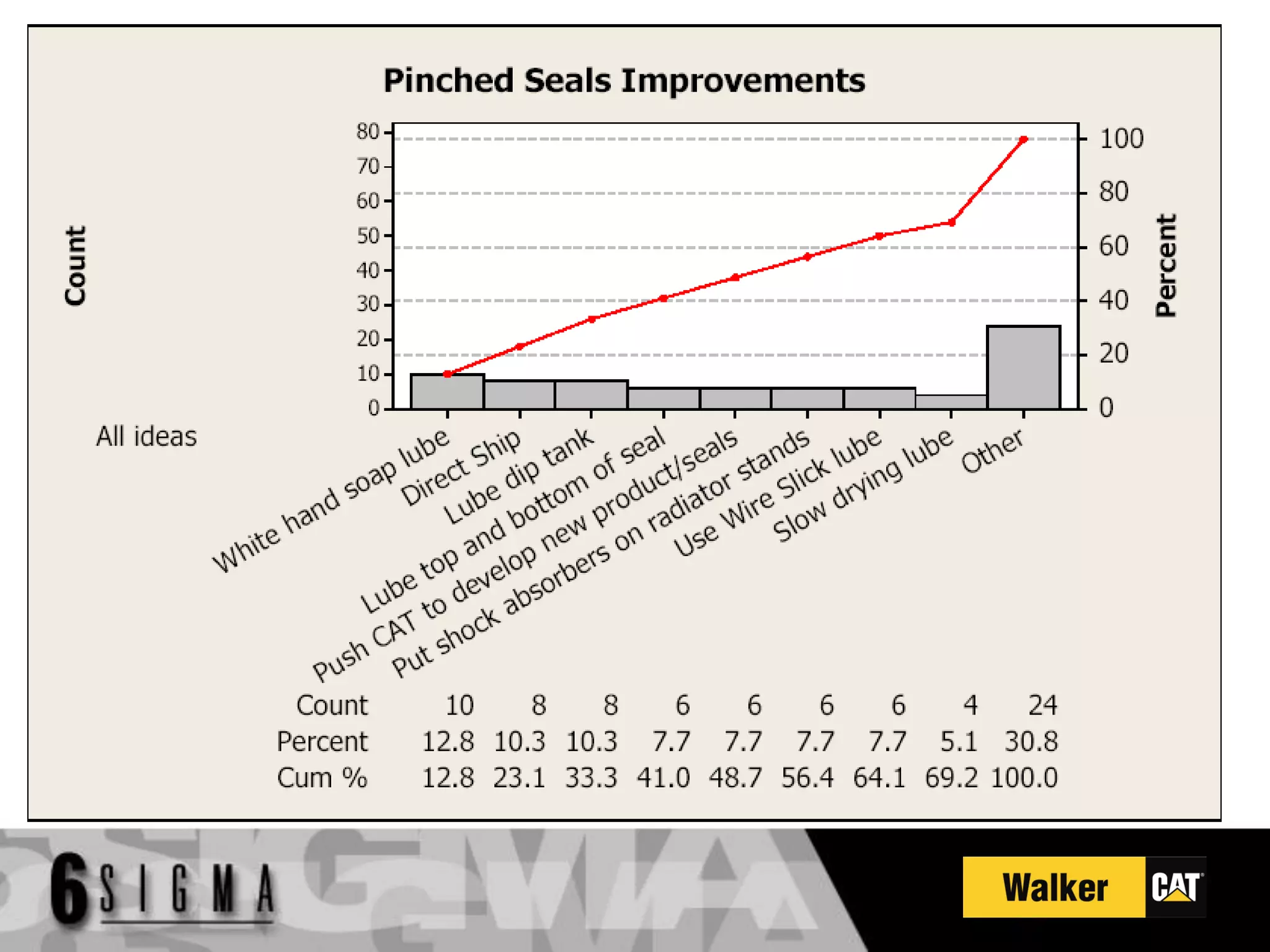

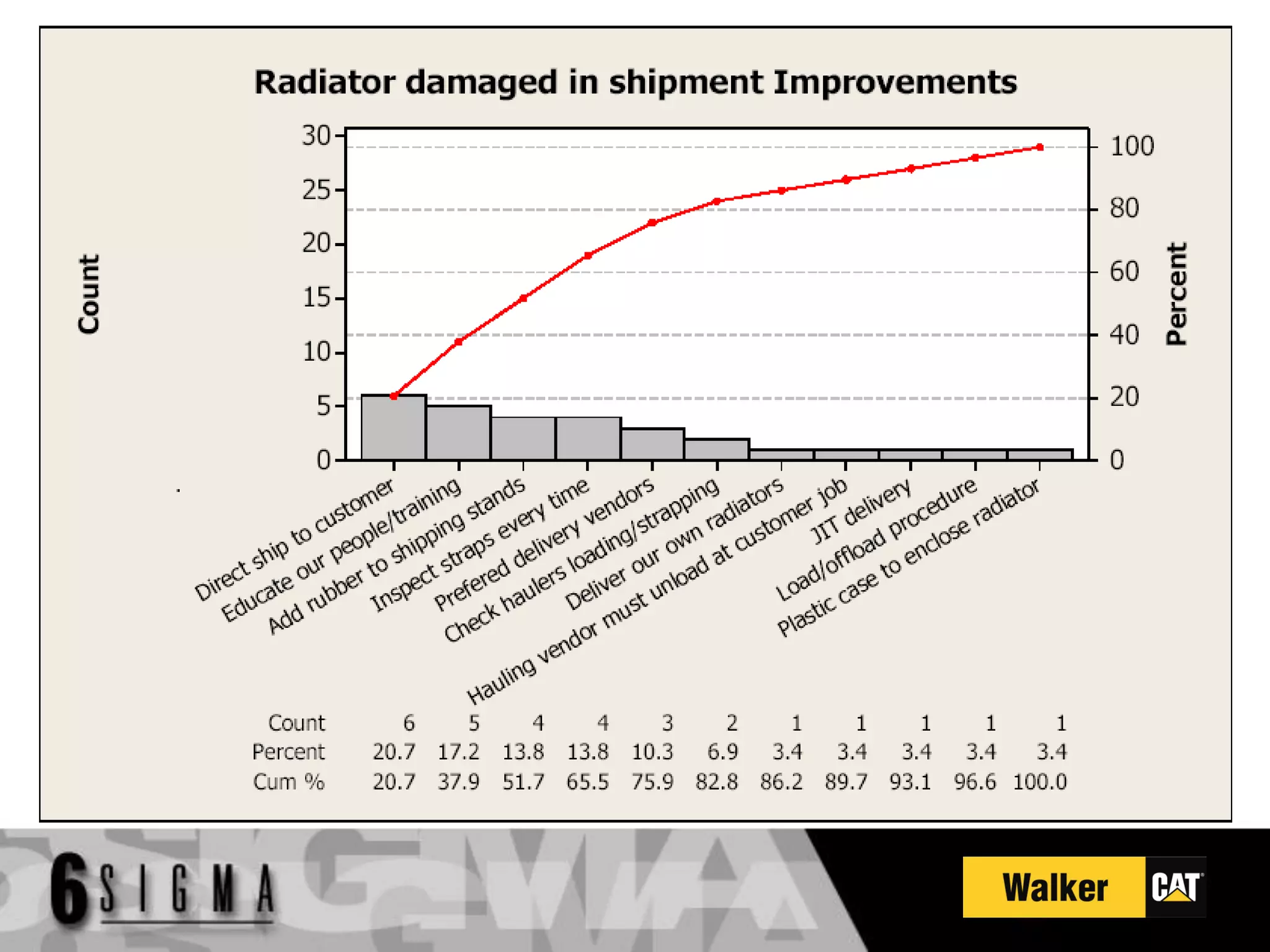

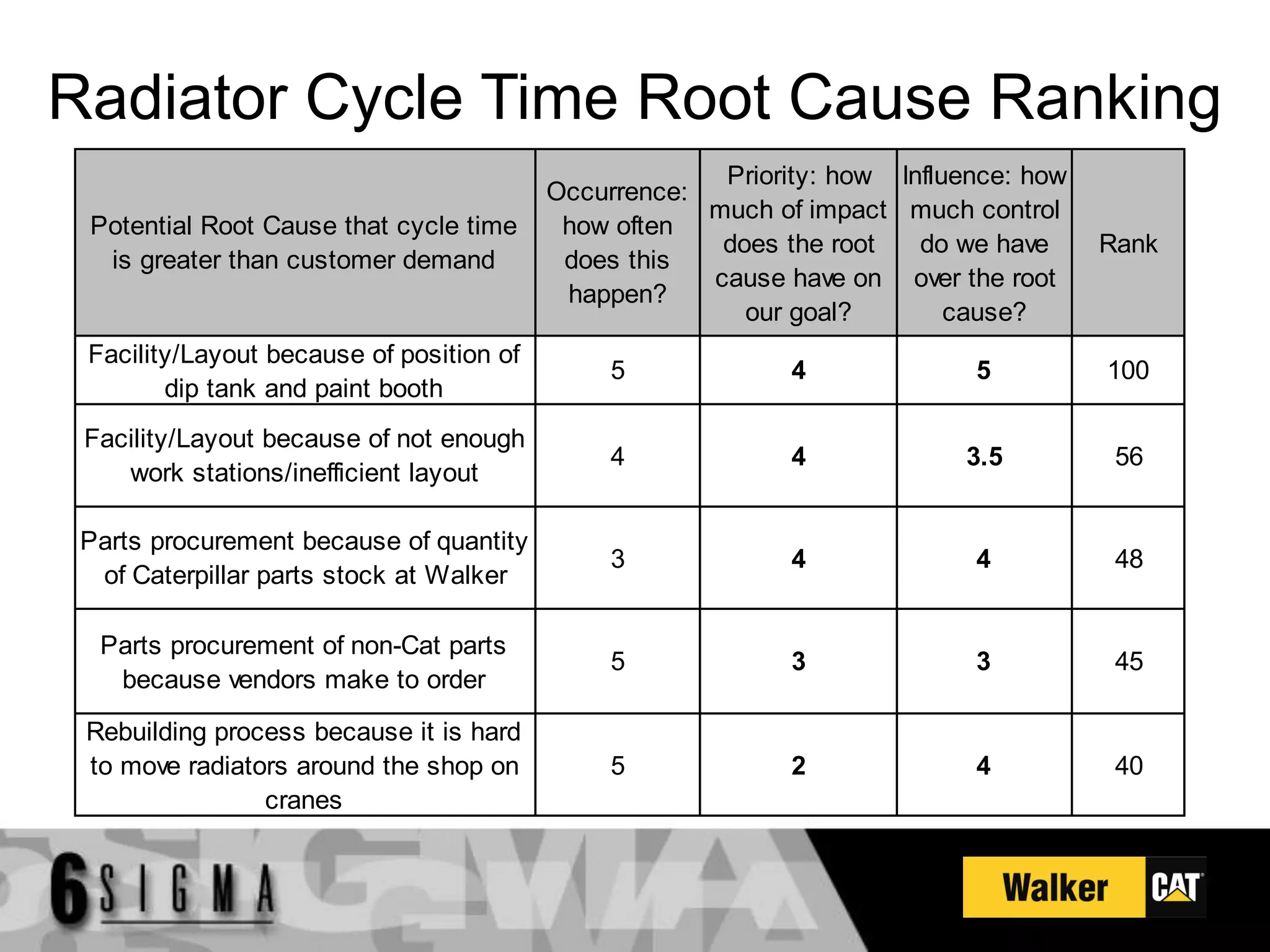

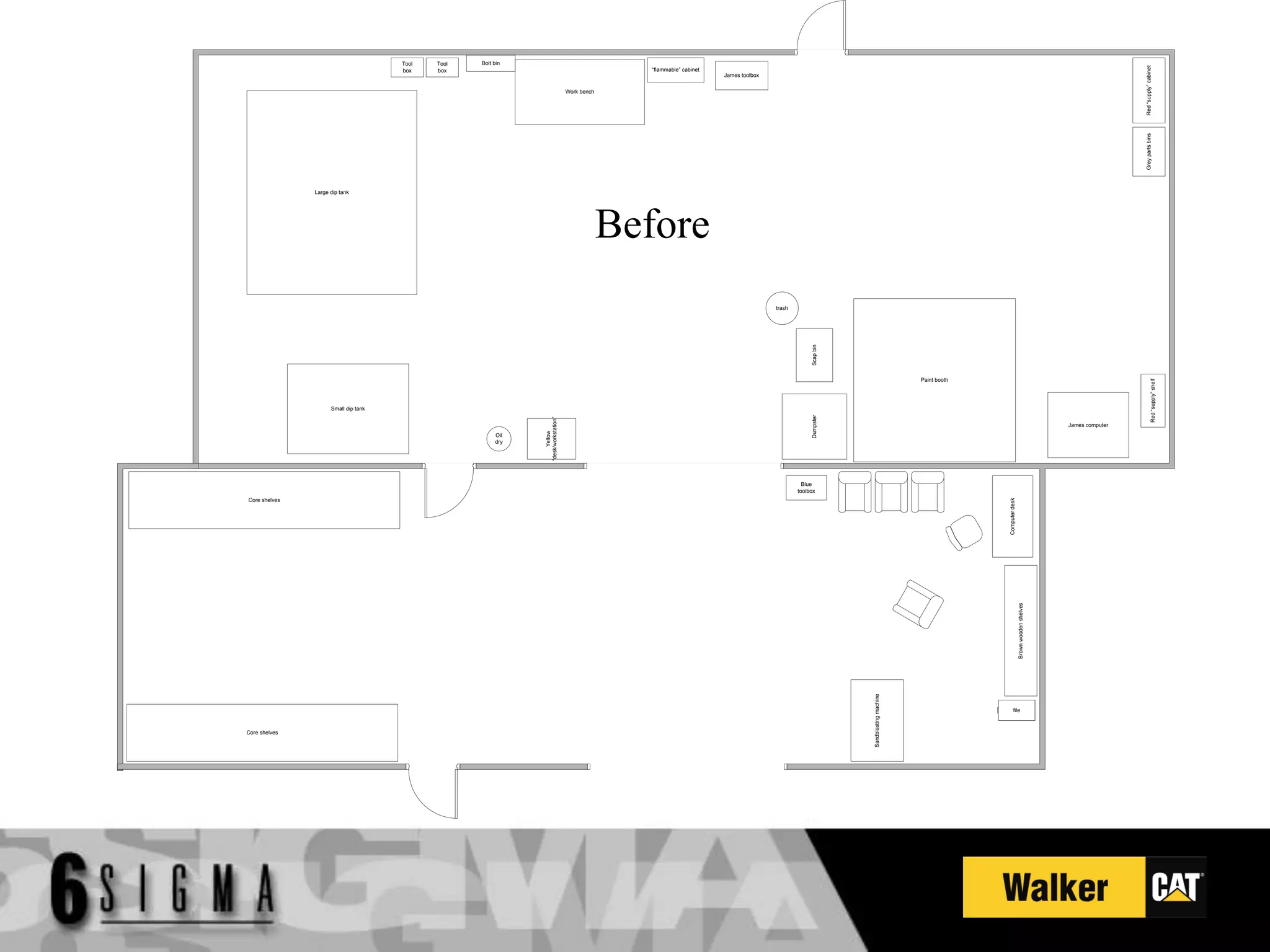

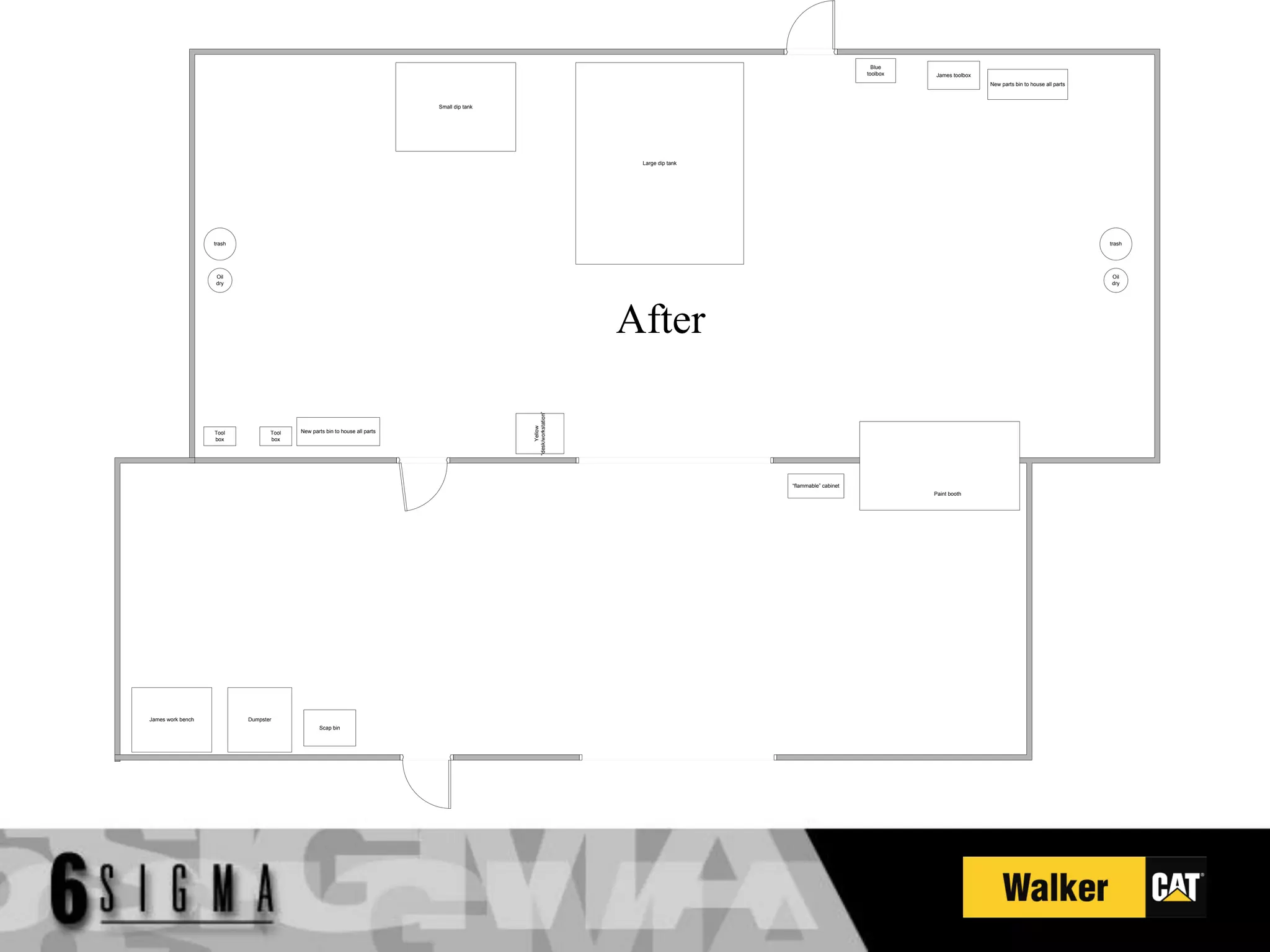

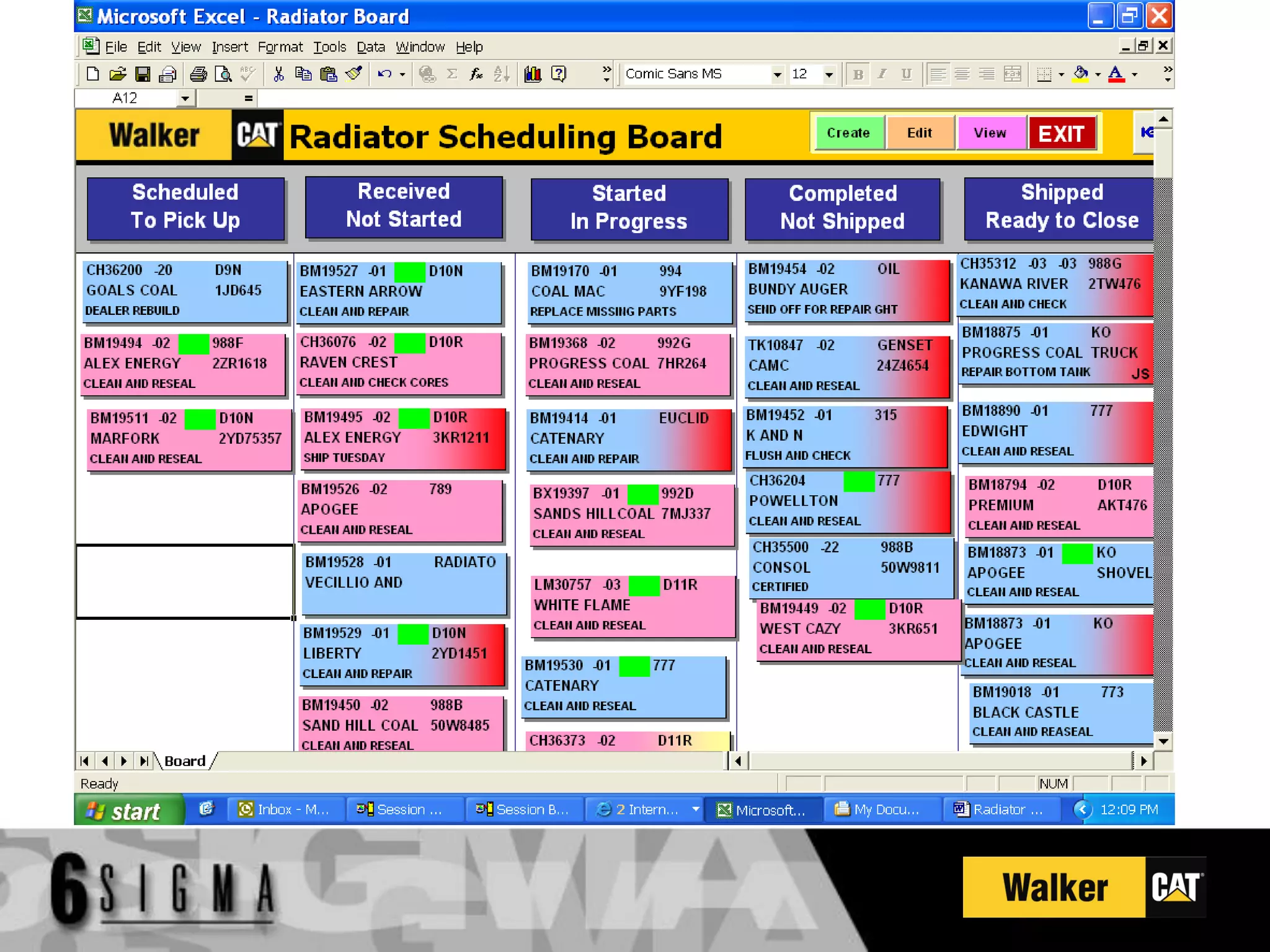

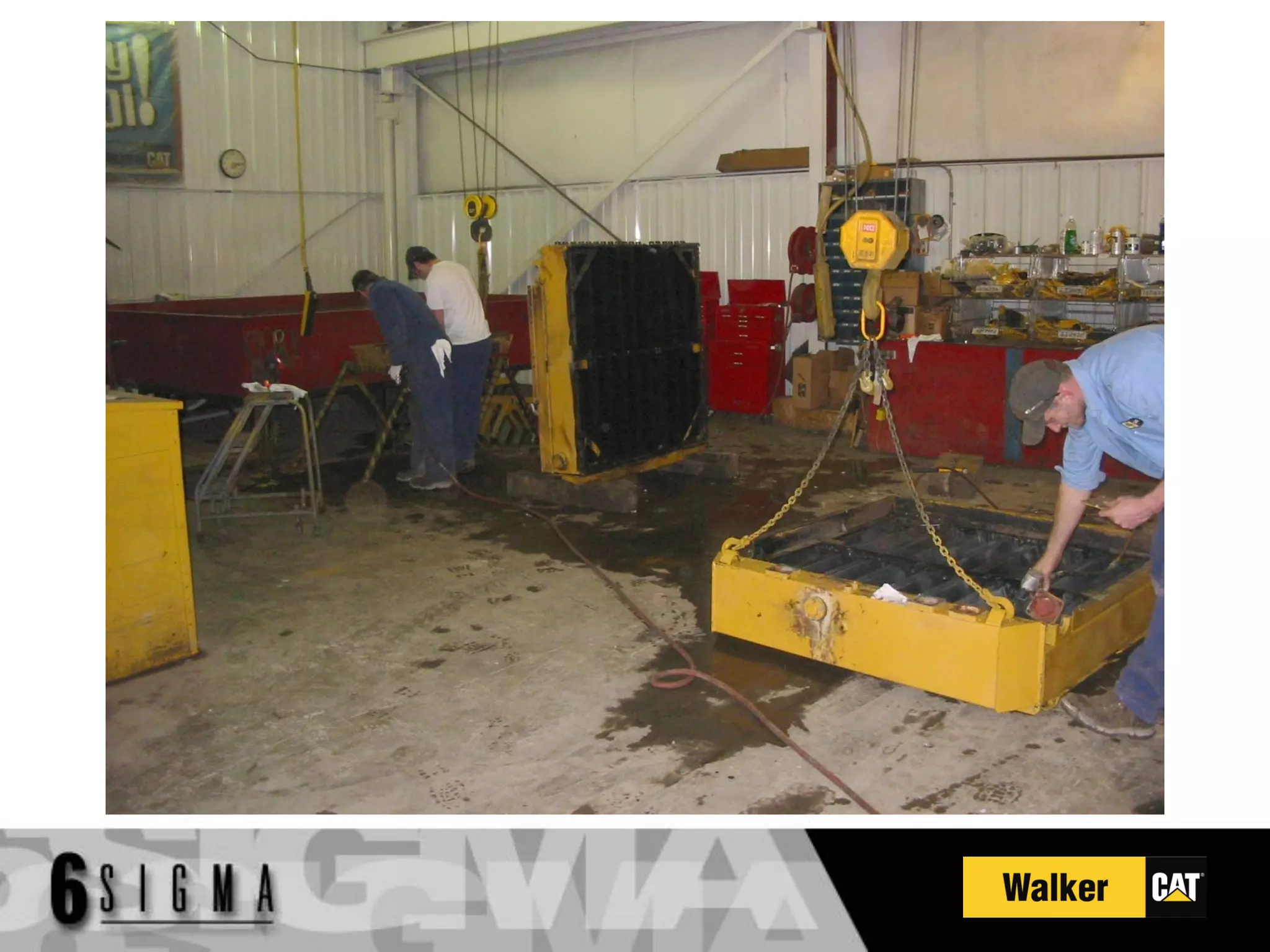

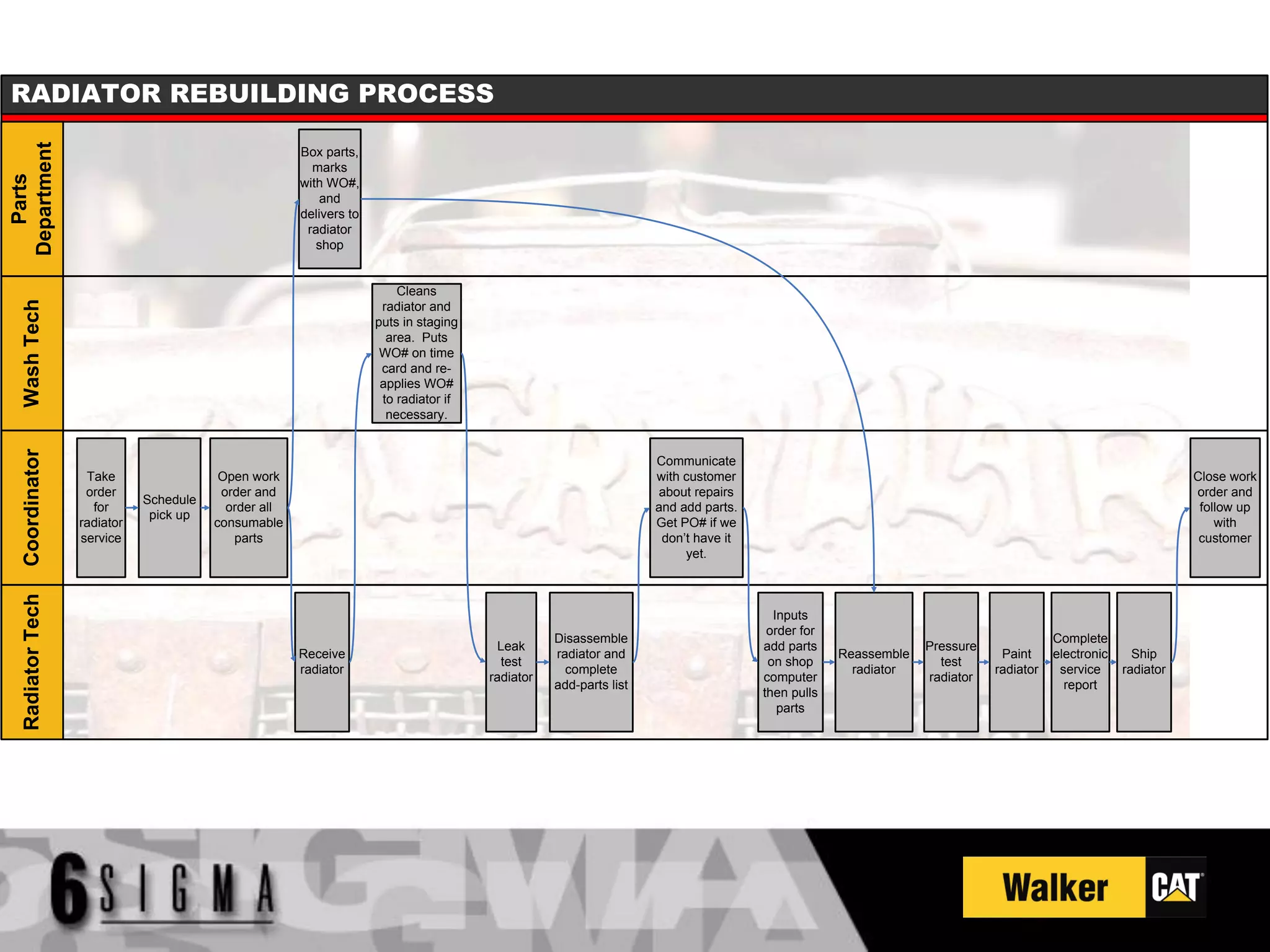

This document summarizes a radiator rebuild project at a company called Walker. It includes two root cause analyses, one for radiator quality issues and one for long cycle times. For quality issues, the top root cause was seals leaking due to being pinched, followed by cores leaking from damage in shipment. For cycle times, the top causes were the facility layout related to the dip tank and paint booth positions and not having enough work stations. The document also includes a process flow chart of the radiator rebuilding process from receiving parts to shipping the completed radiator.