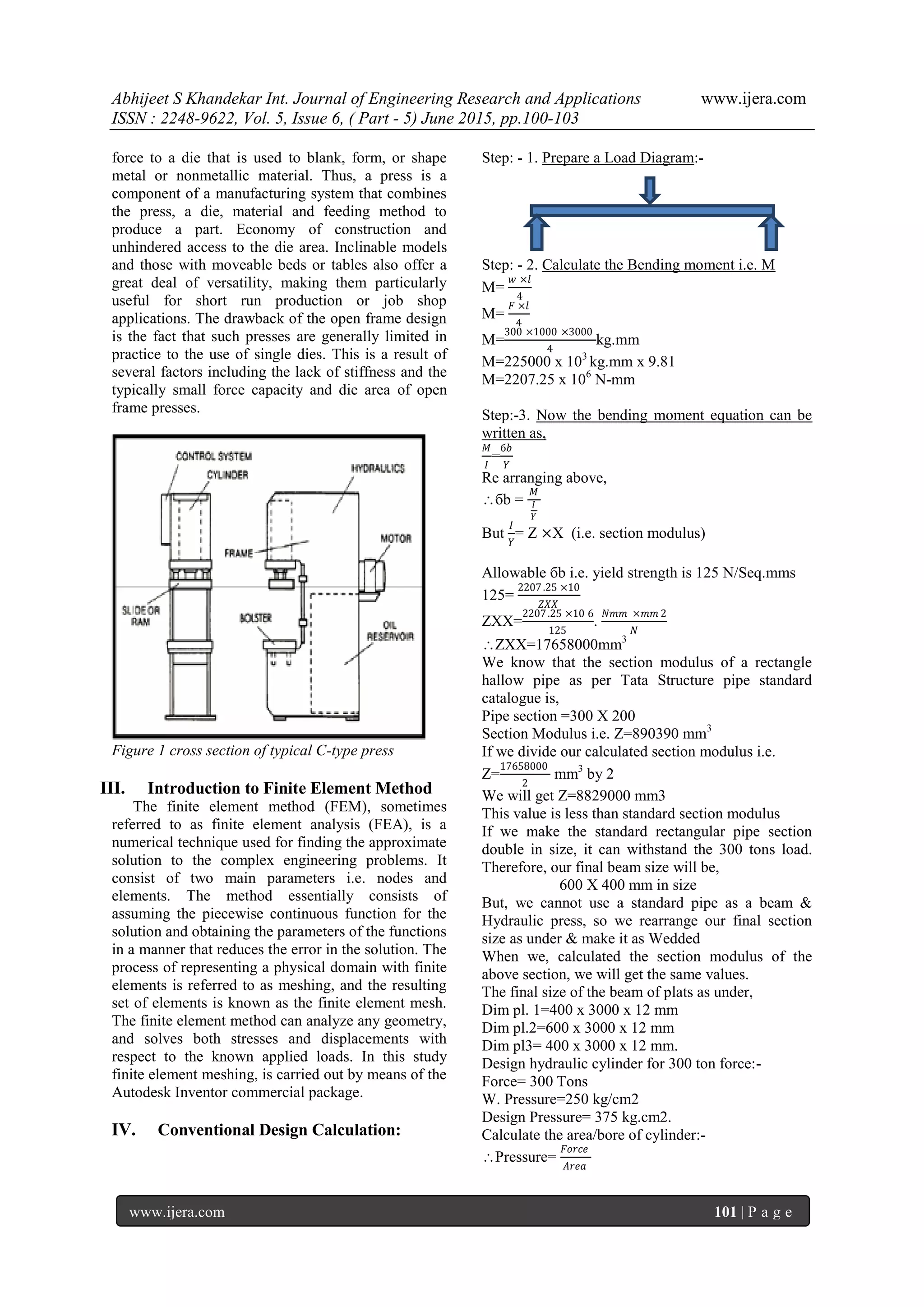

This document summarizes the design and 3D modeling of a heavy-duty hydraulic press with a 300-ton capacity. It first describes performing conventional design calculations to size the main structural components, including beams, hydraulic cylinder, end caps, and glands. Finite element analysis is then conducted on a 3D model of the press to optimize the design and validate the stress levels calculated through conventional methods. The summary concludes that the conventional calculations estimated a stress of 150 kg/cm2 in the cylinder mounting plate, and further finite element analysis will be used to optimize the design.

![Abhijeet S Khandekar Int. Journal of Engineering Research and Applications www.ijera.com

ISSN : 2248-9622, Vol. 5, Issue 6, ( Part - 5) June 2015, pp.100-103

www.ijera.com 103 | P a g e

V. Conclusion.

In this paper, conventional design calculation of

Metal Forming Heavy duty Hydraulic Presshas been

defined& 3D modeling of the press has been done.

Stress obtained by conventional design calculation is

б=150 kg/cm2

Further Finite element method will be

used to calculate design for the optimization.

References / Bibliography:

[1] IS 8064:2002, “Method of Designation of

Mechanical & Hydraulic Presses” published

by Bureau of Indian Standards, New Delhi,

April 2002.

[2] Muni Prabaharan and V.Amarnath, “Structural

Optimization of 5Ton Hydraulic Press and

Scrap Baling Press for Cost Reduction by

Topology”, International Journal of Modelling

and Optimization, Vol. 1, No. 3, August 2011.

[3] Zhicheng Huang, Nanxing Wu, Xingguo

Wang, “Contact Analysis on the Whole Frame

of 32.8MN PRESS”, TELKOMNIKA, Vol.

11, July 2013.

[4] H. N. Chauhan, M.P. Bambhani “Design &

Analysis of Frame of 63 Ton Power press

Machine by using Finite Element Method”,

Indian Journal of Applied Research,

Engineering, Volume-3, July 2013.

[5] B.N. Khicadia, D. M.Chauhan “A review on

Design & Analysis of Mechanical Press

Frame” -International Journal of Advance

Engineering and Research Development,

Volume 1, June 2014.](https://image.slidesharecdn.com/r5605100103-150802102753-lva1-app6891/75/Conventional-Design-Calculation-3D-Modeling-of-Metal-Forming-Heavy-duty-Hydraulic-Press-4-2048.jpg)