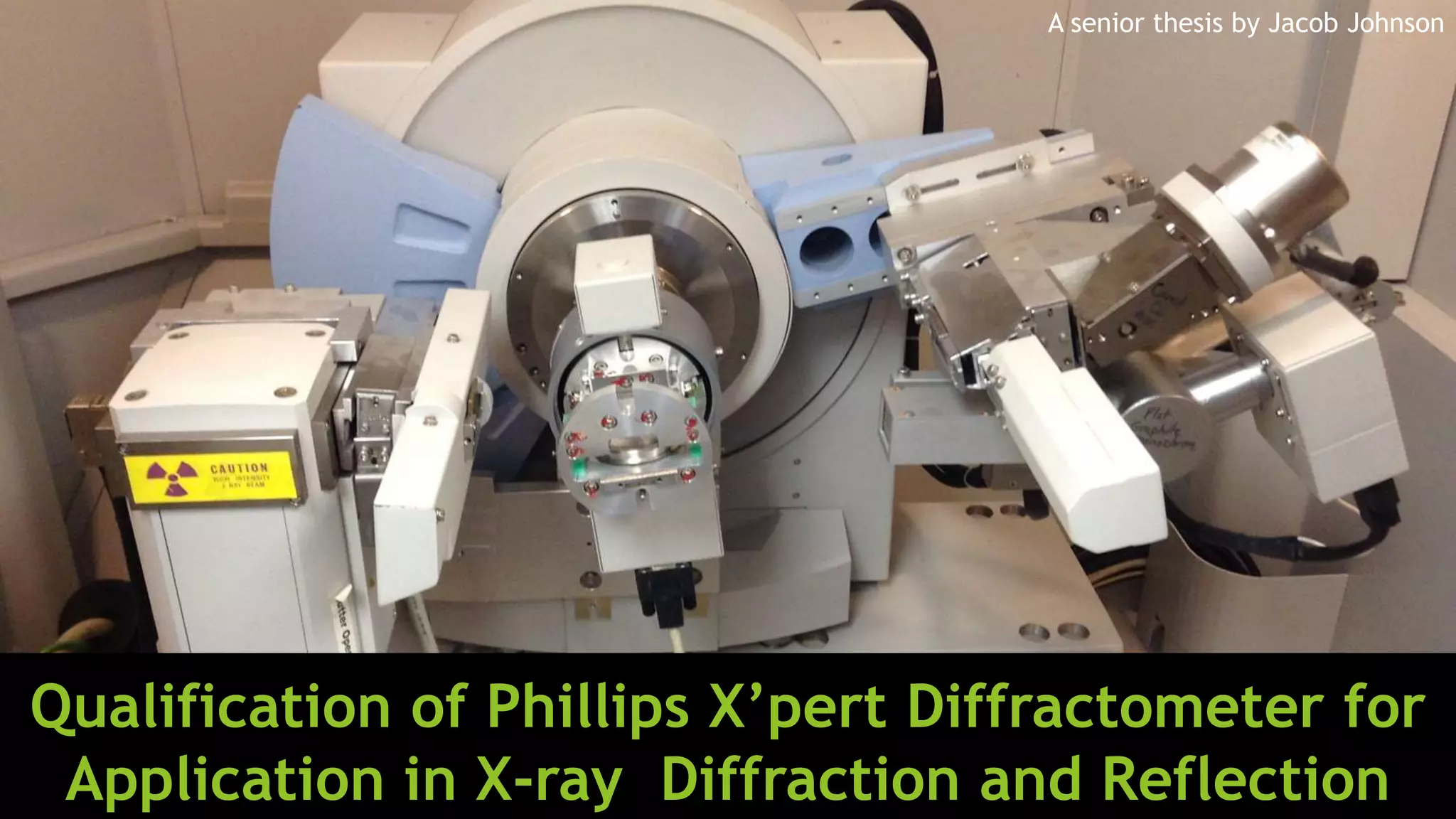

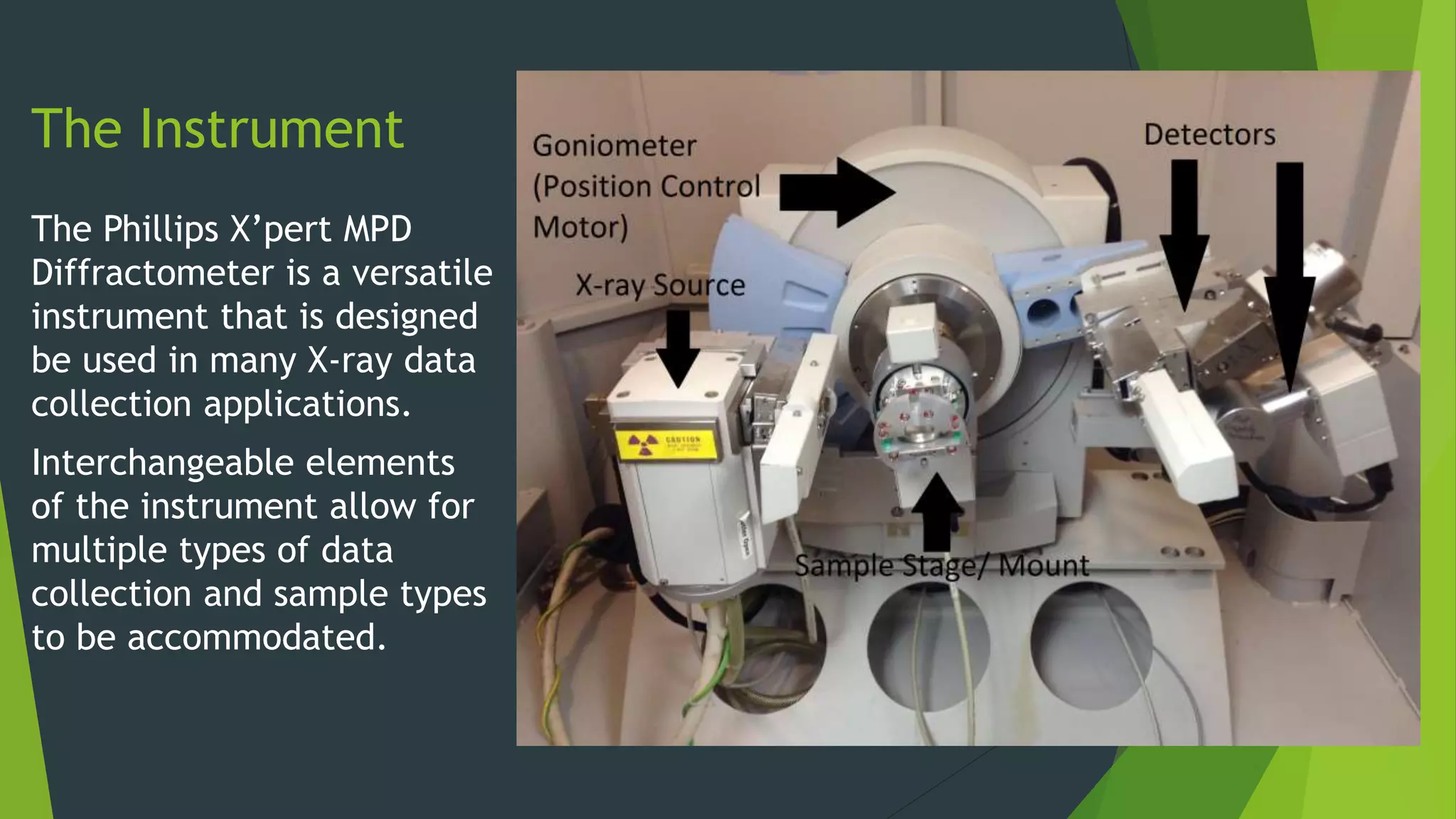

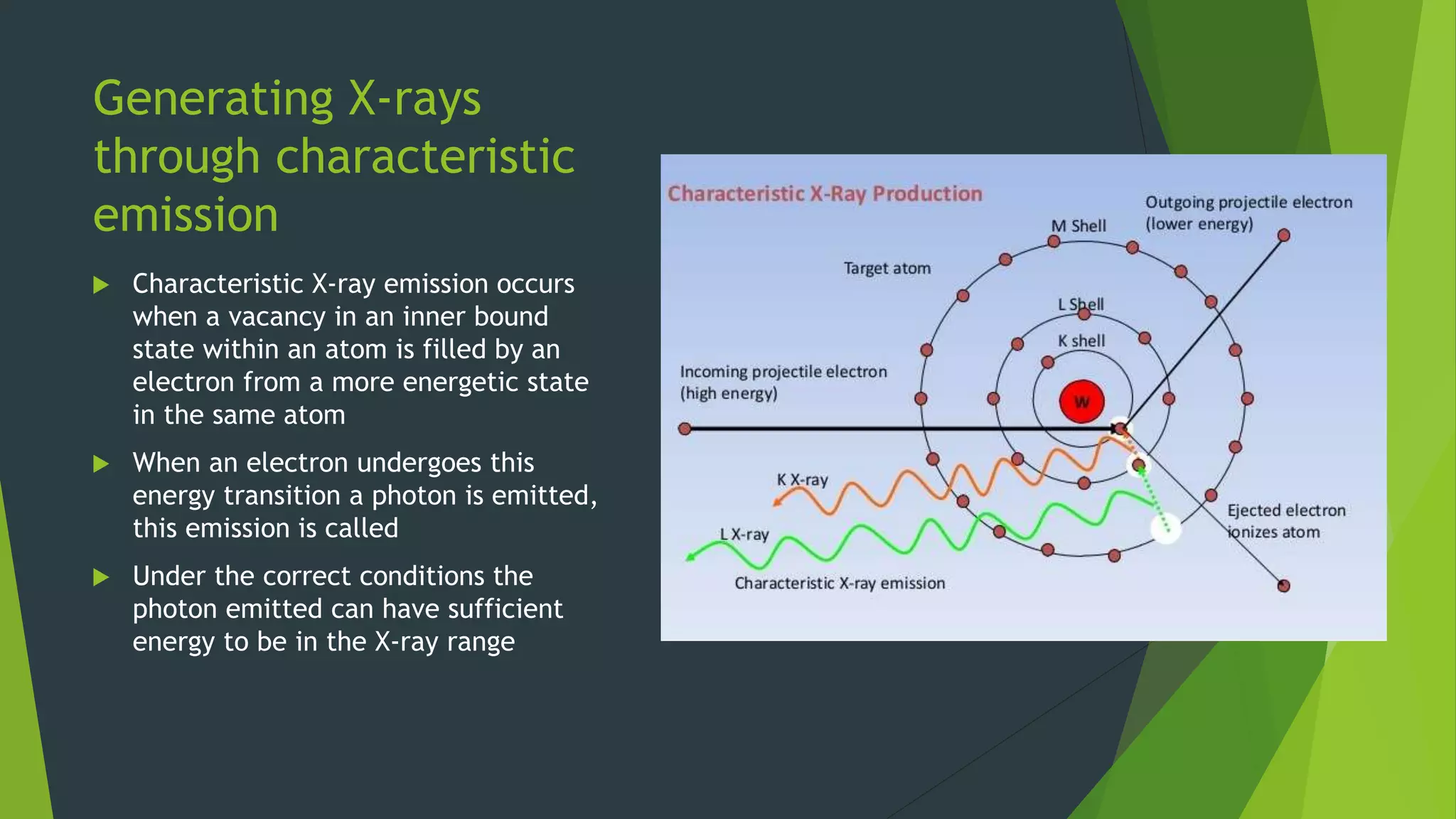

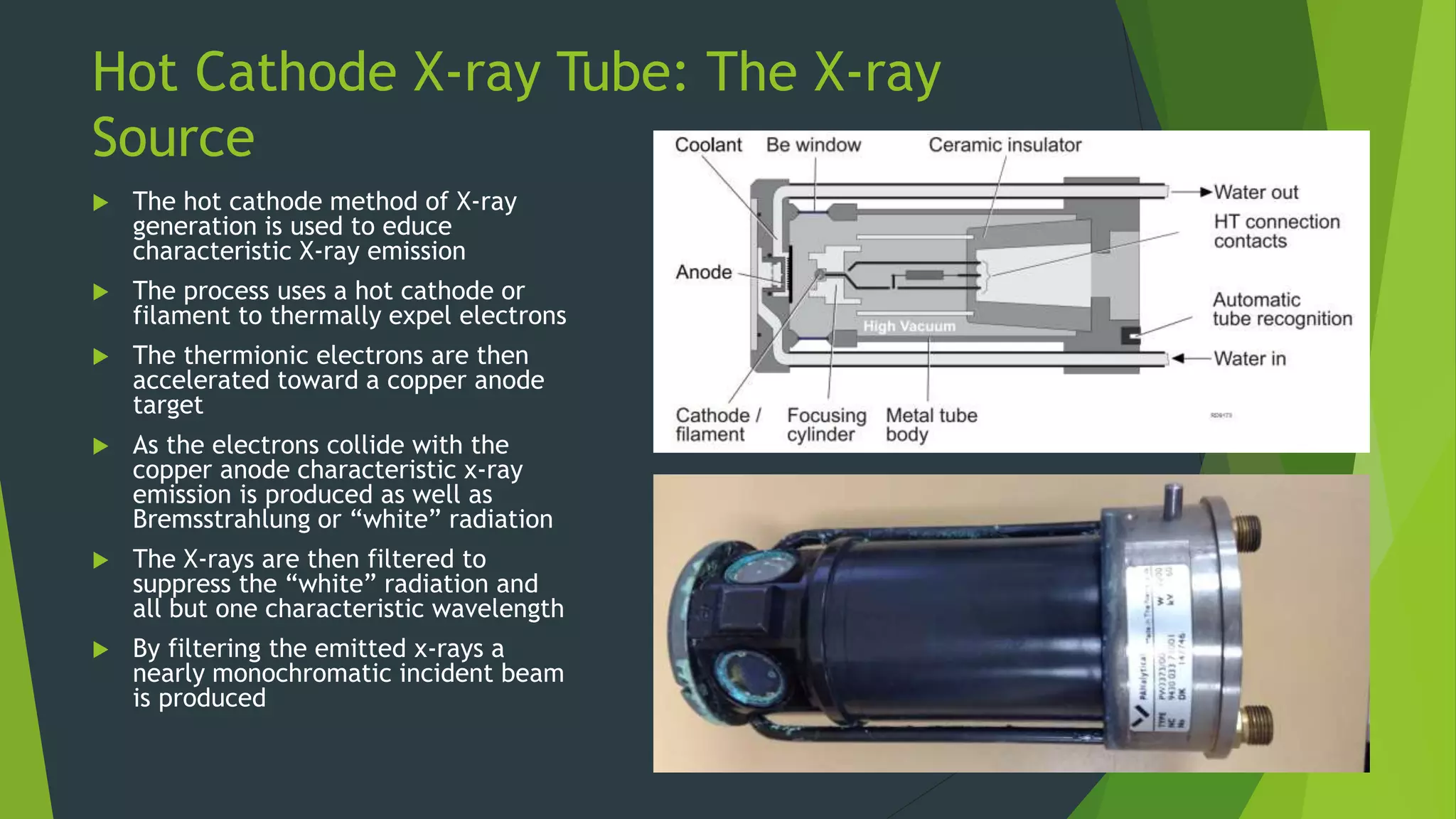

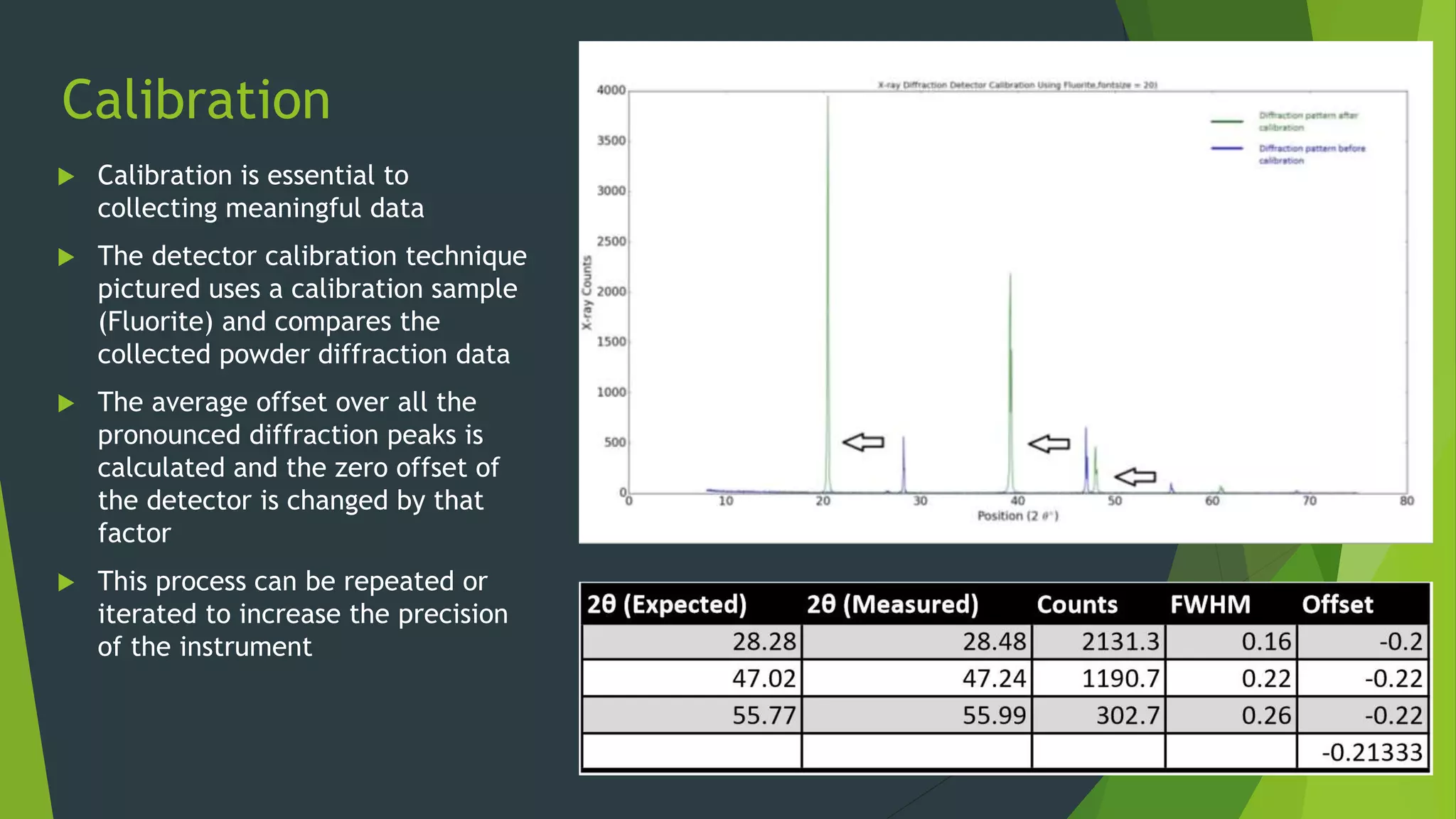

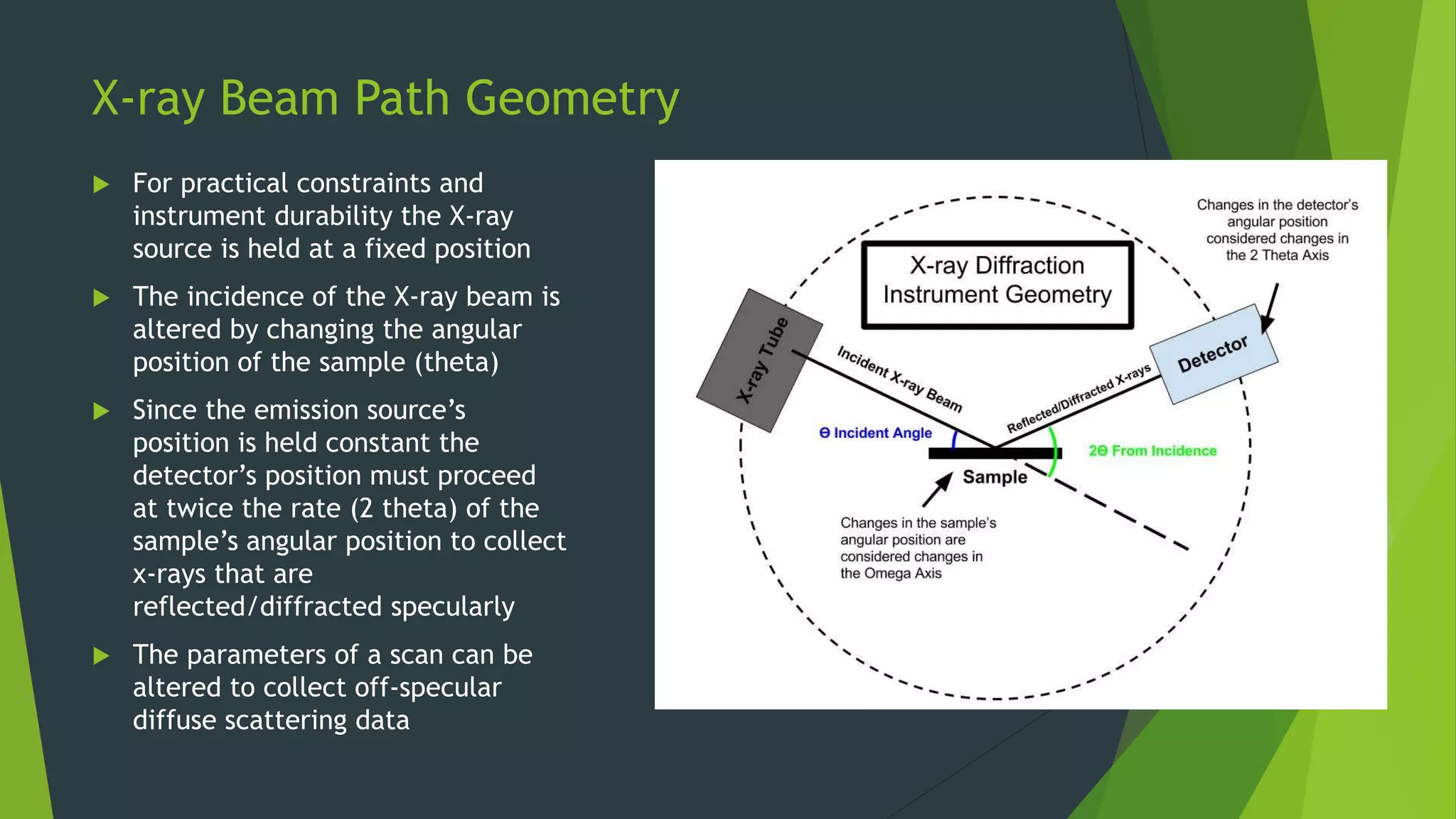

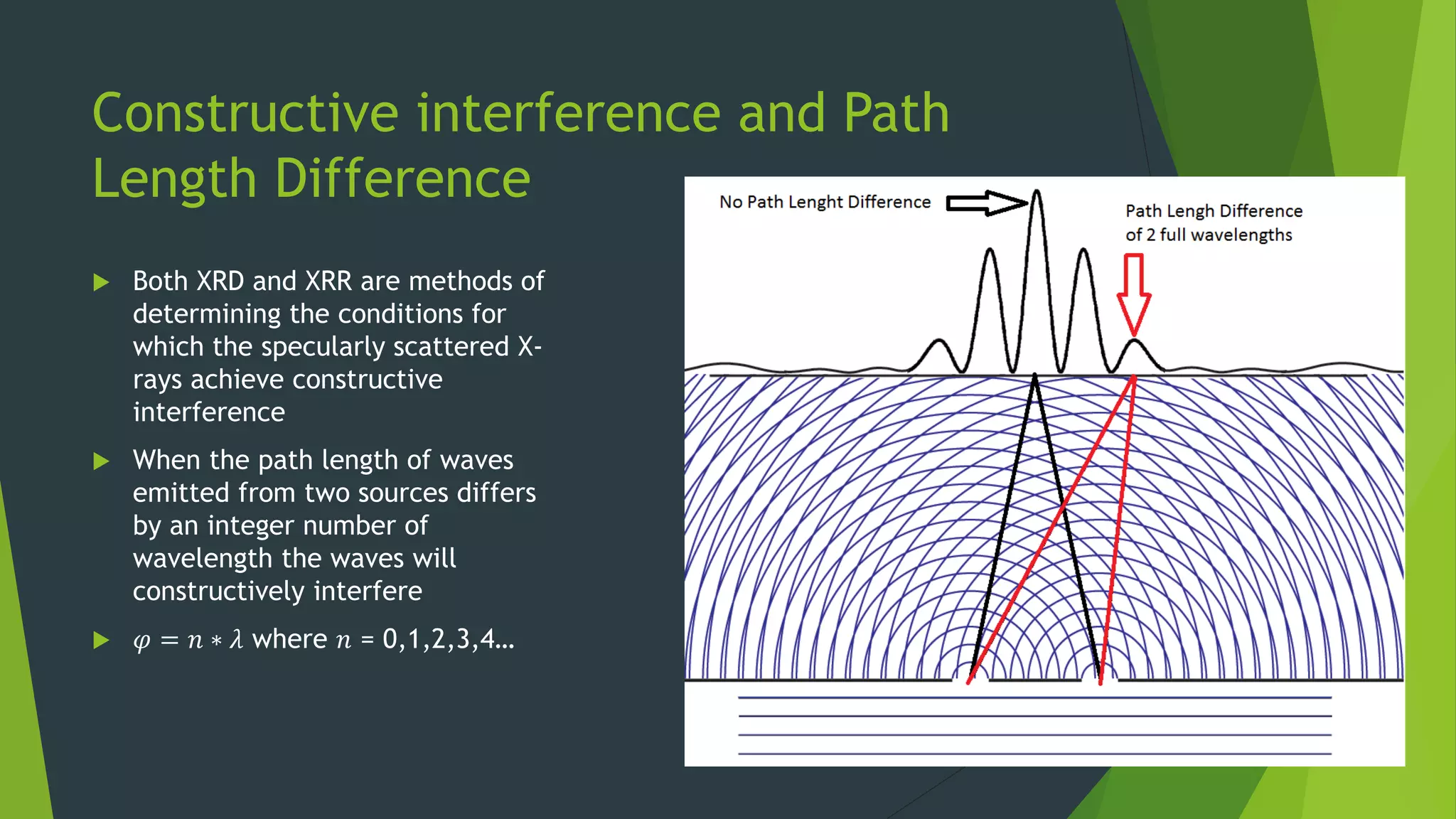

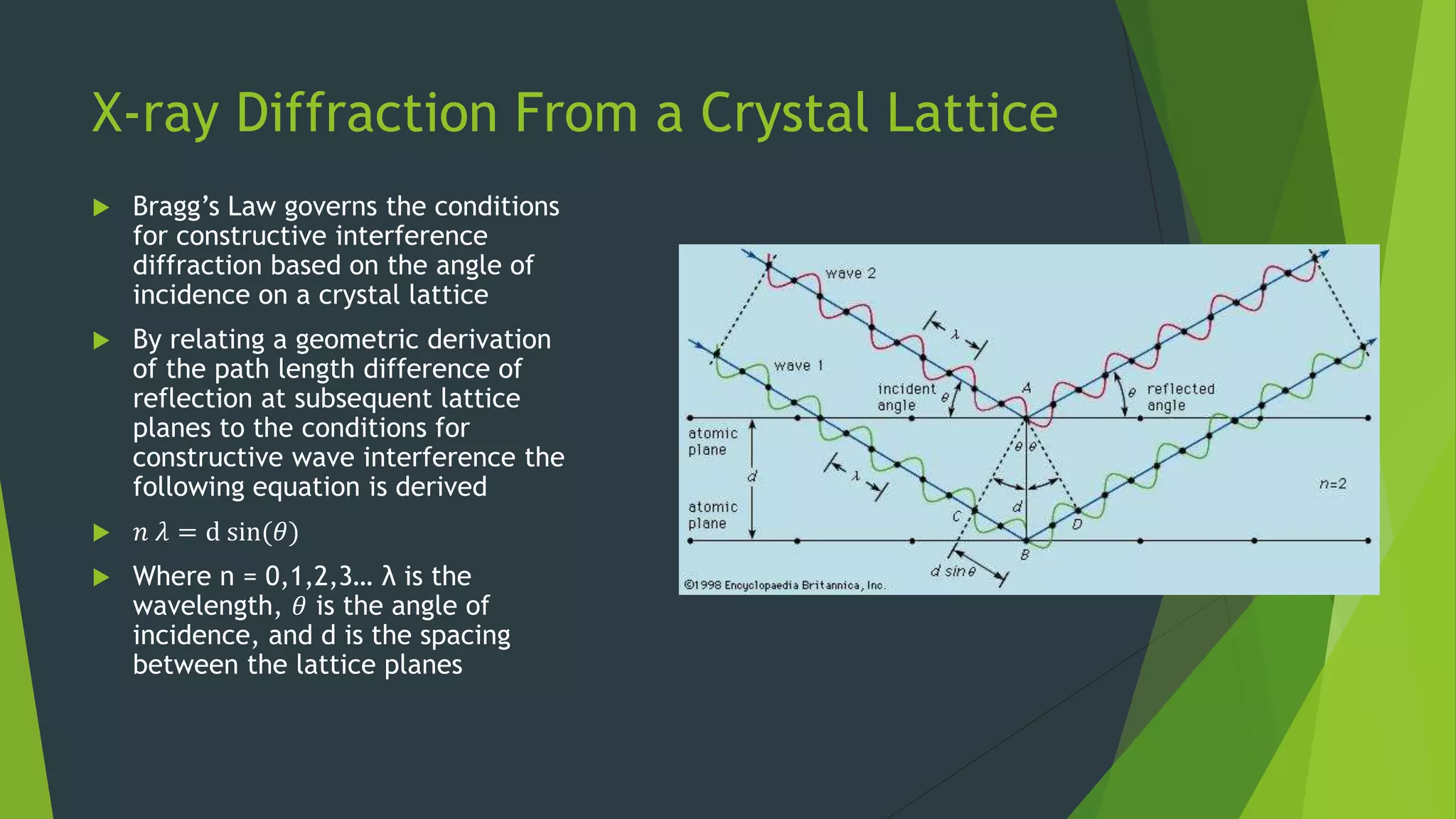

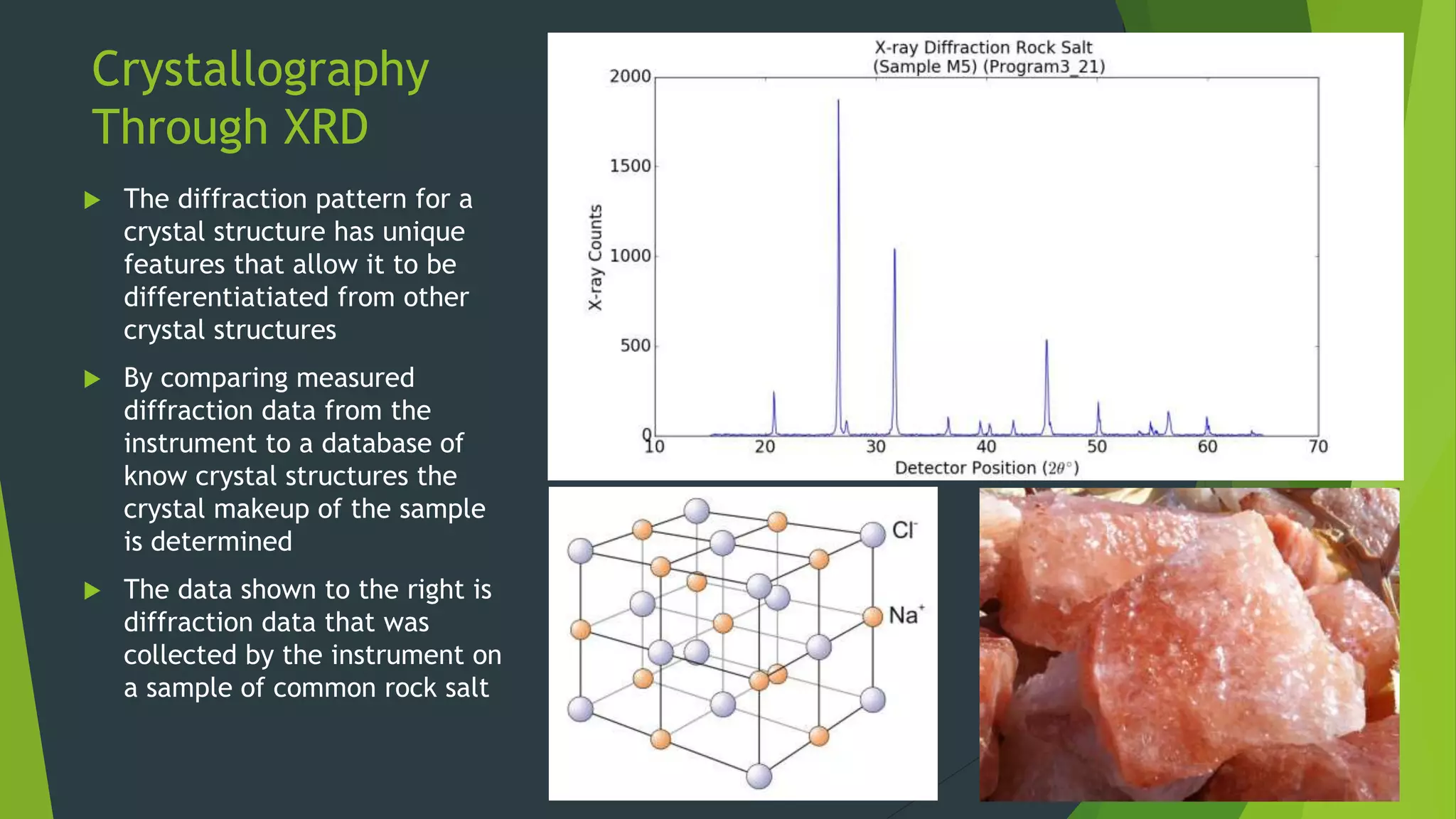

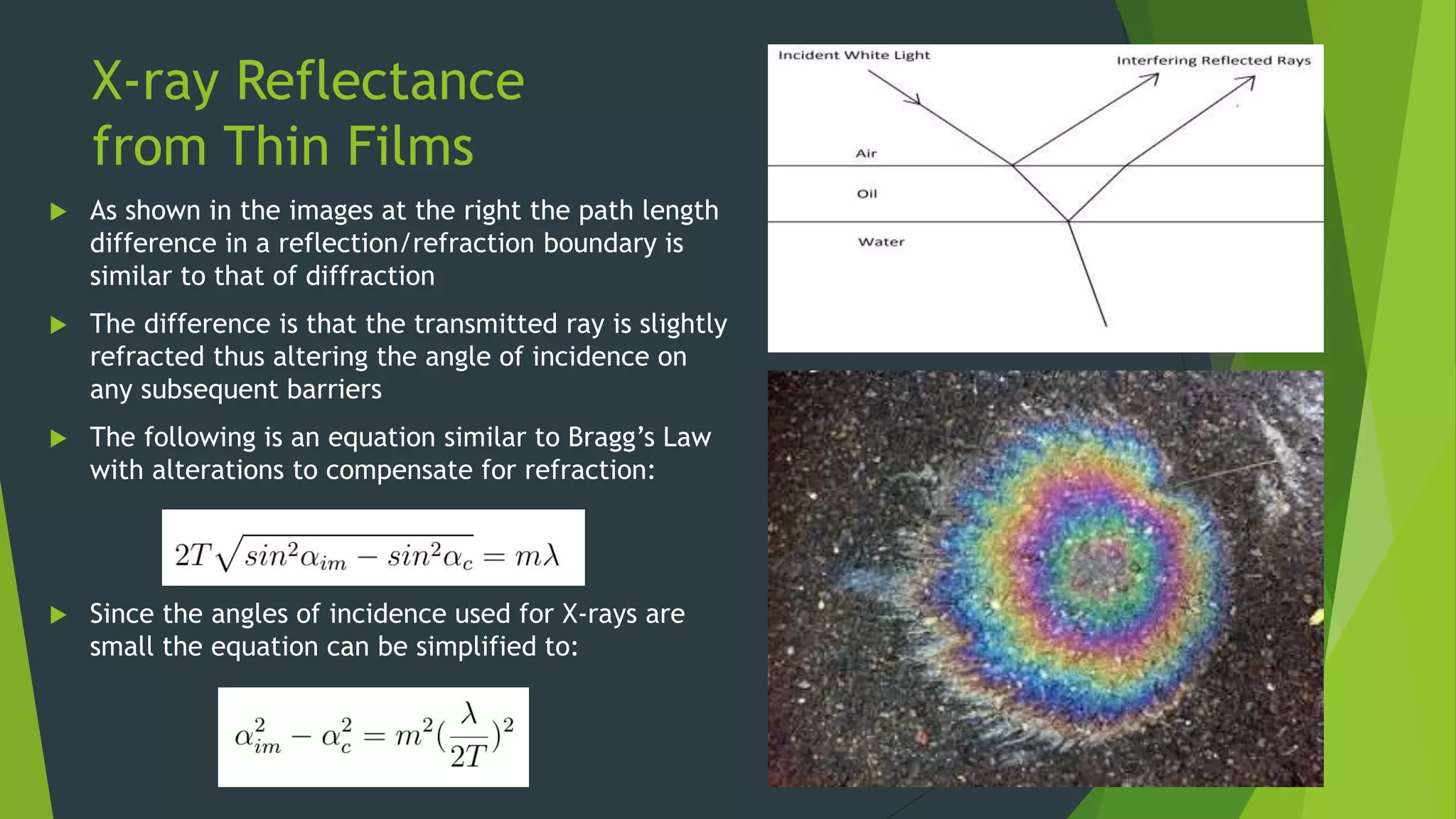

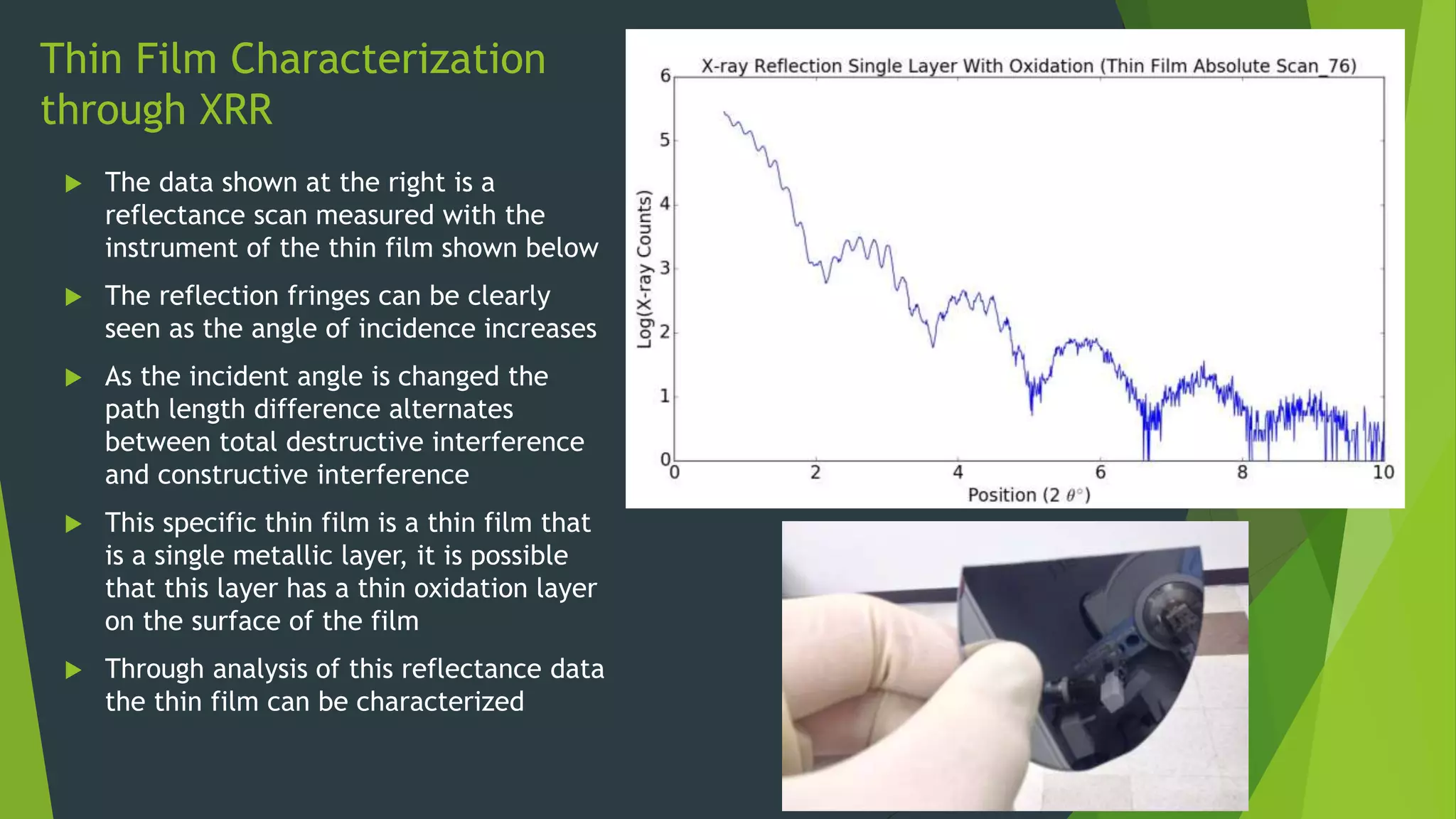

This document summarizes the qualification of a Phillips X'pert Diffractometer for applications in X-ray diffraction and reflection. It describes how the instrument can be configured for powder diffraction and thin film reflectance measurements. It also outlines the X-ray generation process using a hot cathode tube, detection using a xenon gas chamber, calibration techniques, and how Bragg's law and thin film reflectance principles apply to analyzing diffraction and reflectance data to characterize crystal structures and thin film properties. Future work is proposed on analyzing multi-layer thin films and improving crystallography of impure samples.