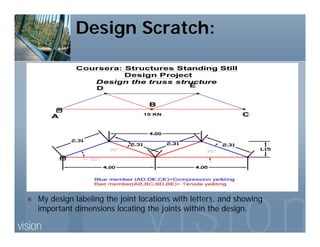

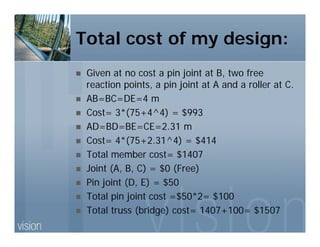

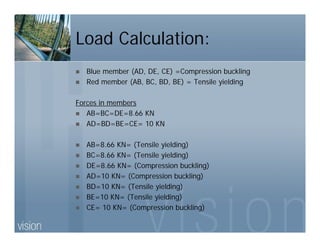

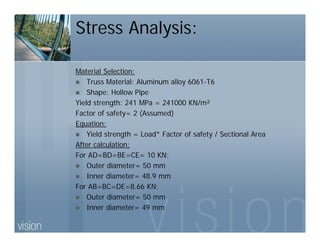

The document discusses the design and cost analysis of a truss structure, focusing on joint locations, dimensions, and material selection. Load calculations determine the forces acting on various members of the structure, categorizing them into compression and tensile forces. Final remarks indicate potential failure points in the design based on the stress analysis conducted.