Embed presentation

Download to read offline

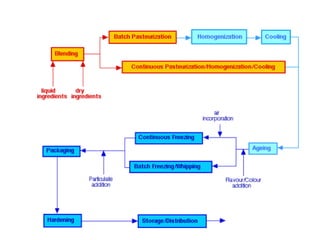

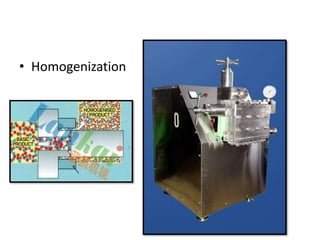

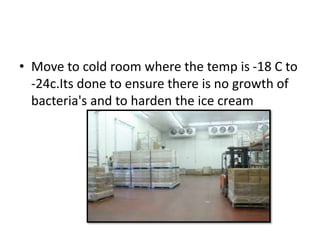

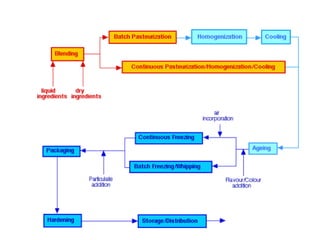

The production process for Lazza ice creams involves 1) mixing water, sugar, SMP and stabilizers in tanks, 2) pasteurizing the mix at 75C then rapidly cooling to -4C to kill bacteria, 3) homogenizing and aging the mix for up to 8 hours in a vat where it cools to 5C, 4) passing the mix through a continuous freezer where air is pumped in to give the mix its structure at 5C, 5) packing the ice cream into cones, cups, balls and family packs, and 6) moving the packed ice cream to a cold room at -18C to -24C to prevent bacteria growth and harden the ice cream before 7) quality checking