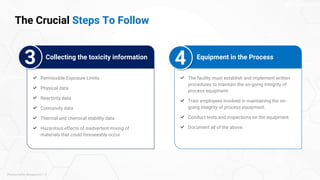

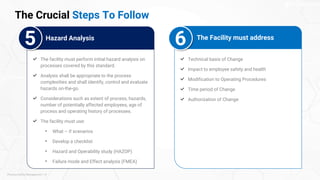

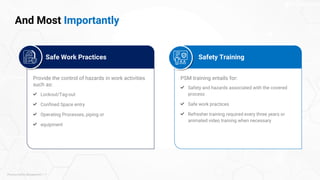

The document provides a comprehensive checklist for Process Safety Management (PSM), detailing essential elements such as employee participation, hazard assessments, and safe work practices. It highlights the importance of PSM through case studies of past disasters and emphasizes ongoing equipment integrity and employee training. The document also promotes Tech EHS's animation services as a means to enhance safety training and improve understanding of PSM methodologies.