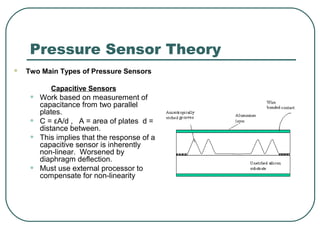

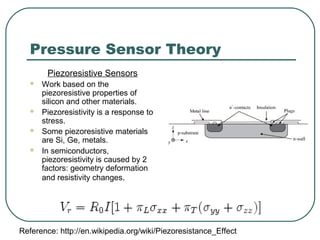

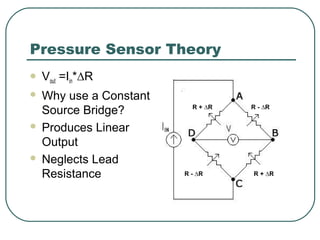

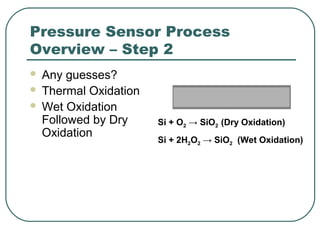

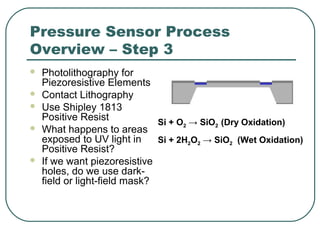

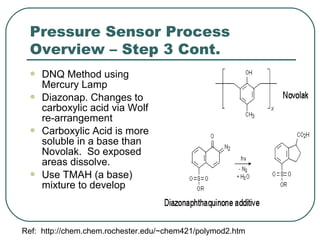

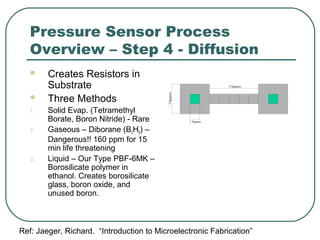

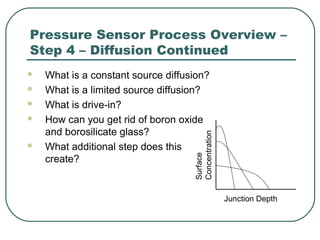

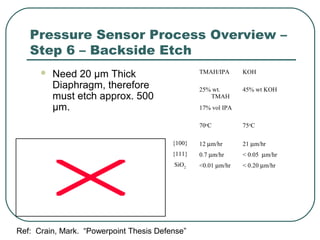

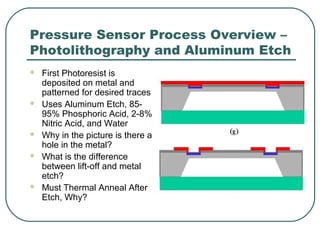

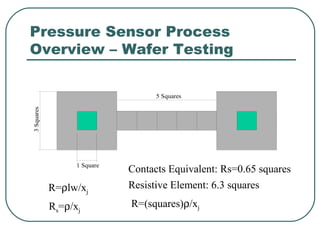

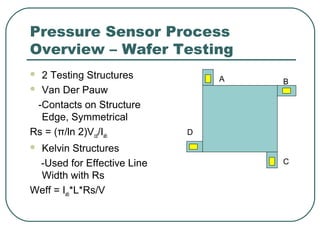

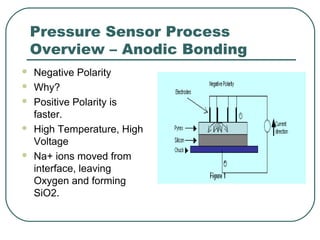

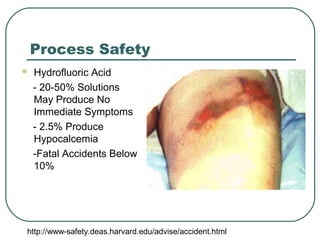

This lecture covers pressure sensor theory, fabrication processes, and safety concerns. It discusses two main types of pressure sensors - capacitive and piezoresistive - and describes the process used to create a piezoresistive pressure sensor using boron diffusion on silicon wafers. Key steps include cleaning, oxidation, photolithography, diffusion, backside etching, contact patterning, and anodic bonding. Safety hazards from chemicals like hydrofluoric acid are also addressed.