The document analyzes the conduction modes and efficiency of buck-boost, buck, and boost power converters. Simulation results show that continuous conduction mode (CCM) has the highest efficiency for all three converters. For a given duty cycle, increasing the inductor value decreases the peak-to-peak ripple. The conduction mode can also be varied by keeping the inductance constant and changing the duty cycle, which keeps the ripple value the same. Therefore, the filter is designed for a specific inductance value. Tables of results are presented comparing efficiency for different conduction modes under varying duty cycles and inductance values.

![Power Converters

Note:

All simulation results are taken by using mosfet at frequency of

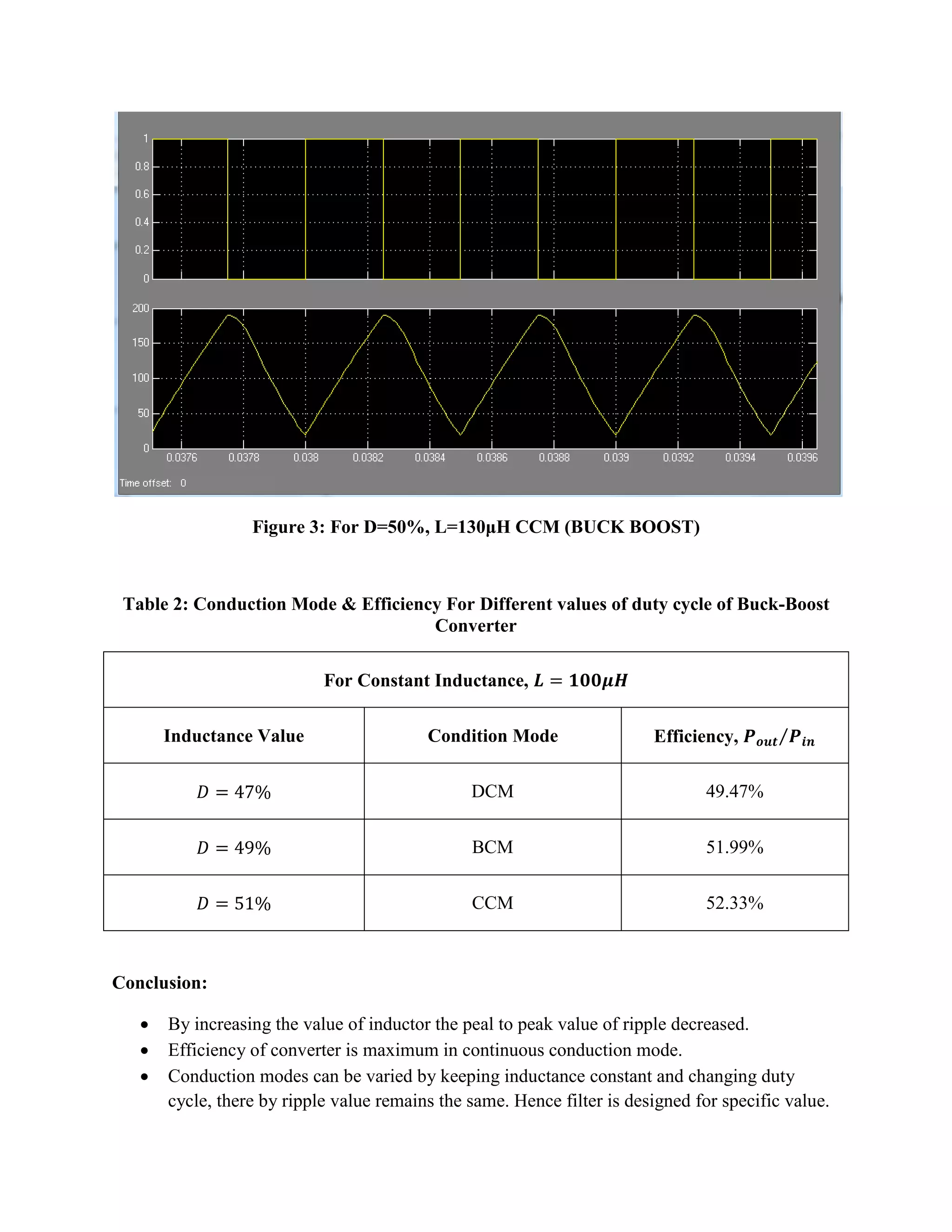

Buck BOOST CONVERTER

Table 1: Conduction Mode & Efficiency For Different values of duty cycle of Buck-Boost Converter

For Constant Duty Cycle,

Inductance Value

Condition Mode

Efficiency,

DCM

50.71%

BCM

57.02%

CCM

57.53%

Continuouspowergui v+ - V2v+ - V1Scope2Scope1R1PulseGenerator1gmDSMosfetInMeanMean Value3L1i+ - IL2i+ - IL1i+ - IL[H] Goto[H] FromDisplay1Diode1DC Voltage Source1C1](https://image.slidesharecdn.com/powerconverterreporttt-141103072535-conversion-gate02/75/Power-converter-report-2-2048.jpg)

![Buck CONVERTER

Table 3: Conduction Mode & Efficiency For Different values of Inductance of Buck Converter

For Constant Duty Cycle,

Inductance Value

Condition Mode

Efficiency,

DCM

62.27%

BCM

64.78%

CCM

66.56%

Continuouspowerguiv+ - VScope3RPulseGeneratorgmDSMosfet1InMeanMean Value3InMeanMean Value2InMeanMean Value1Li+ - I_L2i+ - I_L1i+ - I_L[E] Goto1Divide2Divide1Divide0.6656DisplayDiodeDC Voltage Source10ConstantC](https://image.slidesharecdn.com/powerconverterreporttt-141103072535-conversion-gate02/75/Power-converter-report-5-2048.jpg)

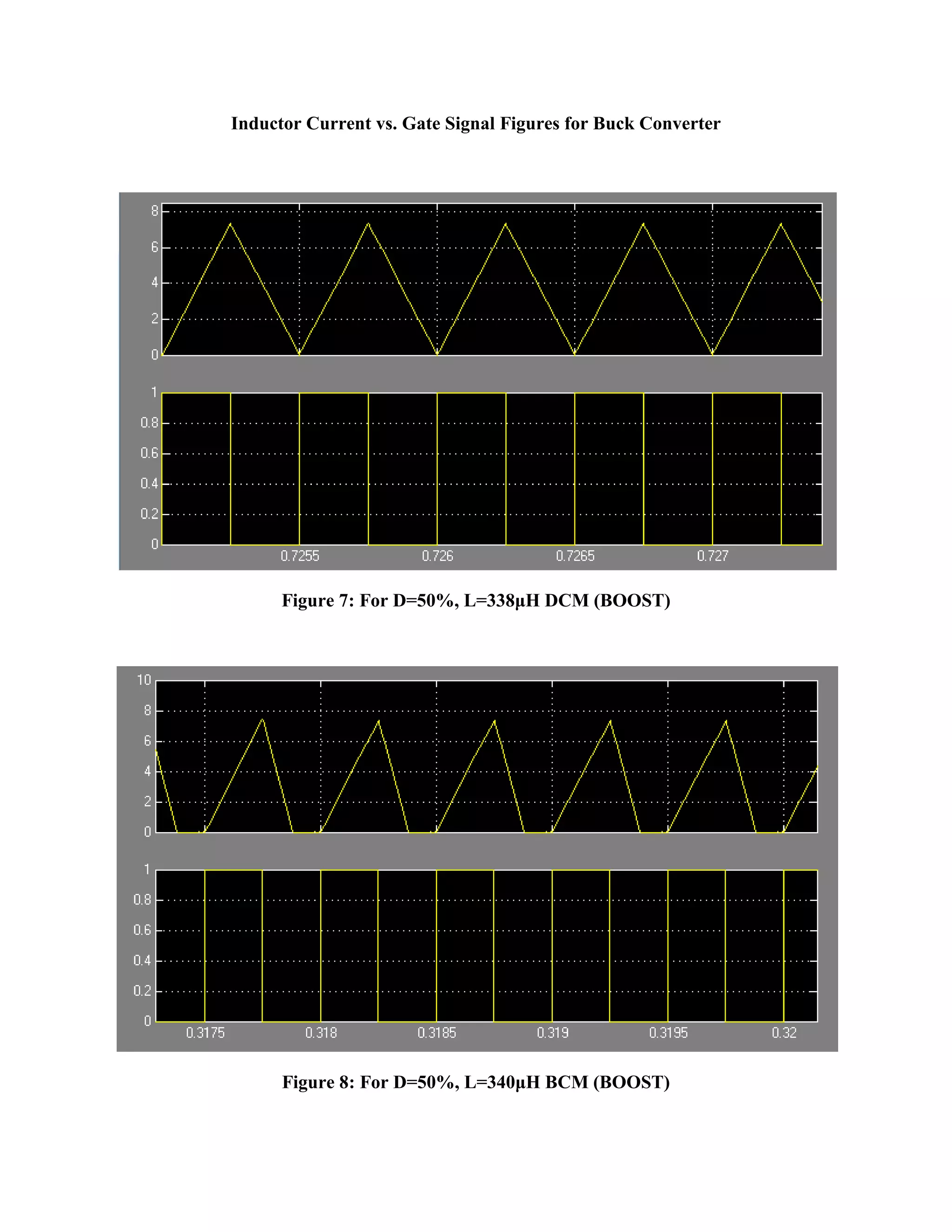

![Boost CONVERTER

Table 5: Conduction Mode & Efficiency For Different values of Inductance of Boost Converter

For Constant Duty Cycle,

Inductance Value

Condition Mode

Efficiency,

DCM

74.91%

BCM

76.47%

CCM

79.28%

Continuouspowerguiv+ - V2Scope1R2PulseGenerator2InMeanMean Value3InMeanMean Value2InMeanMean Value1L2 gm12 Ideal Switch2i+ - I_L1[A] Goto2Divide2Divide1Divide0.5182DisplayDiode2DC Voltage Source2i+ - Current Measurement10ConstantC2](https://image.slidesharecdn.com/powerconverterreporttt-141103072535-conversion-gate02/75/Power-converter-report-8-2048.jpg)