The document discusses key aspects of workplace cleanliness in the food industry, emphasizing its role in enhancing employee productivity and safety. It also explores the application of deep learning technologies in agri-food systems, notably for quality control and efficiency in food processing. Additionally, it highlights recent trends and challenges in the food industry, including innovations in frozen foods and fluctuations in edible oil prices.

![Deep Learning in Agri-Food Systems

Vol .03-Issue .25-June 2024

DESIGN+BUILD FOOD FACTORIES. ONE STOP ENGINEERING SOLUTION

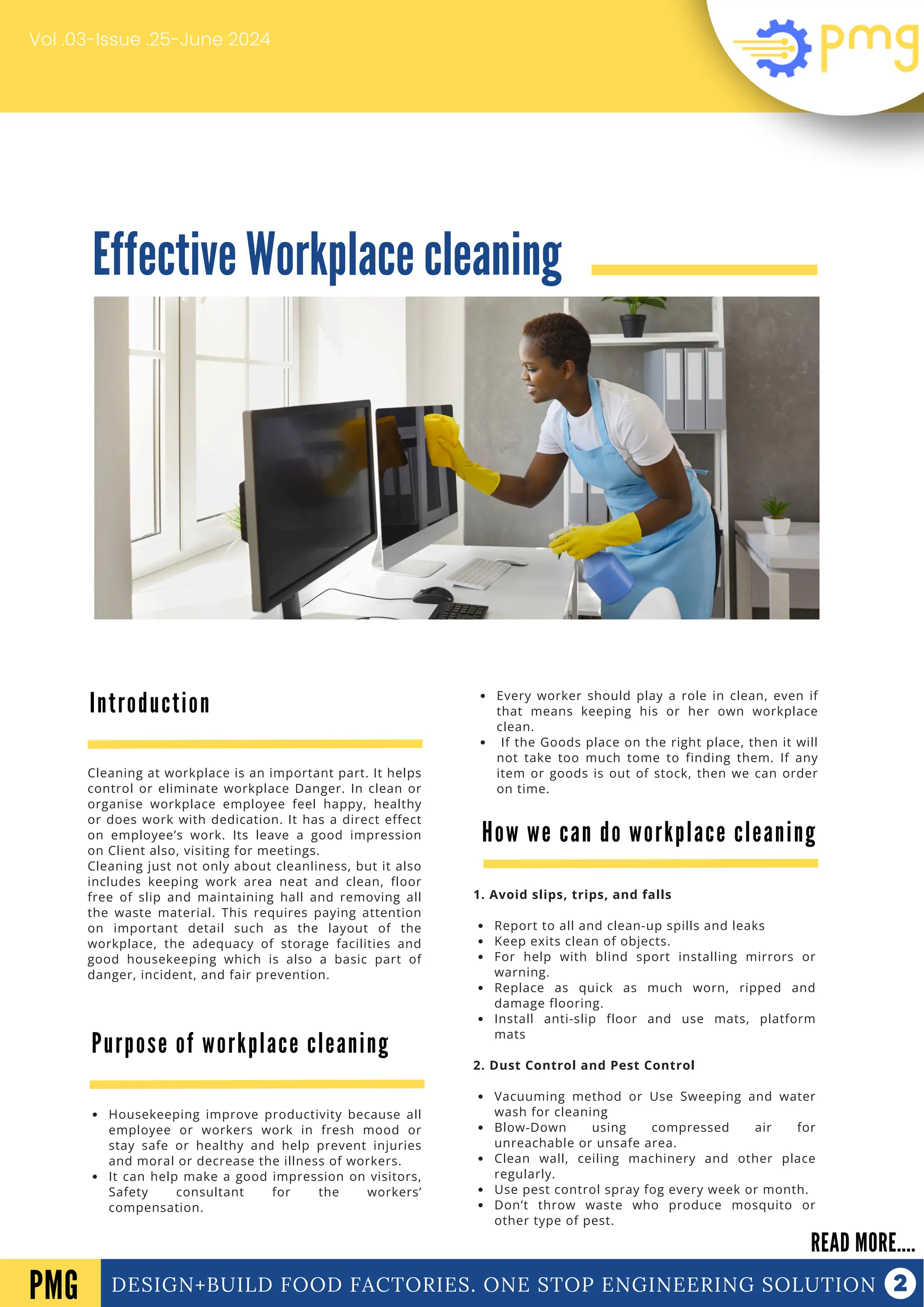

Introduction

READ MORE....

PMG

Deep Learning (DL) is a subset of Machine

Learning, which itself is a subset of Artificial

Intelligence. Deep Learning employs a variety of

neural network (NN) architectures and algorithms

for pattern recognition and data analysis. This soft

computing technique is bringing revolutions in the

field of data science, as it can be used to analyze

huge volumes of data in all possible forms viz.

text, audio, 2D/3D image, and videos into

meaningful insights. In recent times, the agri-food

industry has also largely benefited from the

development in this field. In food processing units,

deep Learning is being implemented in machine

vision systems for inspecting inline processes,

quality of raw materials, and finished goods.

At the farm level, deep learning technology has

been successfully applied in autonomous robotic

systems tasked with picking agro-commodities

with desired characteristics. Deep learning is also

being used to monitor vegetation using low-

altitude aerial systems coupled with a wide variety

of sensors for data collection. This technique is

favorable over other AI tools as it is versatile with

the type of input data and its performance is

directly proportional to the amount of data fed.

The nature of data sourced from agro, and

biological systems is complex as it can vary from

continuous spectral information to spatial RGB

images or a combination of both.

The artificial neural network (ANN) architecture is the

simplest model for DL. It is a computational system

composed of the systematic interconnection of many

simple processing neurons operating in parallel whose

function is determined by network structure, connection

strengths, and the processing performed at the neurons

[1]. They are designed to mimic the human brain’s

nervous system, to compute sophisticated computations

for a specific task. The ANN architecture comprises

several layers – an input layer where the data are

provided, hidden layers where classification tasks are

done, and the output layer predict the output. For an ANN

to predict future data, it must be trained first, further

which it becomes able to predict similar patterns. The

basic information processing unit of an ANN is the

neuron.

PROTEIN FUNCTIONALIZATION

PROTEIN FUNCTIONALIZATION

Artificial Neural Network

Convolutional Neural Network

CNN is a specialized type of NN designed to be applied in

computer vision tasks like image classification and object

detection. Convolutional layers are the fundamental

building blocks of CNNs. This layer performs an operation

called a ‘convolution’. A convolution is a linear operation

that involves the multiplication of a set of weights with

the input.](https://image.slidesharecdn.com/pmgnewslettervolume03-240702063914-59b07686/75/PMG-Newsletter-Volume-03-Issue-25-2-pdf-5-2048.jpg)

![DESIGN+BUILD FOOD FACTORIES. ONE STOP ENGINEERING SOLUTION

PMG

Vol .03-Issue .25-June 2024

Several researchers have implemented these

algorithms to solve crucial problems in the food

industry such as defects classification, shelf-life

prediction, dietary assessment, food

grading/sorting, inspection, etc. The process of

development and the forms of models that would

yield from DL implementation in the agri-food

system is not significantly different from those for

other systems. However, the information and

knowledge fed to the system as input data will help

to characterize the individual systems and their

features. Raw materials like fruits and vegetables

often have a non-visible defect in their surface, but

due to improper storage conditions, may get

affected by internal pest infestation and

pathological disorders. For instance, plantains with

preexisting internal damage conditions when stored

at optimum conditions (2% O2 and 5 – 10% CO2 at

10°C, 90% RH) will bypass a trained and experienced

eye. This, however, won’t be an issue if there were a

machine vision system in place.

Cleaning processing equipment requires a lot of

time and resources, including water. To address this

problem, research engineers at the University of

Nottingham have developed a system that uses DL

to reduce cleaning time and resources by 20 – 40%.

The system, which they call Self-Optimizing CIP,

uses ultrasonic sensing and optical fluorescence

imaging to measure food residue and microbial

debris in a piece of equipment and then optimize

the cleaning process [9].

Deep Learning in Cleaning

processing equipment

Application in the Agri-Food

Systems

Deep Learning in Quality Control

Quality control is a costly process, but a critical step

in the food industry. Traditional techniques are

time-consuming and hence machine vision systems

are being installed for better performance. In recent

times, several industries, as well as academic units,

have investigated the performance of models

suitable for specialized tasks. Similarly, Vasumathi

et al. [6] employed a 98.17% accurate DL technique

to sort pomegranate fruits into normal and

abnormal based on the color, number of fruit spots,

and shape of it.

Challenges in implementation

As opposed to the popular belief from science

fiction literature, achieving general artificial

intelligence is still a long journey. Till then, it is

important to develop specialized models for

completing specialized tasks. Even though a fully

functional model does not require any special

assistance while in operation, the initial setup cost

is significantly high. In terms of the complexity of

the overall deep learning-enabled system in the

industry, model selection is the most important step

in this process.](https://image.slidesharecdn.com/pmgnewslettervolume03-240702063914-59b07686/75/PMG-Newsletter-Volume-03-Issue-25-2-pdf-6-2048.jpg)