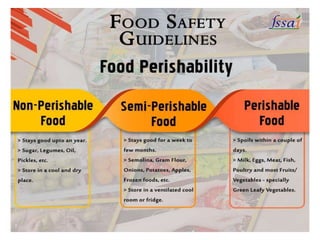

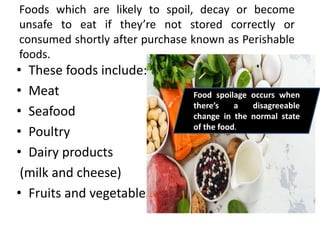

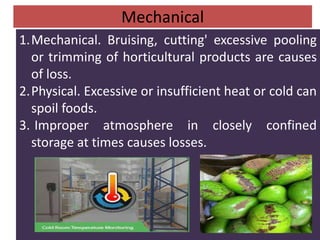

The document discusses various internal and external factors that affect the quality and post-harvest losses of fresh produce. It identifies several key causes of losses, including lack of temperature management, rough handling, poor packaging, and lack of education. Biological, microbiological, mechanical, physiological, and chemical factors can all contribute to losses between harvest and consumption, which amount to 30-50% of production in some areas. Proper temperature control, packaging, and education around quality maintenance are important for reducing post-harvest losses.

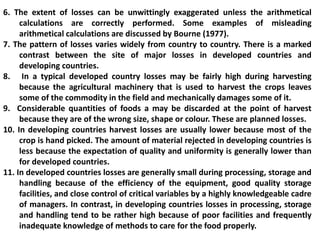

![Food losses categorized by the types and stages of the food pipeline. The

four columns (of a commodity type) denote the estimated waste

percentages in Europe, North America, Asia, and sub-Saharan Africa,

respectively. Notice that the bars show the food losses in percentage of

what enters at each step. The data for generating this figure are

obtained from Reference [77].](https://image.slidesharecdn.com/phe1-230202140359-be79dd1d/85/PHE-1-pptx-14-320.jpg)

![Key causes of food losses and waste (adapted with permission from

Reference [22]).](https://image.slidesharecdn.com/phe1-230202140359-be79dd1d/85/PHE-1-pptx-21-320.jpg)