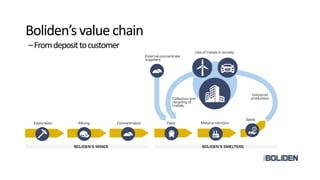

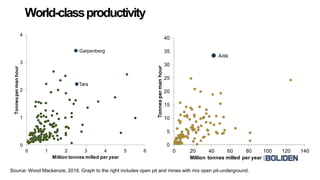

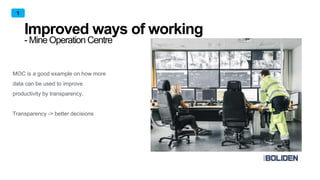

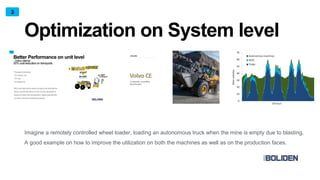

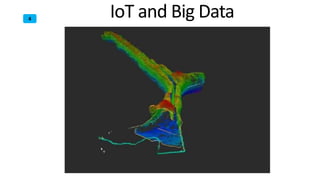

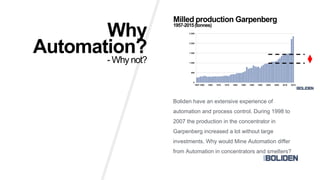

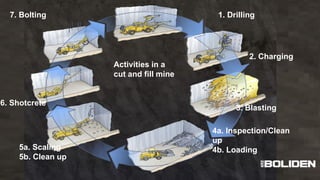

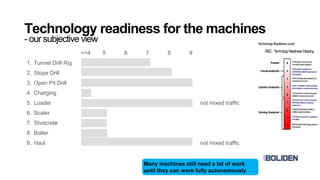

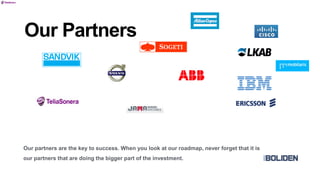

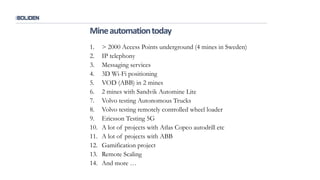

The document discusses Boliden's mine automation program. It aims to improve productivity and utilization in mines through automation. Boliden mines copper, zinc and other metals. Productivity is challenged by issues like blast ventilation times, machine breakdowns and shift changes. The mine automation program seeks to optimize operations through technologies like remote operation, 3D mapping, Internet of Things sensors and big data analysis. This could allow some mines to operate 24/7 and improve utilization of equipment like loaders and trucks. Several automation projects are already underway with partners like Volvo, Sandvik, Ericsson and ABB. The goal is for automation to improve safety and productivity while reducing costs and environmental impact from mines.