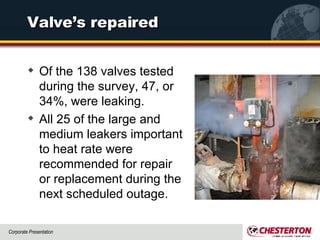

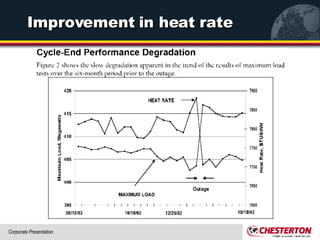

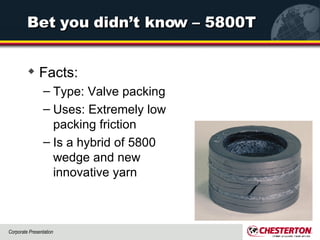

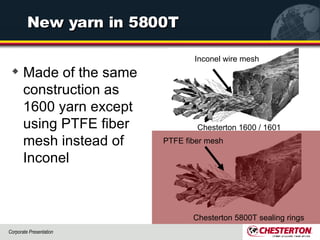

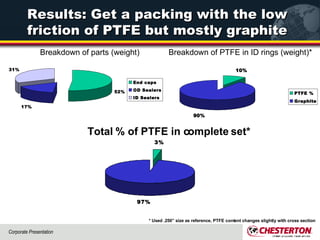

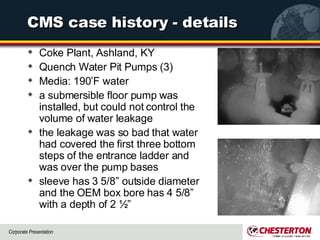

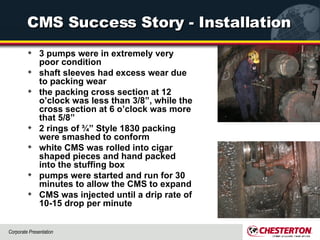

The document summarizes information from Chesterton about valve packing solutions. It highlights a case study where repairing leaking valves at a power plant increased efficiency by 9.9 MW. It also describes a new valve packing product, the 5800T, which combines the low friction of PTFE with the durability of graphite. Finally, it discusses a successful application of Chesterton packing at a coke plant where it significantly reduced water leakage from pumps.

![Any questions… If you have any questions or comments about this on-line newsletter please contact [email_address] Also please email any case histories you might want to share.](https://image.slidesharecdn.com/packing-newsletter-august-20072503/85/Packing-Newsletter-August-2007-14-320.jpg)