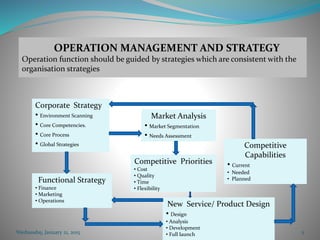

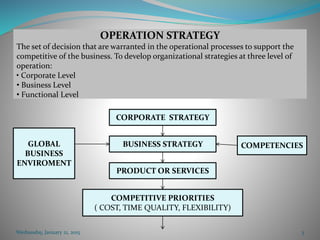

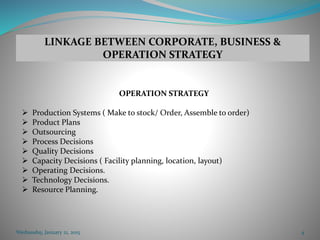

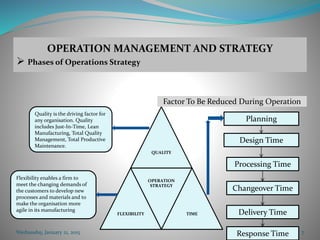

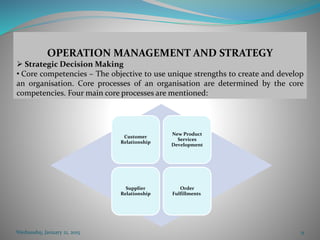

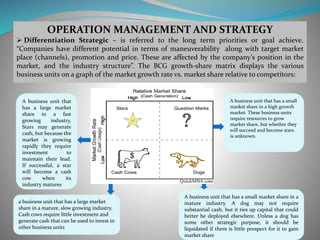

The document discusses key aspects of operation management and strategy. It defines operation management as the systematic design, direction, and control of processes that transform inputs into services. It identifies the five key components in any operation as plants, people, parts, processes, and planning/control. It then discusses elements of operation strategy including production systems, facilities, product/service design, quality, flexibility, and time. Finally, it covers topics like competitive priorities, industry best practices, manufacturing strategies, and the link between corporate, business and operation strategies.