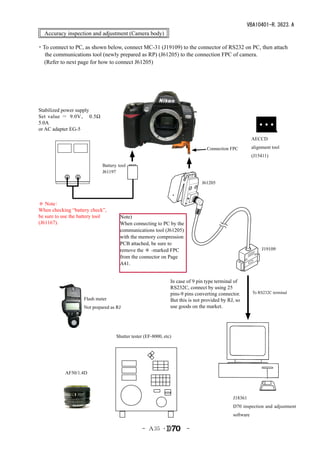

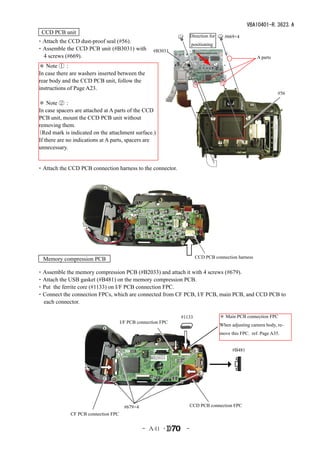

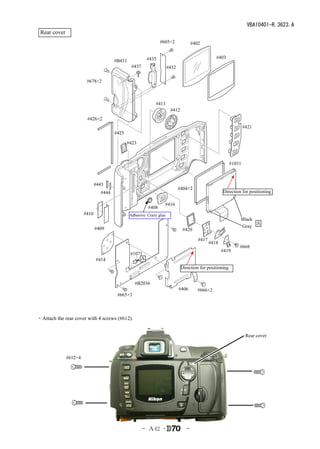

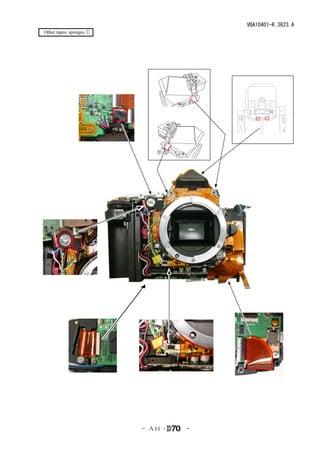

This document provides specifications for a Nikon single-lens reflex digital camera with interchangeable lenses. Key details include an effective pixel count of 6.1 million, compatibility with Nikkor F-mount lenses, autofocus and exposure capabilities, storage on CompactFlash memory cards, and power supplied by one EN-EL3 battery. Measurements of the camera body are also listed.