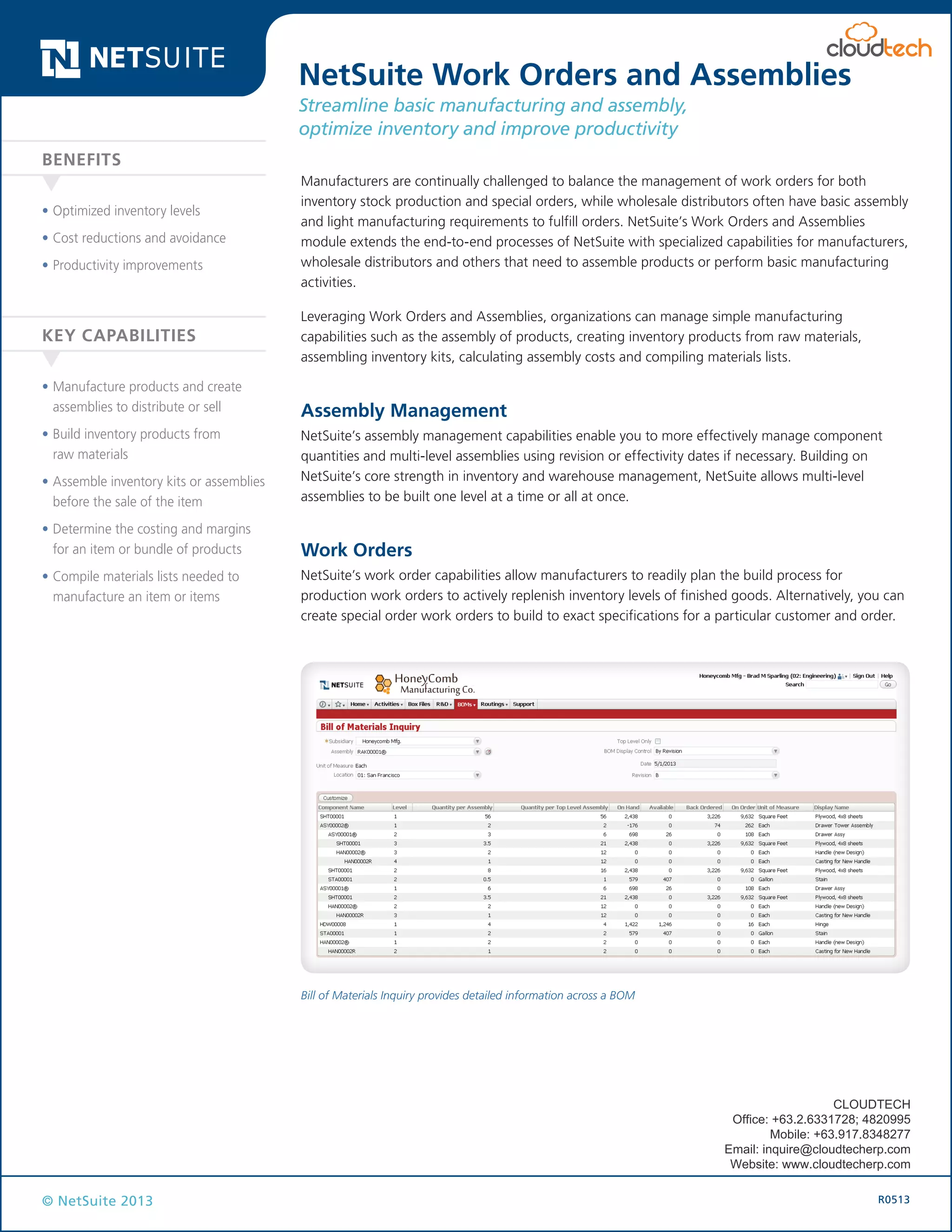

The document describes Netsuite's work orders and assemblies module, designed to streamline manufacturing processes and optimize inventory management for manufacturers and wholesale distributors. Key features include assembly management, work order capabilities, demand-based inventory replenishment, and product history tracking, allowing organizations to improve productivity and reduce costs. The module integrates with Netsuite's core strengths in inventory and warehouse management to enhance overall operational efficiency.