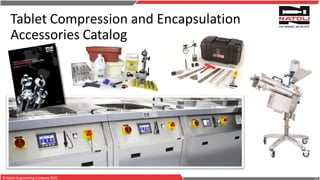

Natoli Engineering is a leading provider of tablet compression equipment and services, operating for almost 50 years. It offers a full range of tablet compression tools and presses, as well as refurbishing, replacement parts, analytical software, technical training, and consultation services. Natoli has manufacturing and technical facilities across the United States and in Poland and California. It assists customers with tablet design, tooling selection, process troubleshooting, and other services to optimize tablet production.