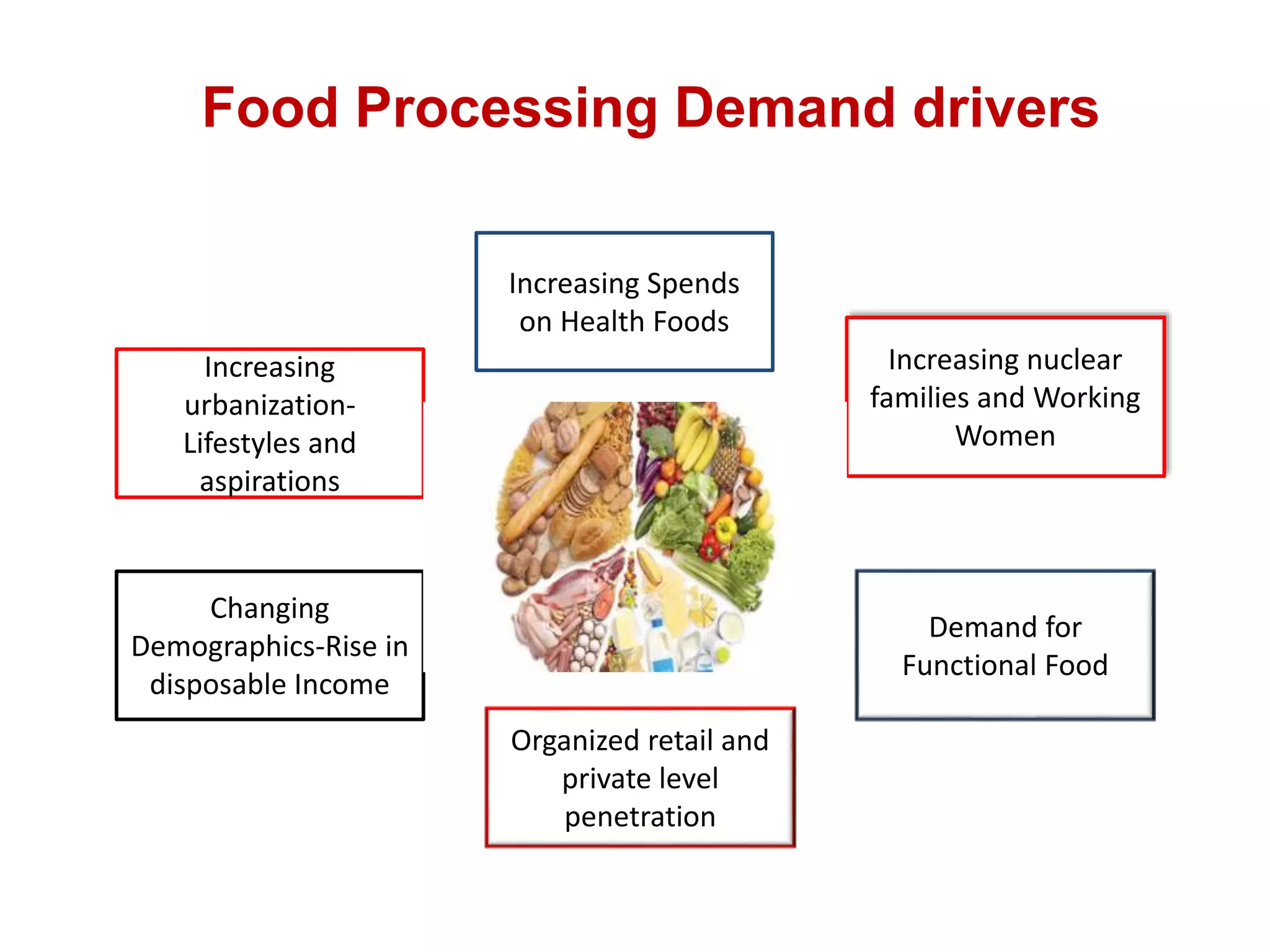

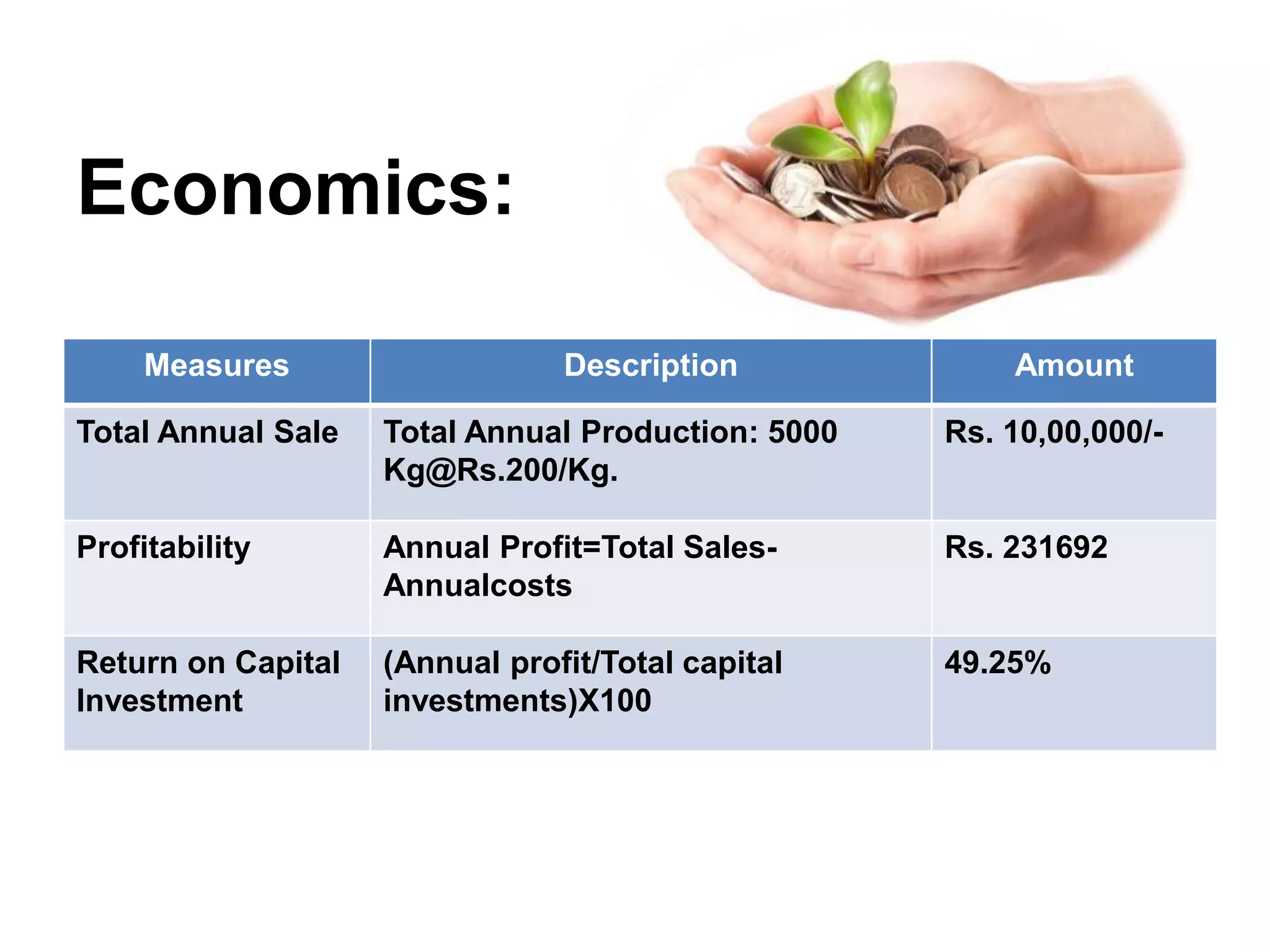

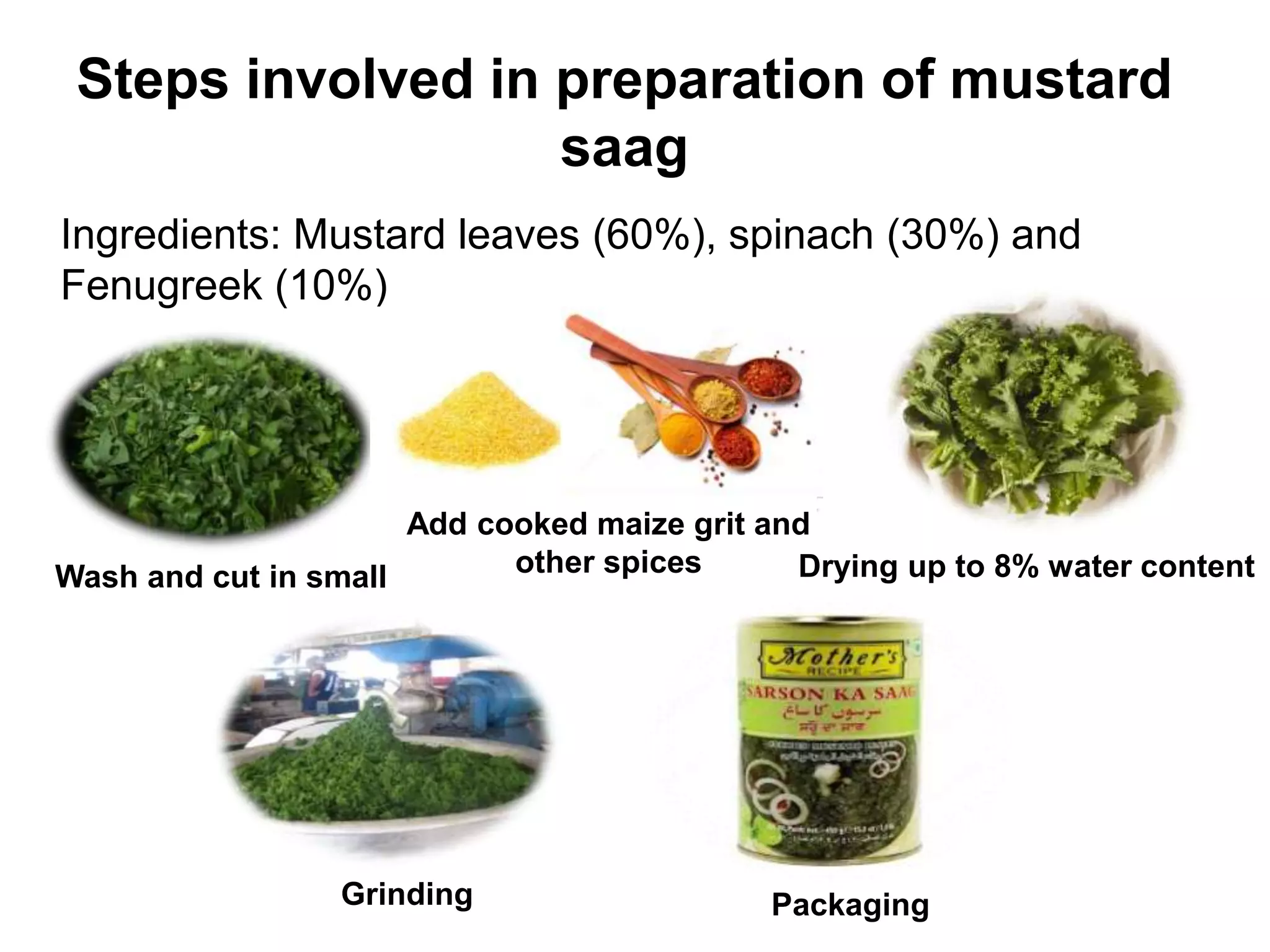

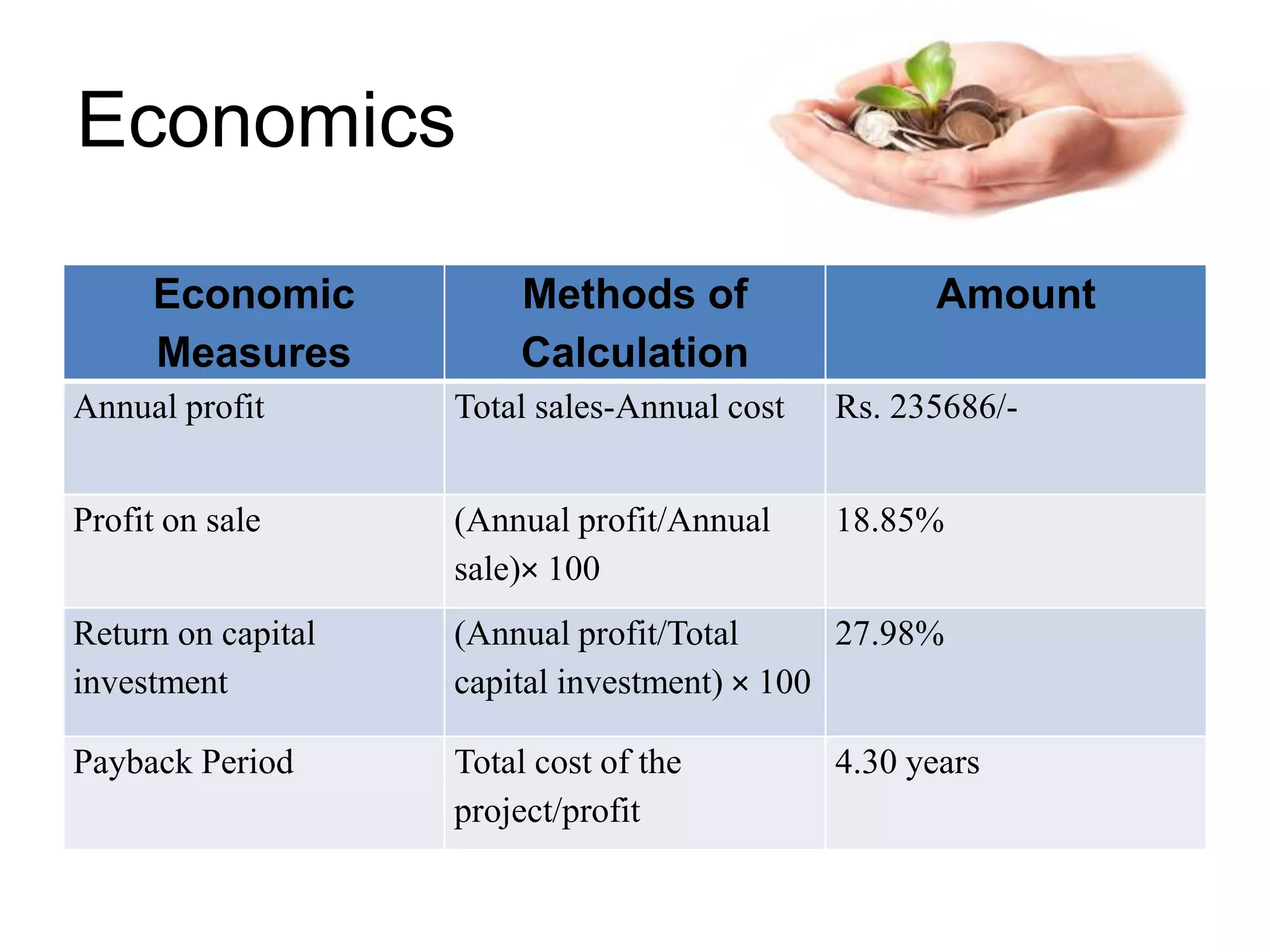

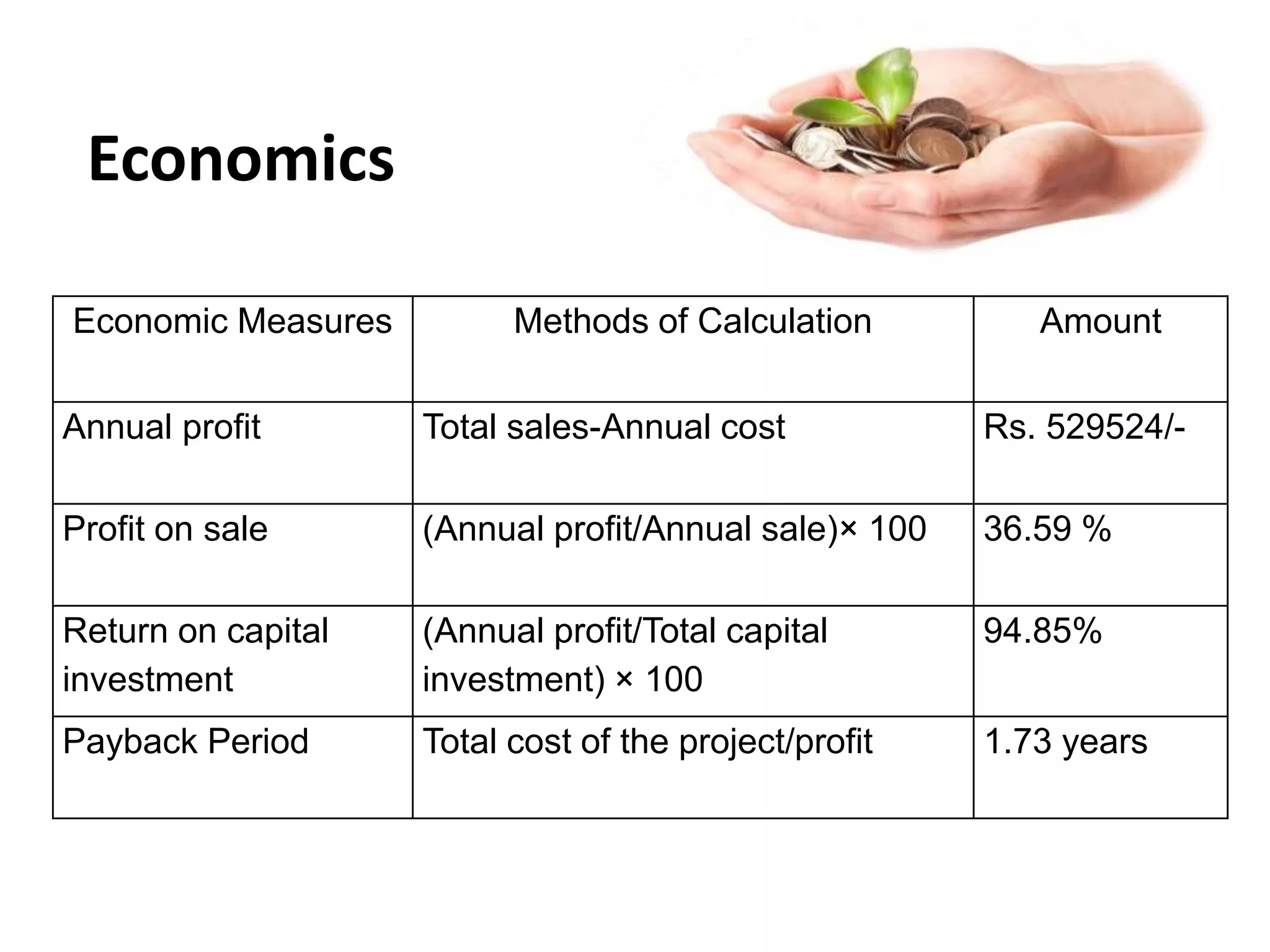

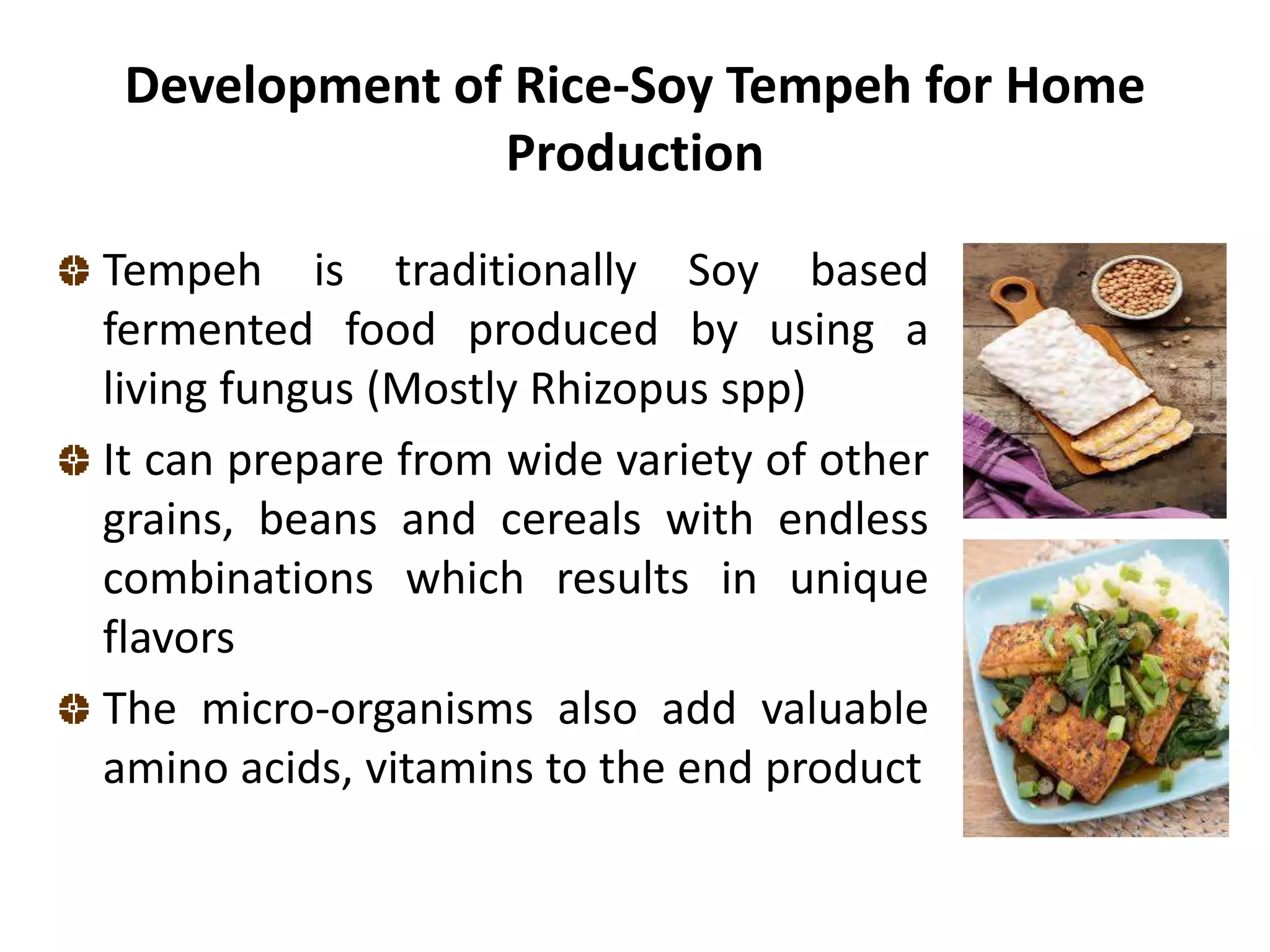

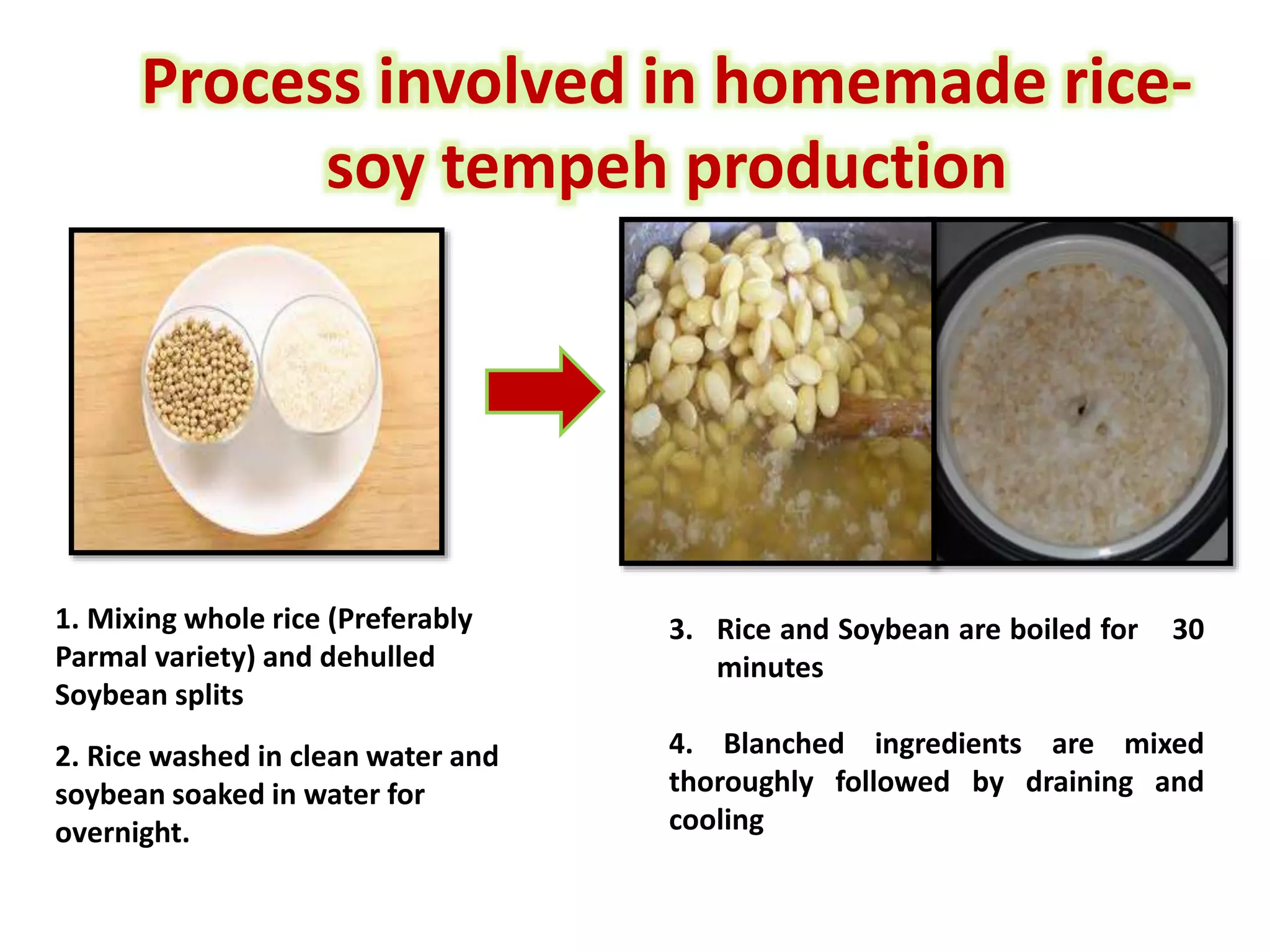

This document provides information on various methods of value addition for agricultural products in India to enhance nutritional security. It discusses the need for value addition given India's large agricultural output and discusses technologies like osmotic dehydration to make pineapple candy, ready-to-eat mixes from millets and mustard, rice-soy tempeh, and meat products. The production processes, economics, and potential contacts for equipment are summarized for several of these low-cost value addition methods.