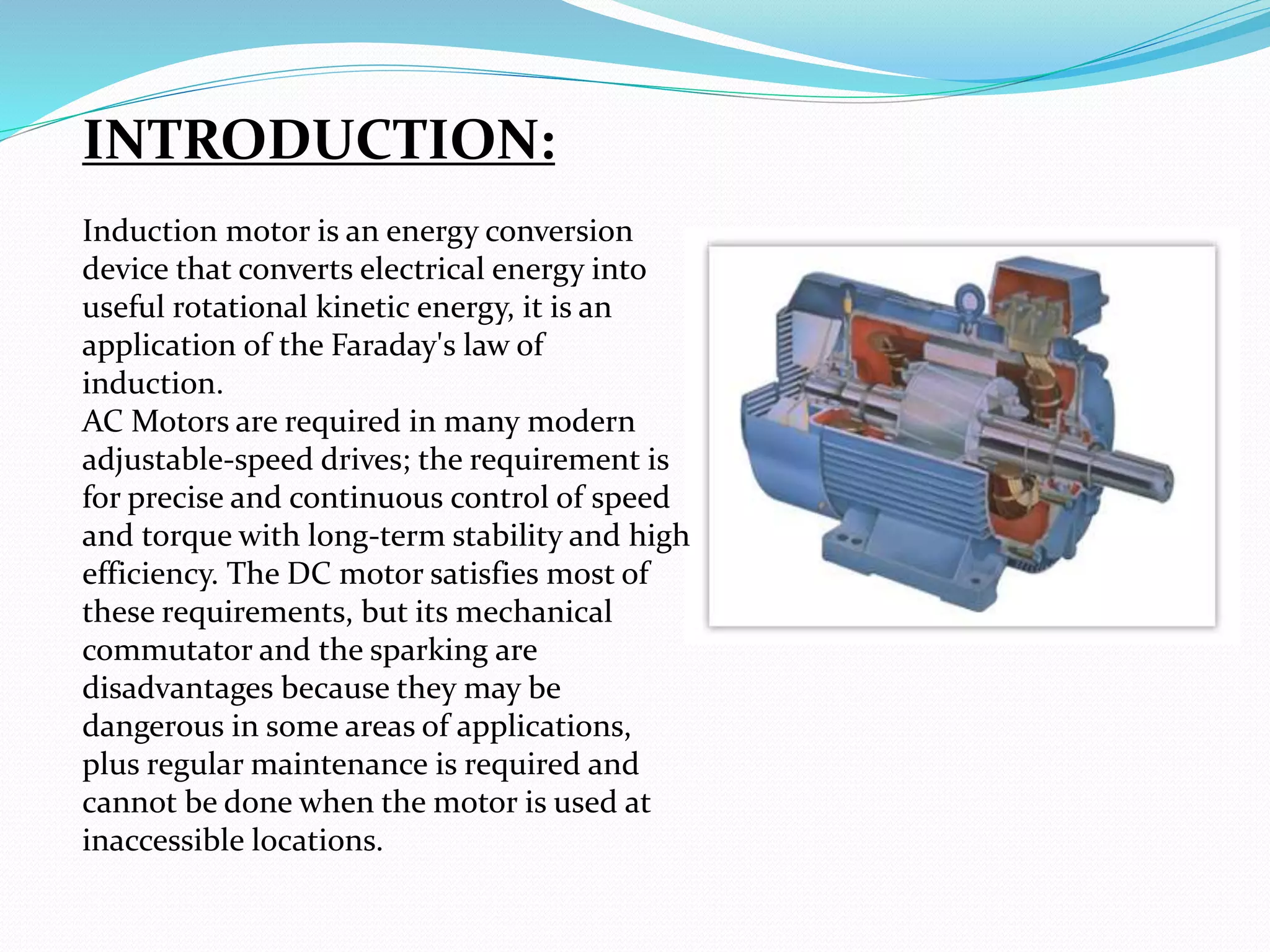

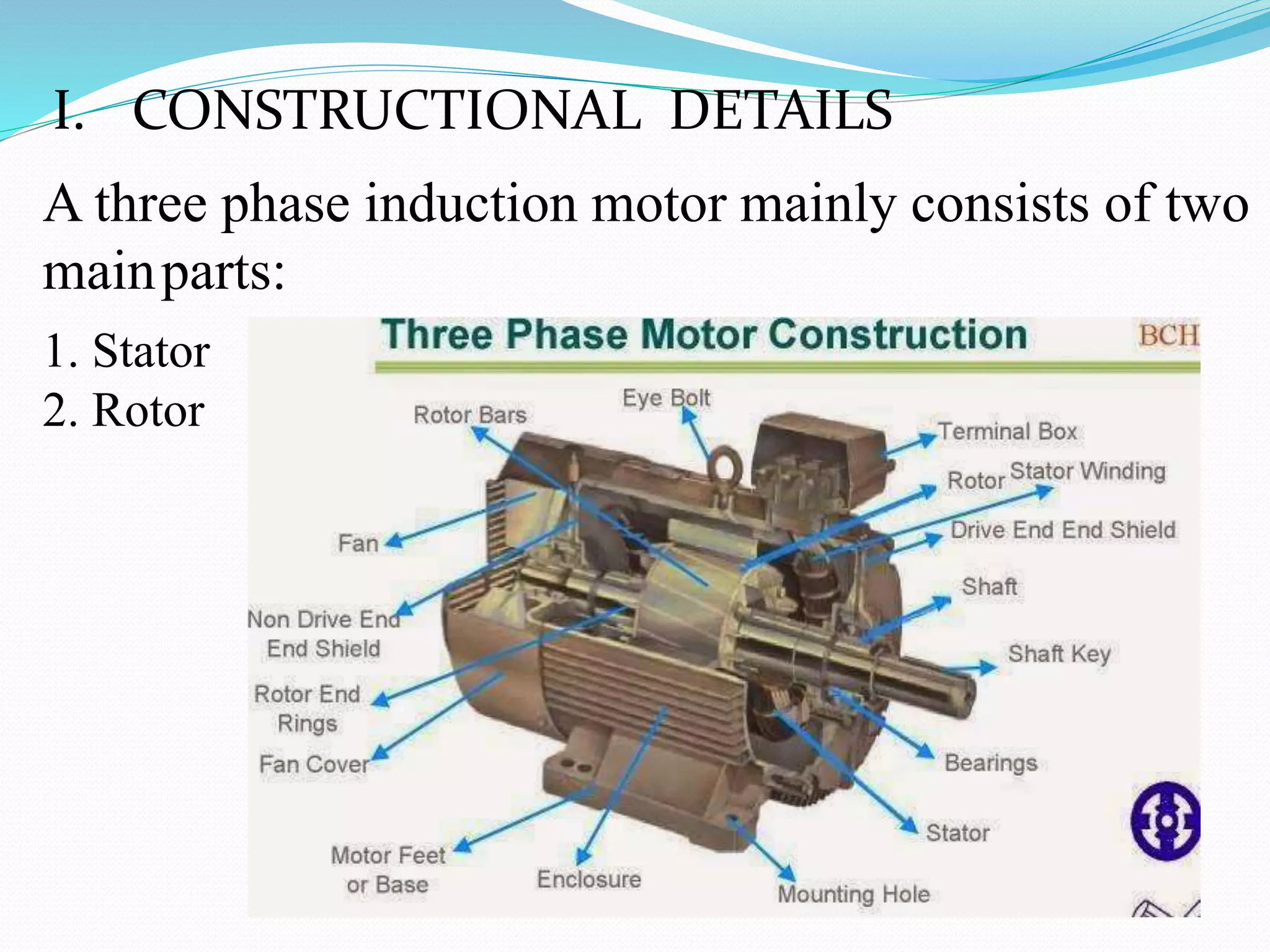

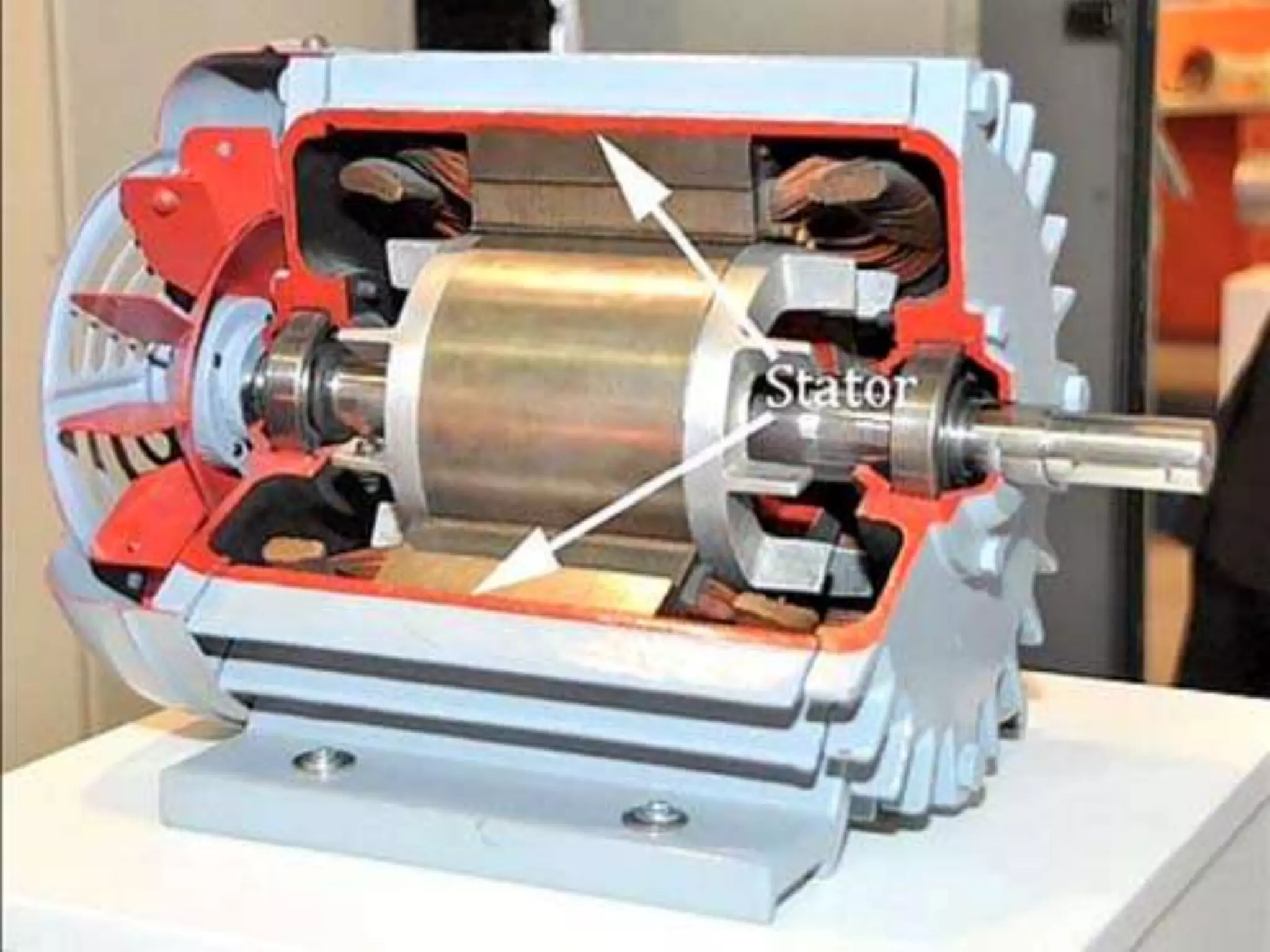

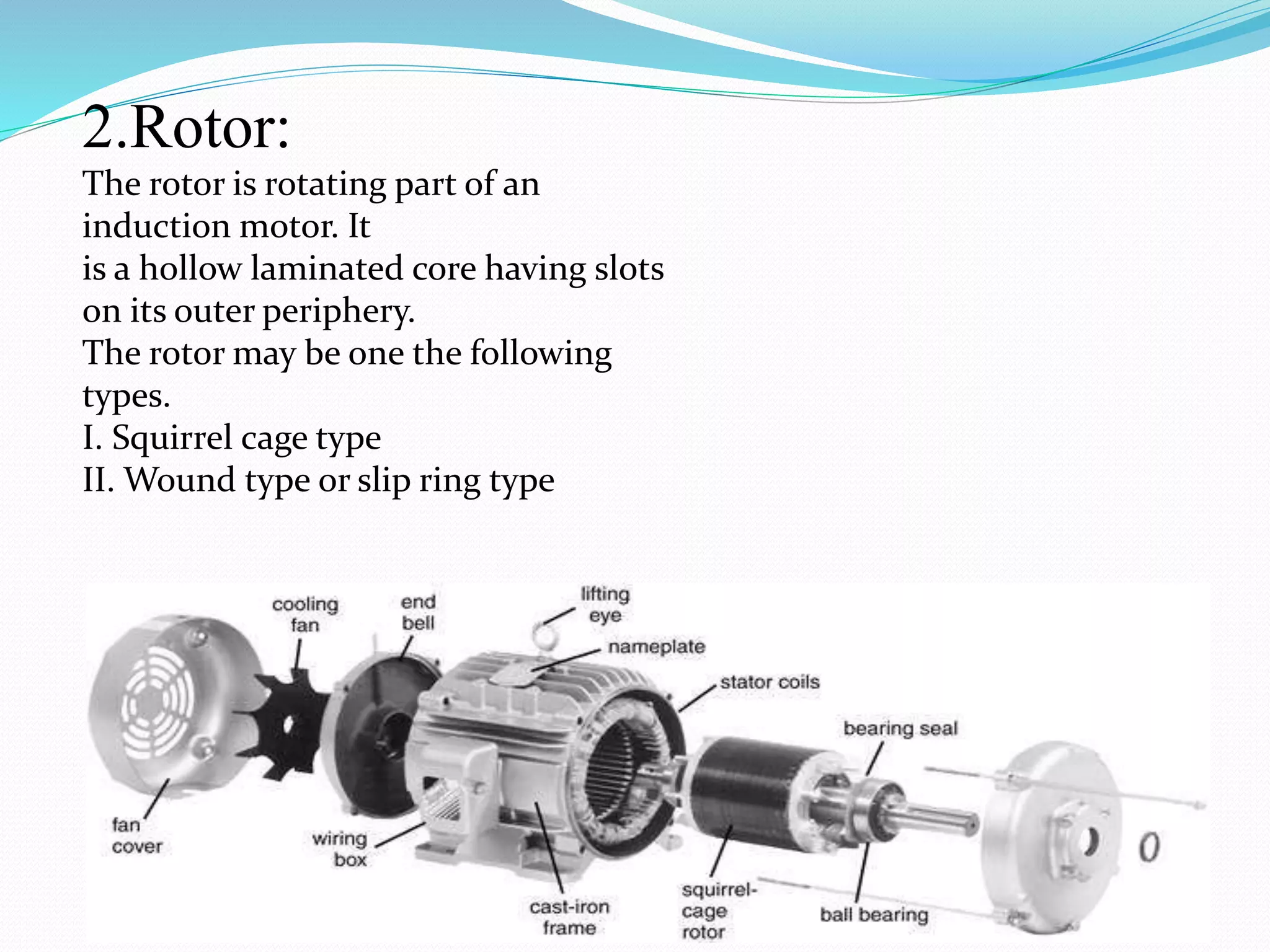

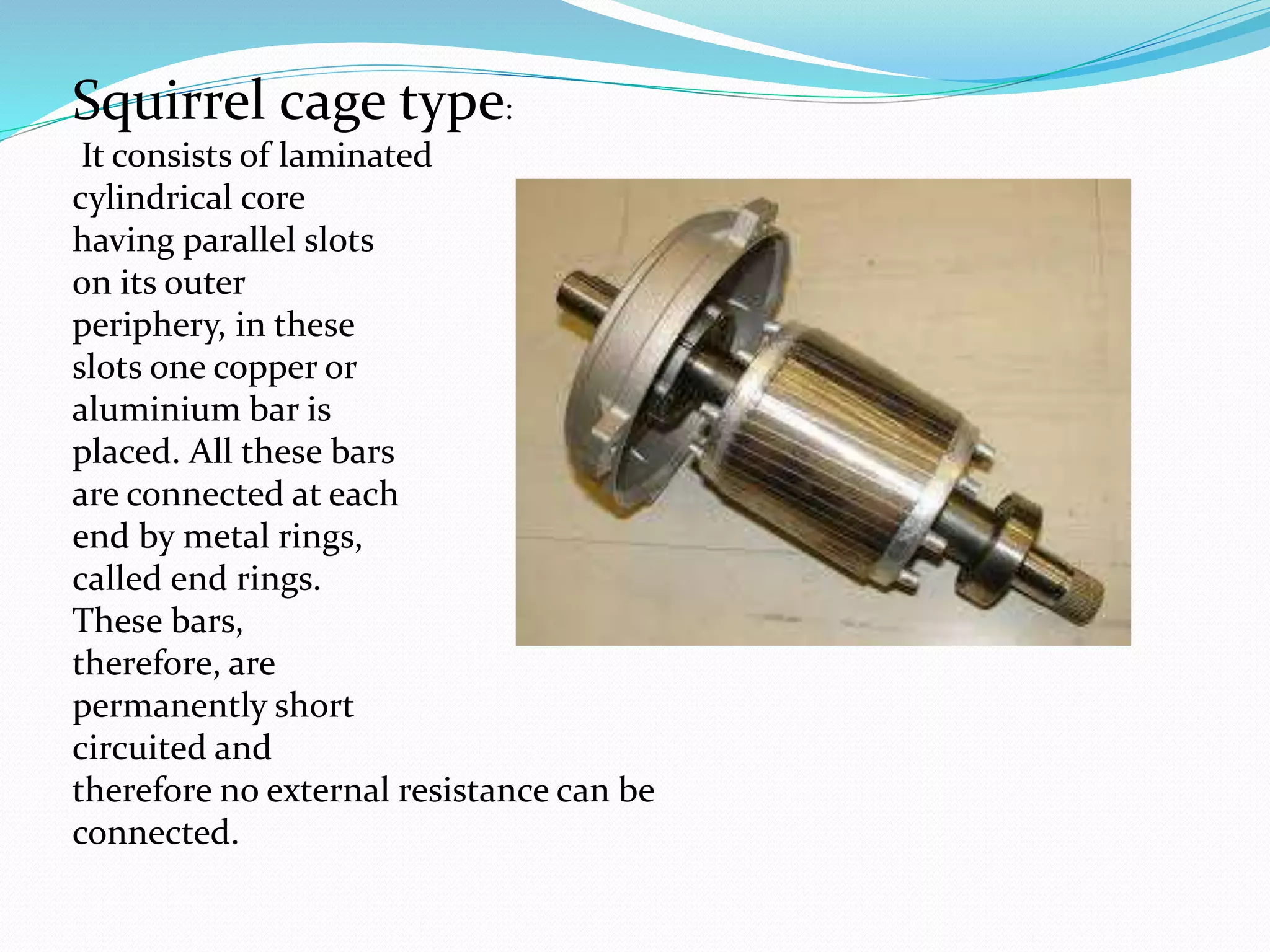

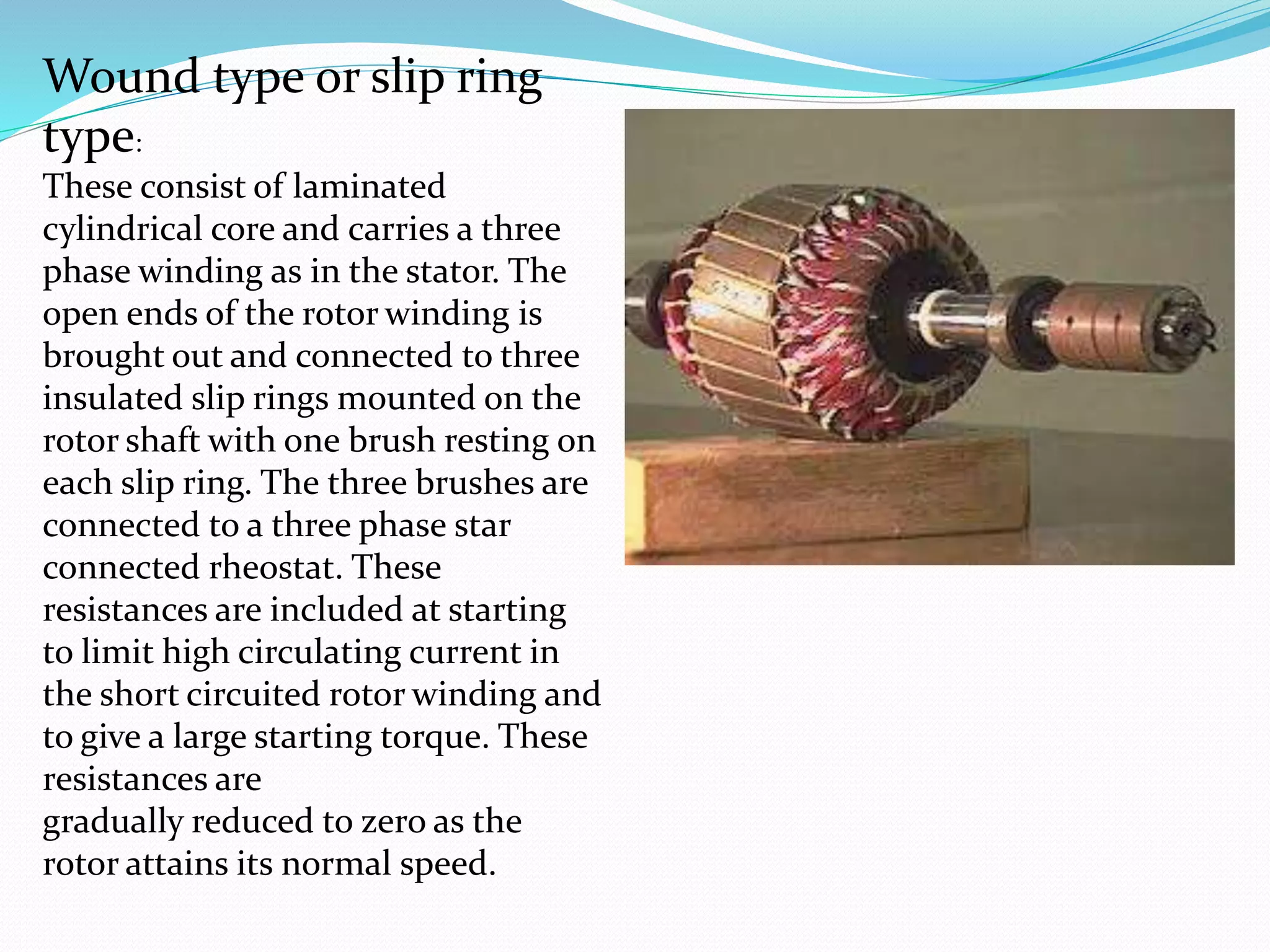

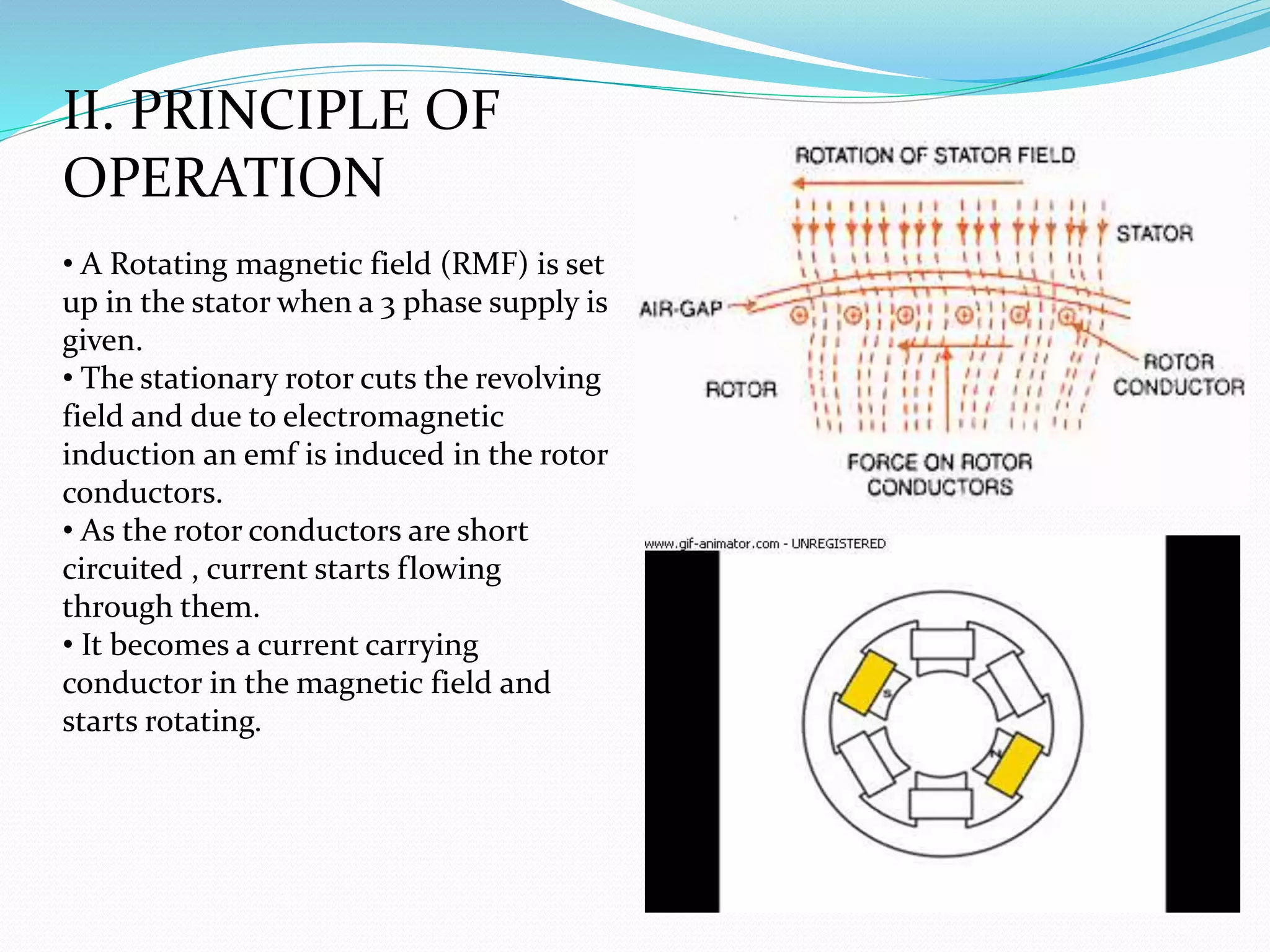

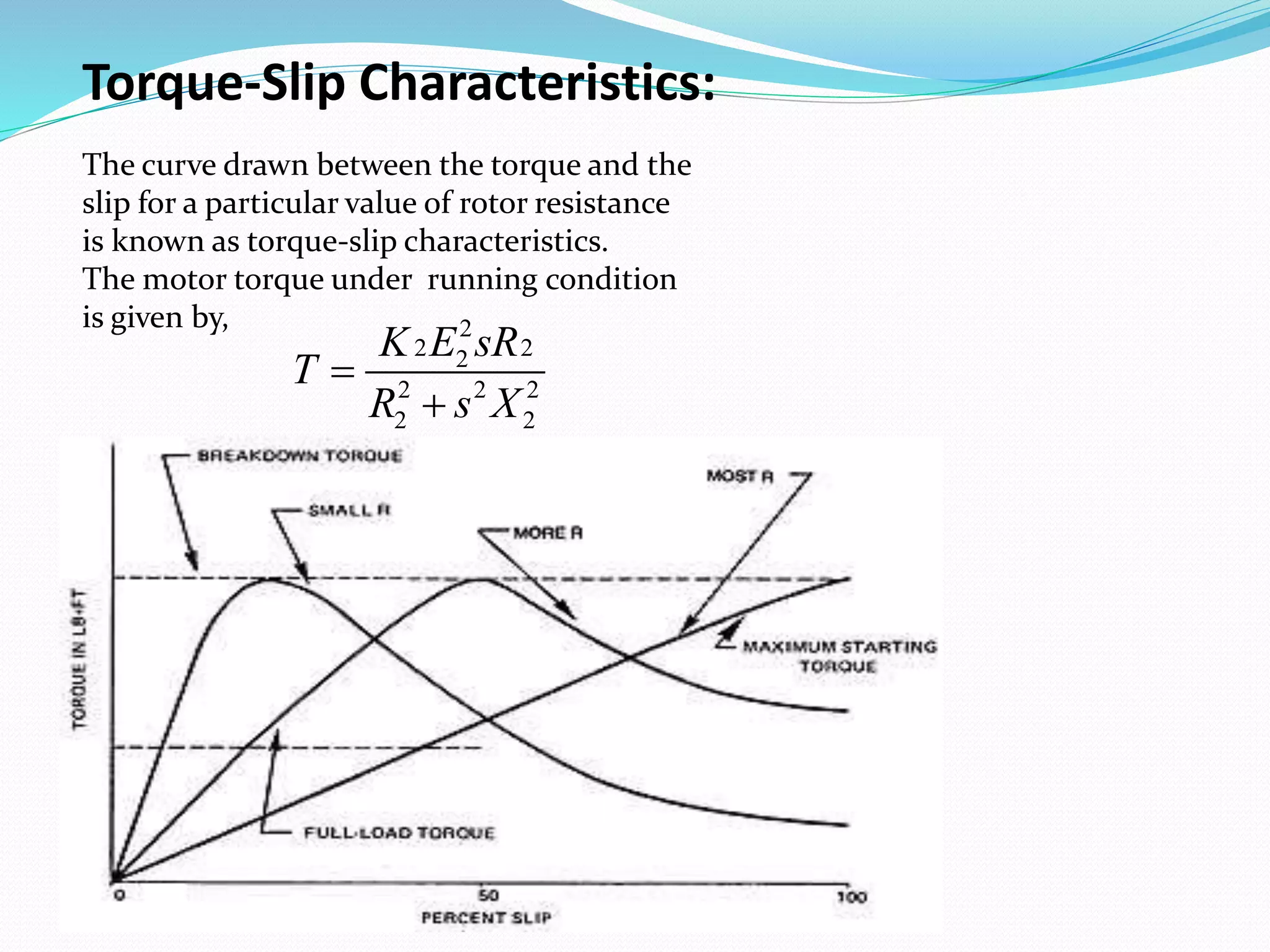

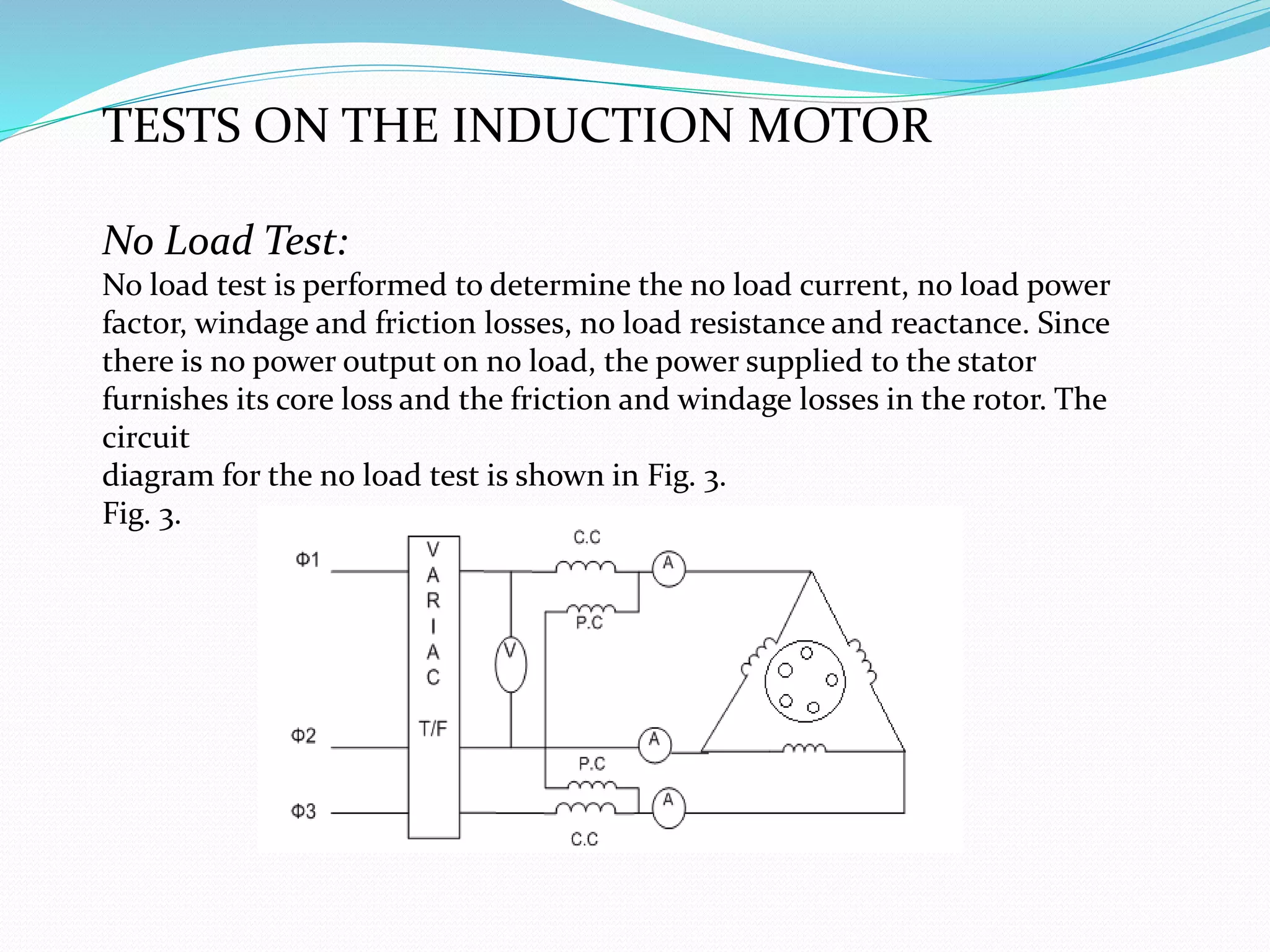

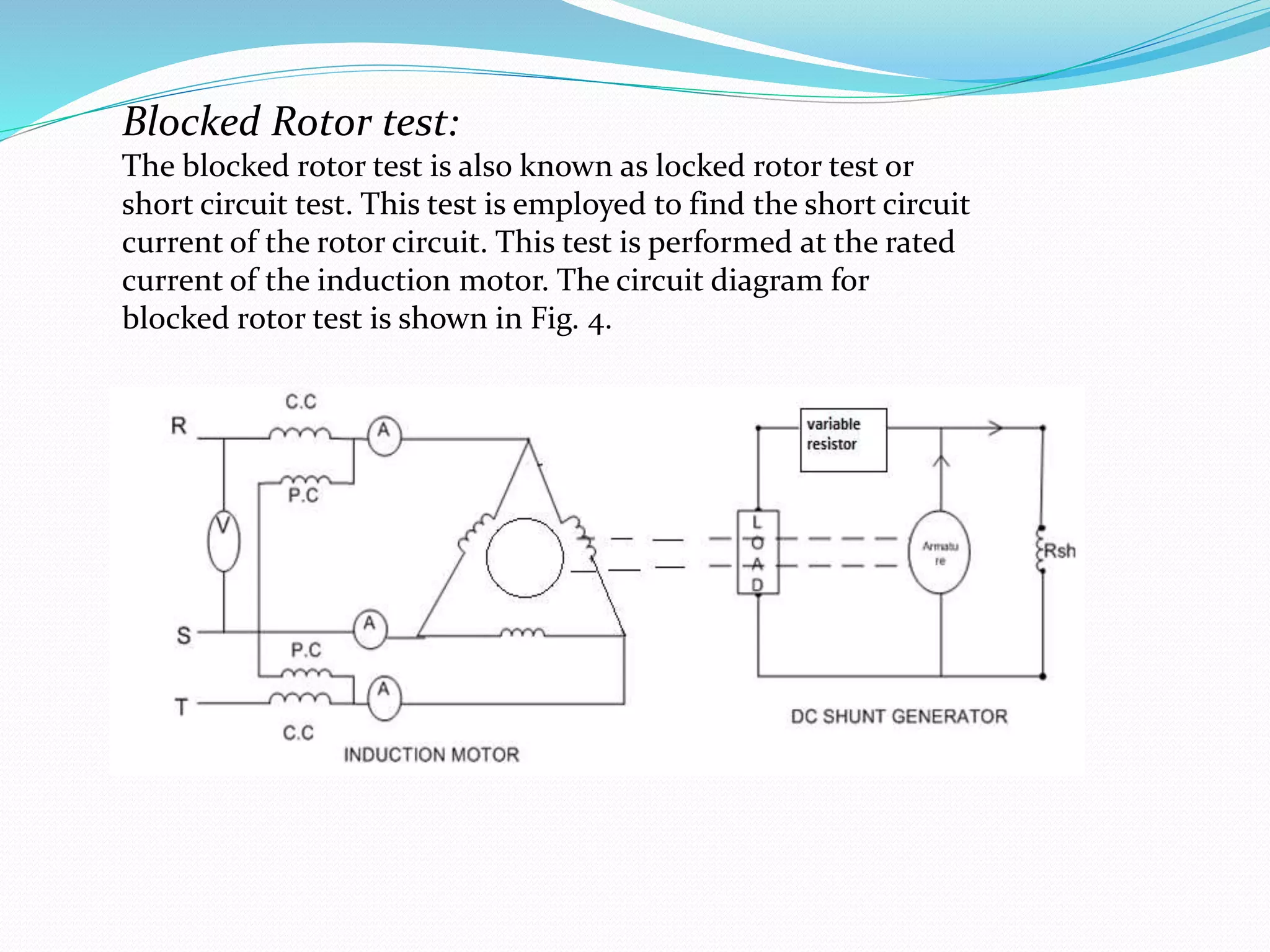

The document provides an overview of induction motors, detailing their construction, principles of operation, torque-slip characteristics, and testing methods. It emphasizes the advantages of induction motors over DC motors, such as lower maintenance and safety in hazardous locations, as well as methods for speed control. Key components include the stator and rotor, and tests include no load and blocked rotor tests to determine performance metrics.