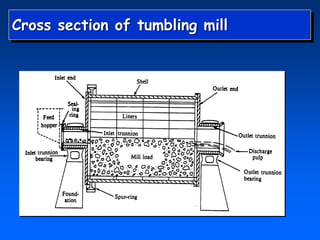

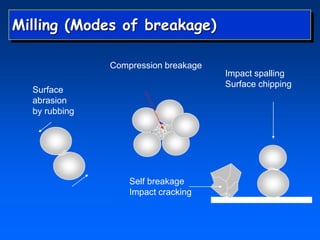

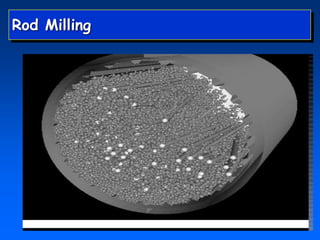

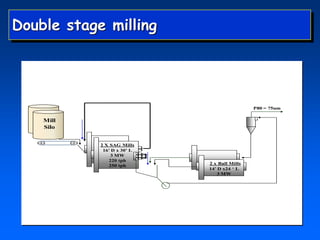

The document outlines the principles of mineral processing 4.0, focusing on grinding operations and the various types of milling, including ball mills and autogenous milling. It discusses the factors influencing milling performance such as charge volume, critical mill speed, and the properties of the feed material. Additionally, it highlights the operational aspects of closed-circuit grinding and its benefits in preventing over-grinding and increasing throughput.