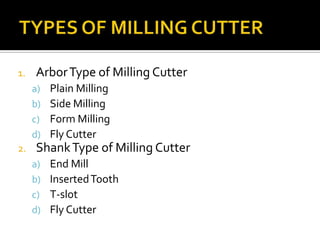

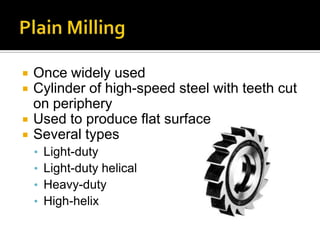

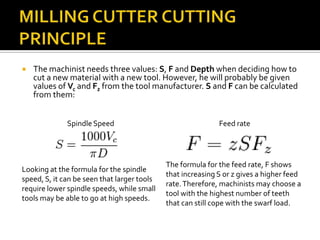

Milling cutters are cutting tools used to remove material from workpieces in milling machines. They have cutting edges and flutes to remove chips of material. Common milling cutter types include end mills, face mills, and inserted tooth cutters. Milling cutters come in various geometries and are made of materials like high-speed steel or carbide depending on the application. Cutting parameters like spindle speed, feed rate, depth of cut, and surface cutting speed determine how efficiently a milling cutter removes material from a workpiece.