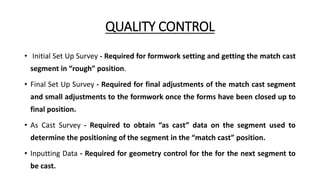

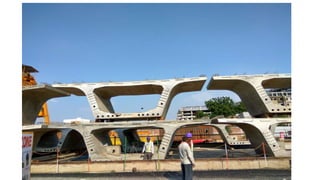

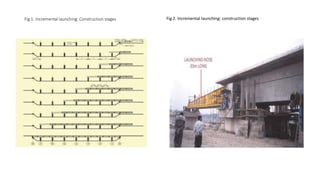

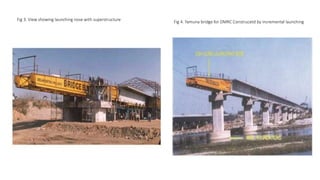

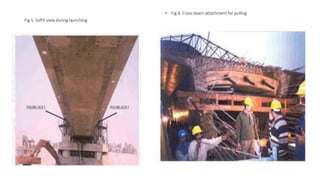

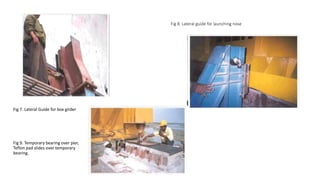

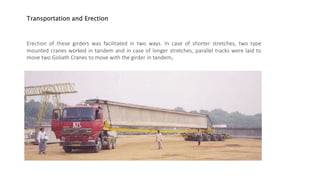

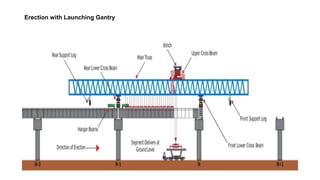

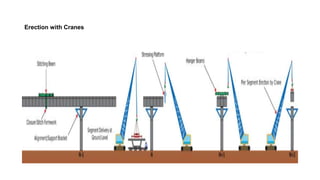

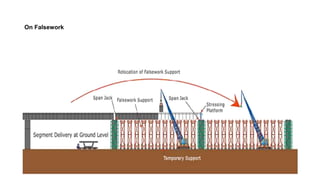

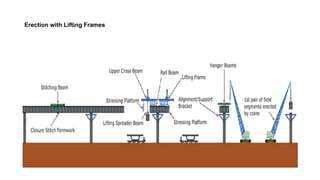

This document discusses infrastructure construction technologies used for elevated metro rail and road projects in India. It describes the use of segmental casting and transportation methods like incremental launching for long viaduct structures. Concrete pumps, batching plants, and quality control processes for precast segment casting are outlined. Various precast segment erection techniques including the use of launching gantries, cranes, and lifting frames are also summarized. Images show examples of incremental launching of bridges and transportation of precast segments by trucks for erection.