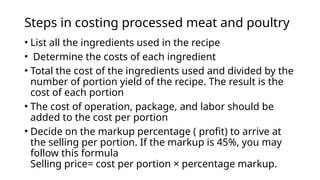

The document outlines methods for processing meat and poultry, including canning, drying, salting, and smoking, which help preserve food while preventing contamination. It also discusses the importance of packaging, highlighting various materials and their qualities that maintain food freshness and safety. Additionally, it covers steps in costing processed meat and poultry, detailing how to calculate the cost per portion and determine selling prices based on markups.