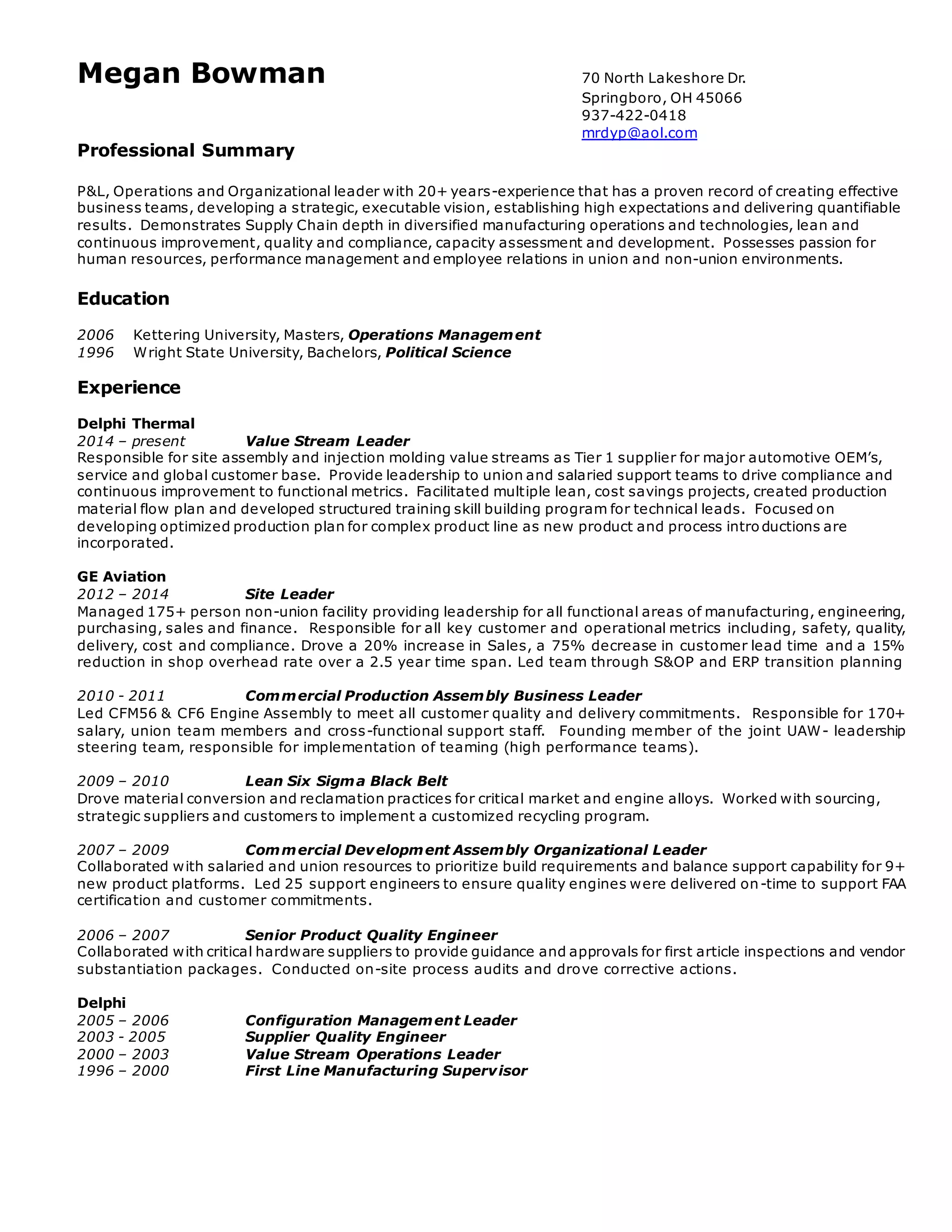

Megan Bowman has over 20 years of experience in operations leadership, P&L management, and organizational development for manufacturing companies. She holds a Master's degree in Operations Management and a Bachelor's degree in Political Science. Her experience includes value stream leadership roles at Delphi Thermal and site leadership positions at GE Aviation where she improved sales, reduced costs and lead times, and developed high performance teams. She has a proven track record of delivering results through lean initiatives, process improvements, and performance management.