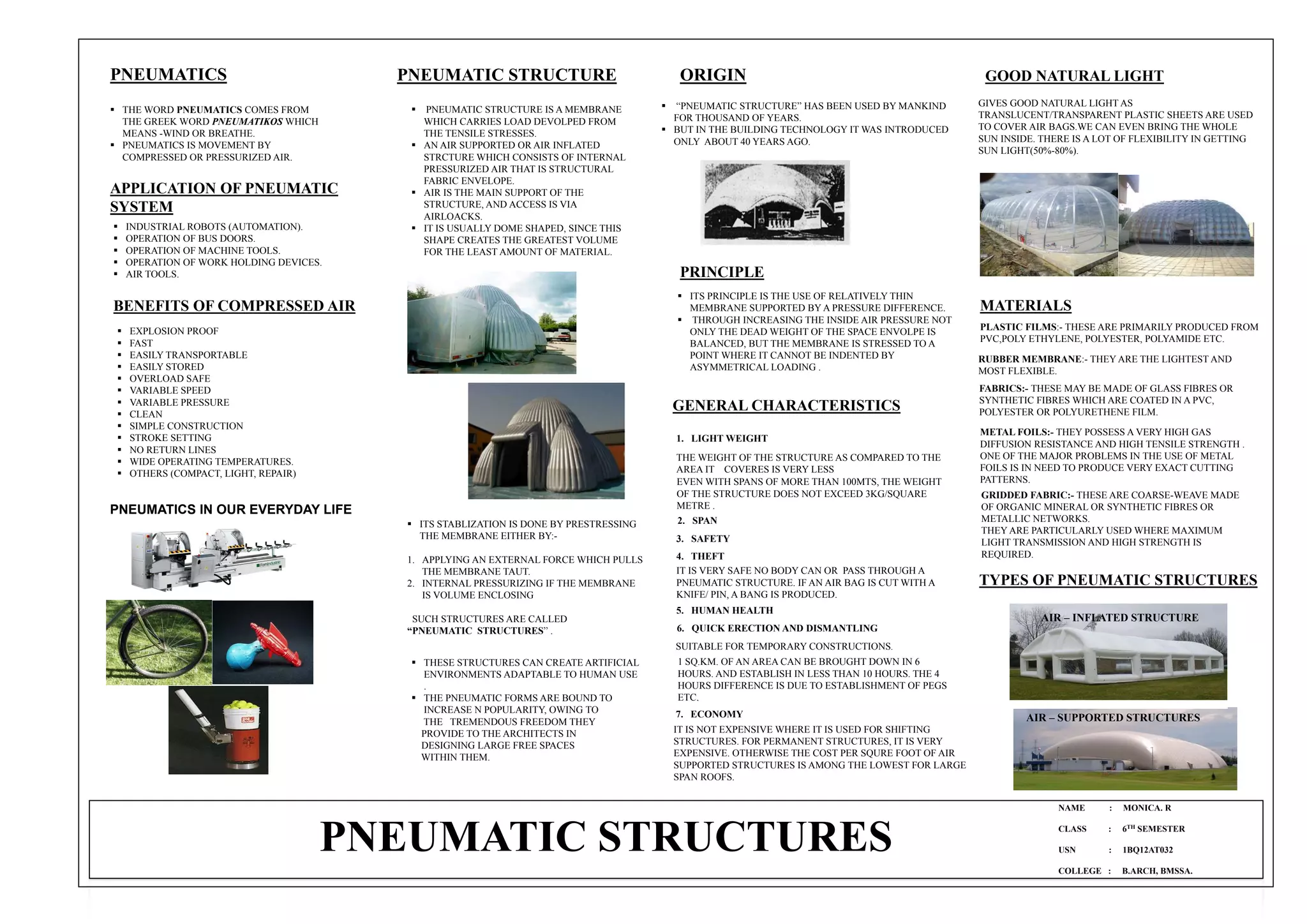

This document discusses various construction materials and techniques, primarily focusing on pneumatics, waterproofing, gypsum, plastics, cement, asbestos, rubber, and fiber-reinforced polymers. It outlines the characteristics, benefits, applications, and manufacturing processes of these materials, highlighting their relevance in modern architecture and construction. The text also emphasizes the growing popularity of pneumatic structures and the versatility of materials like gypsum board and plastics in building construction.