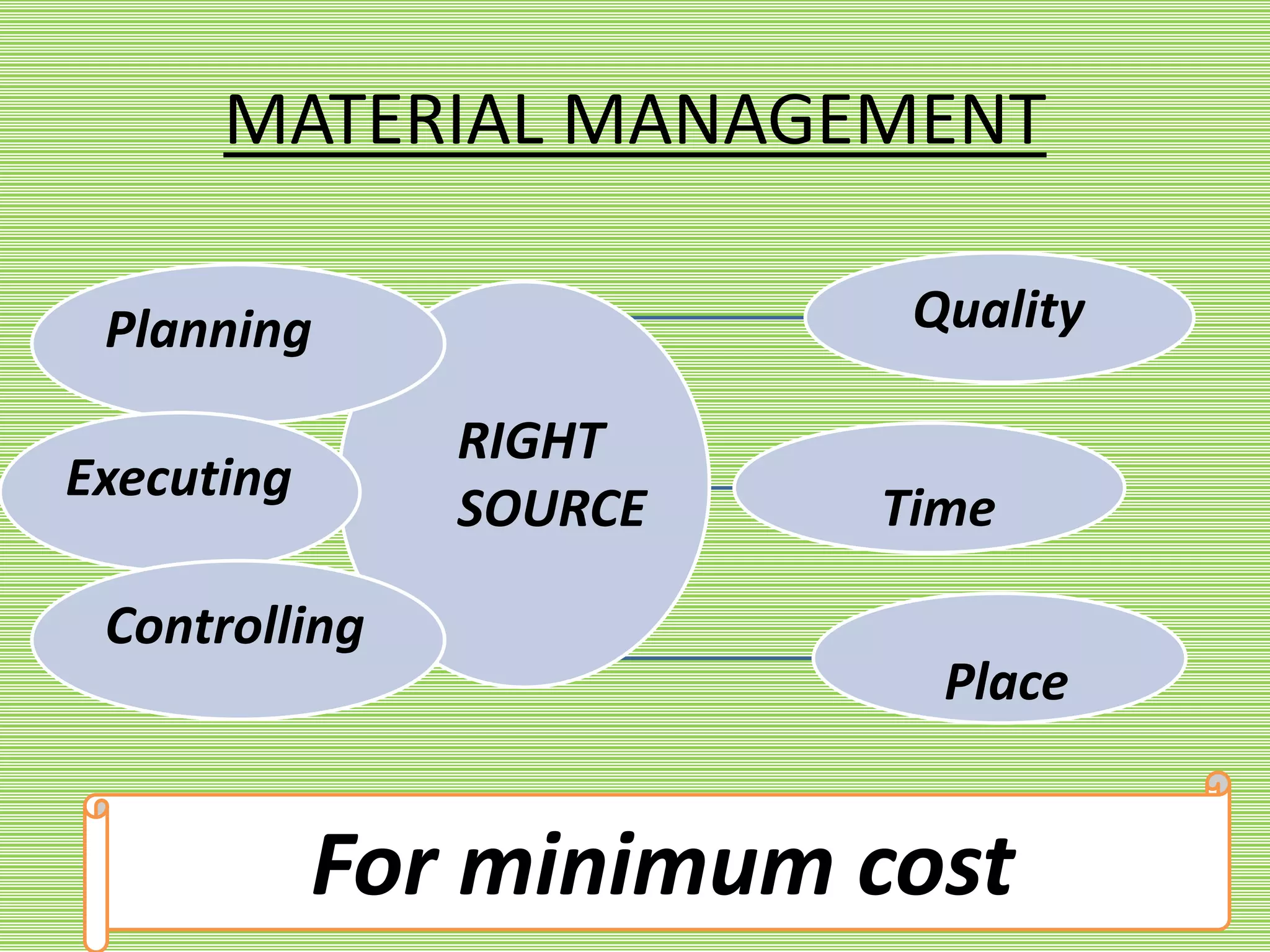

The document discusses material management in construction projects. It states that proper material management is important to control project costs. It defines material management as planning, executing, and controlling the right source, quality, time and place of materials to minimize costs. The key phases of successful material management are purchasing, storing, and usage. The document also discusses analyzing the Raviz Hills construction company's material management practices and implementing improvements like inventory controlling, analyzing purchasing procedures, procurement and tracking, and costs using ABC analysis and FIFO methods. The case study helped identify new theories to properly manage materials at construction sites.