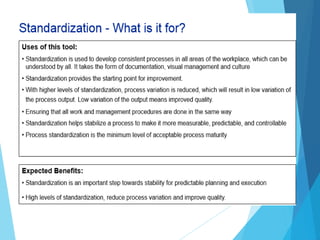

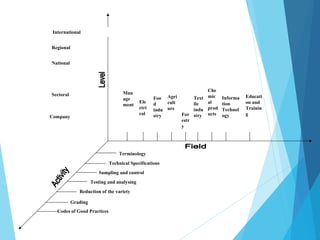

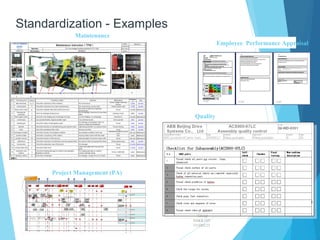

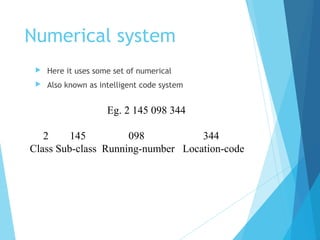

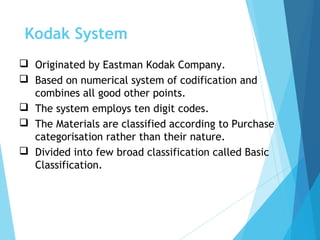

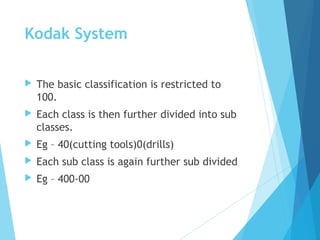

Standardization aims to achieve optimum order and efficiency through activities that provide repetitive solutions in science, technology and economics, with objectives including reducing costs, improving quality, and increasing productivity. Codification systematically represents items in an industry using abbreviated codes for identification, classification, and organization. Common methods for codification include alphanumeric, numerical, color-based, and classification-based systems that uniquely and concisely identify items for efficient inventory management and procurement.