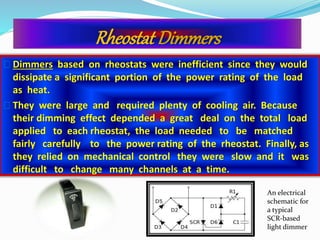

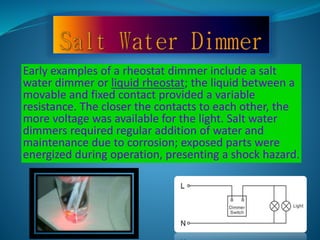

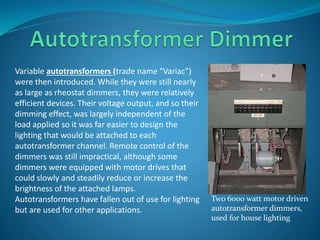

Dimmers are devices used to vary the brightness of lights by changing the voltage waveform applied. Early dimmers used inefficient variable resistors or rheostats, but modern dimmers use silicon-controlled rectifiers for higher efficiency. Dimmers are used both in domestic and professional lighting installations, with professional dimmers often controlled digitally via protocols like DMX. Key developments included the first solid-state dimmer by Joel Spira and the introduction of thyristor dimmers which enabled remote analog control.