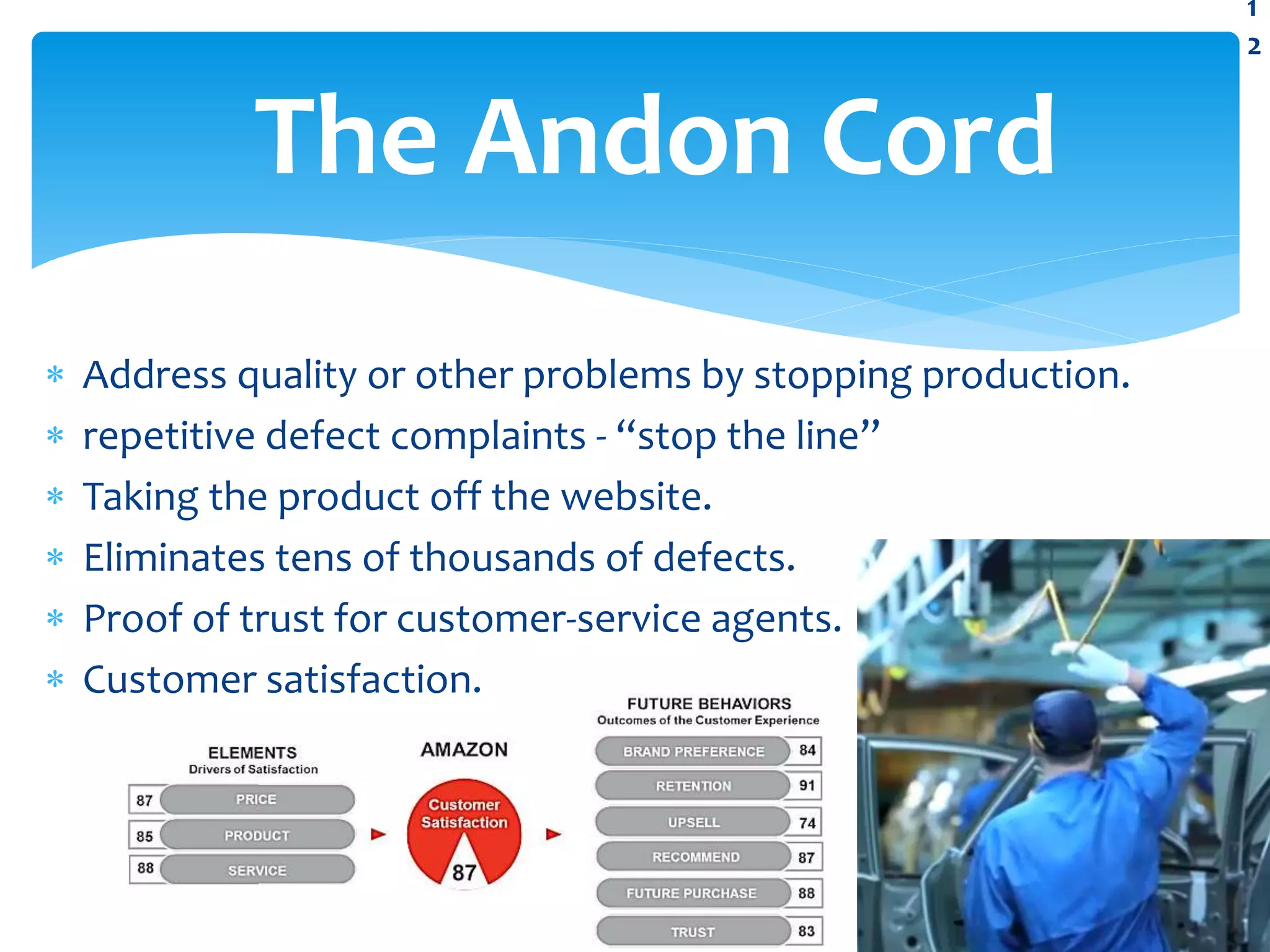

Lean management focuses on eliminating waste while ensuring quality. It has been applied successfully in various industries like banking, healthcare, airlines, and restaurants by streamlining processes. At Amazon, lean principles have been implemented since its inception through practices like kaizen workshops, use of the andon cord to stop production when issues are detected, and applying lean to software development and 3D printing. The next frontiers for lean include bringing its principles to more complex software development and using technologies like 3D printing for on-demand manufacturing.