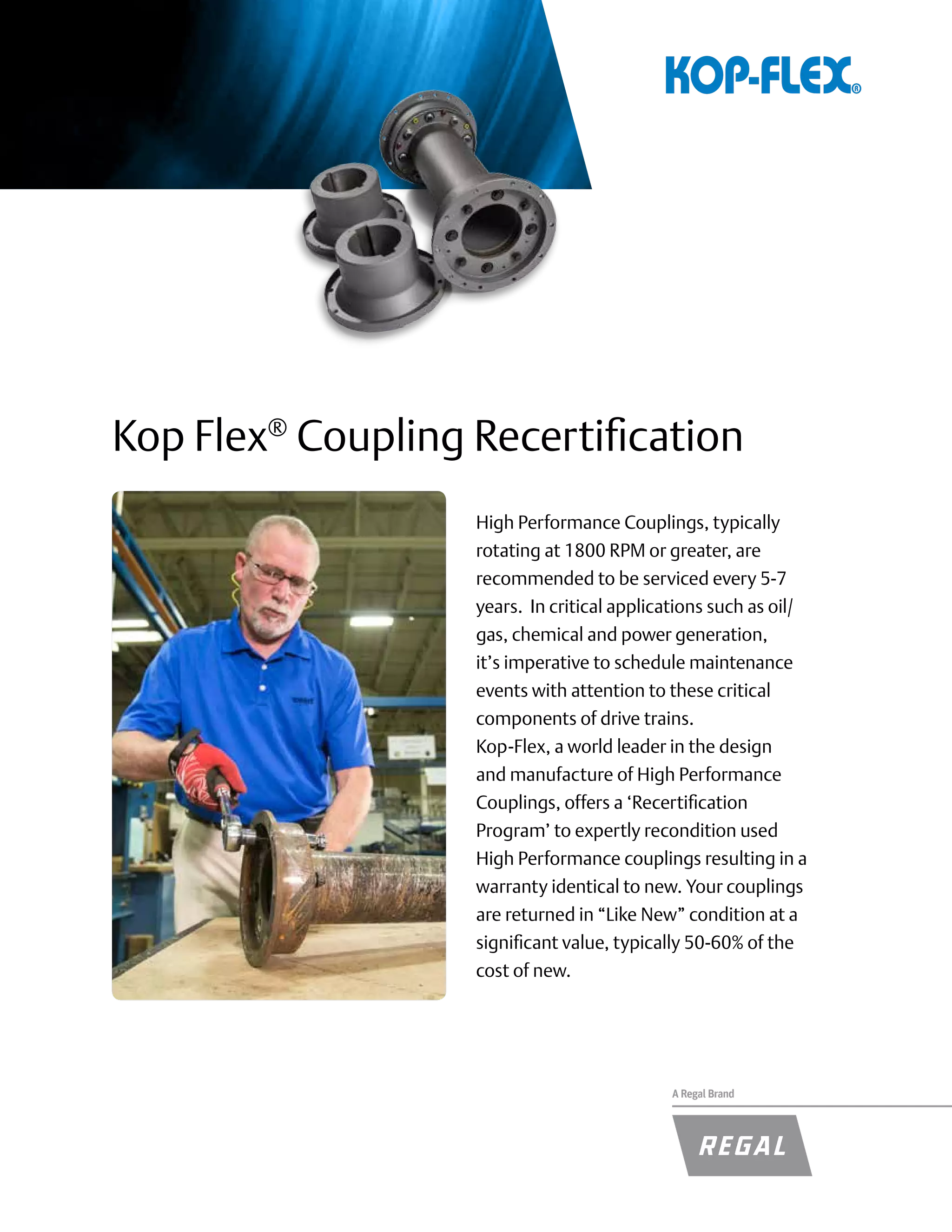

High Performance Couplings used in critical applications like oil, gas, and power generation should be serviced every 5-7 years due to rotating at high speeds of 1800 RPM or greater. Kop-Flex, a world leader in coupling design, offers a recertification program to recondition used couplings to like-new condition through expert refurbishing and testing, providing the same warranty as a new coupling at 50-60% of the cost. The recertification process includes comprehensive mechanical and metallurgical evaluation, updating to current standards, cleaning, replacing parts like flexible elements and hardware, re-balancing, and custom packaging for protection.