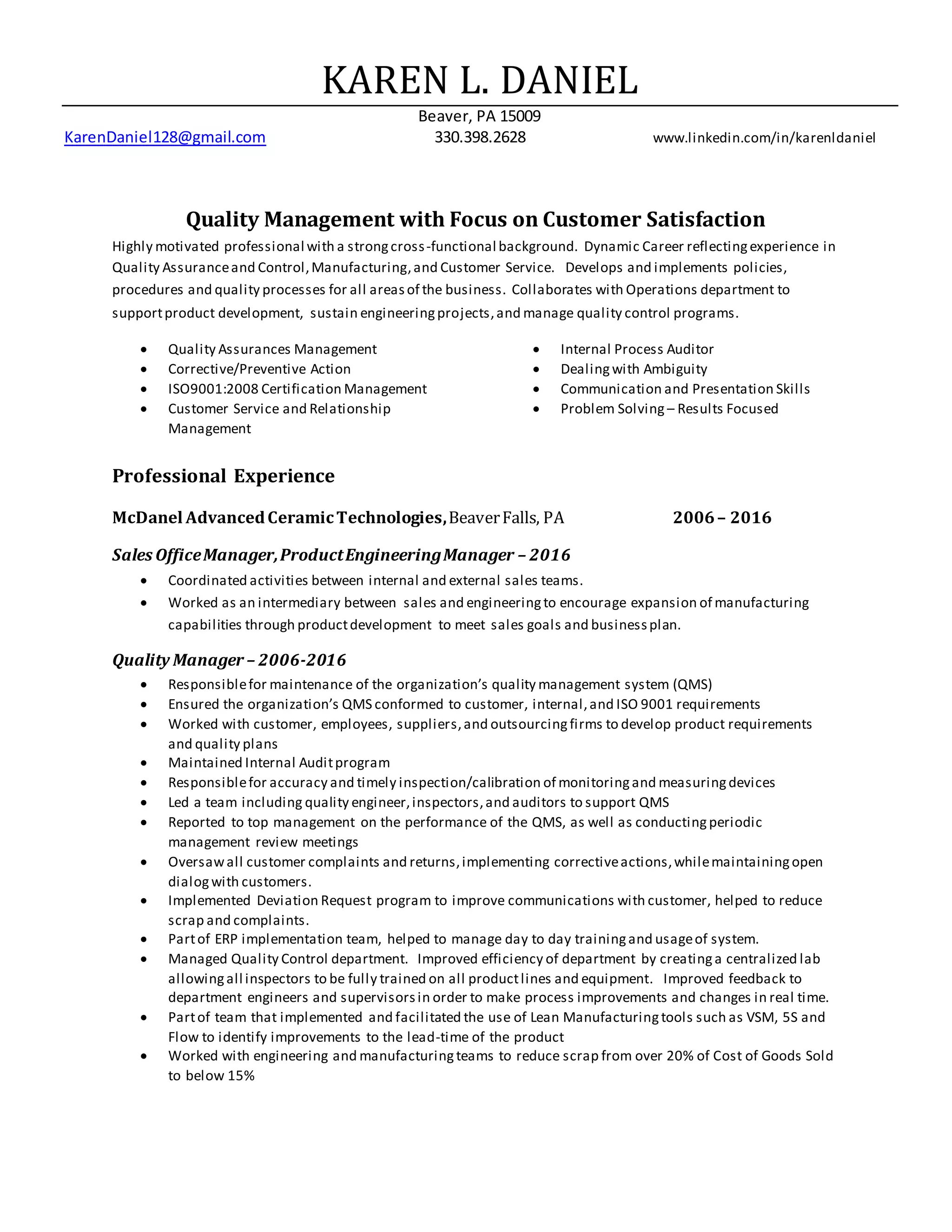

The document is a resume for Karen L. Daniel outlining her experience in quality management, manufacturing, and customer service roles over 10 years at McDanel Advanced Ceramic Technologies, where she held positions including Quality Manager, Sales Office Manager, Product Engineering Manager, and Interim Manufacturing Manager, and was responsible for quality assurance, ISO certification, process improvement, and reducing customer complaints. Her background includes a B.S. in Ceramic Engineering and project management and lean manufacturing training.