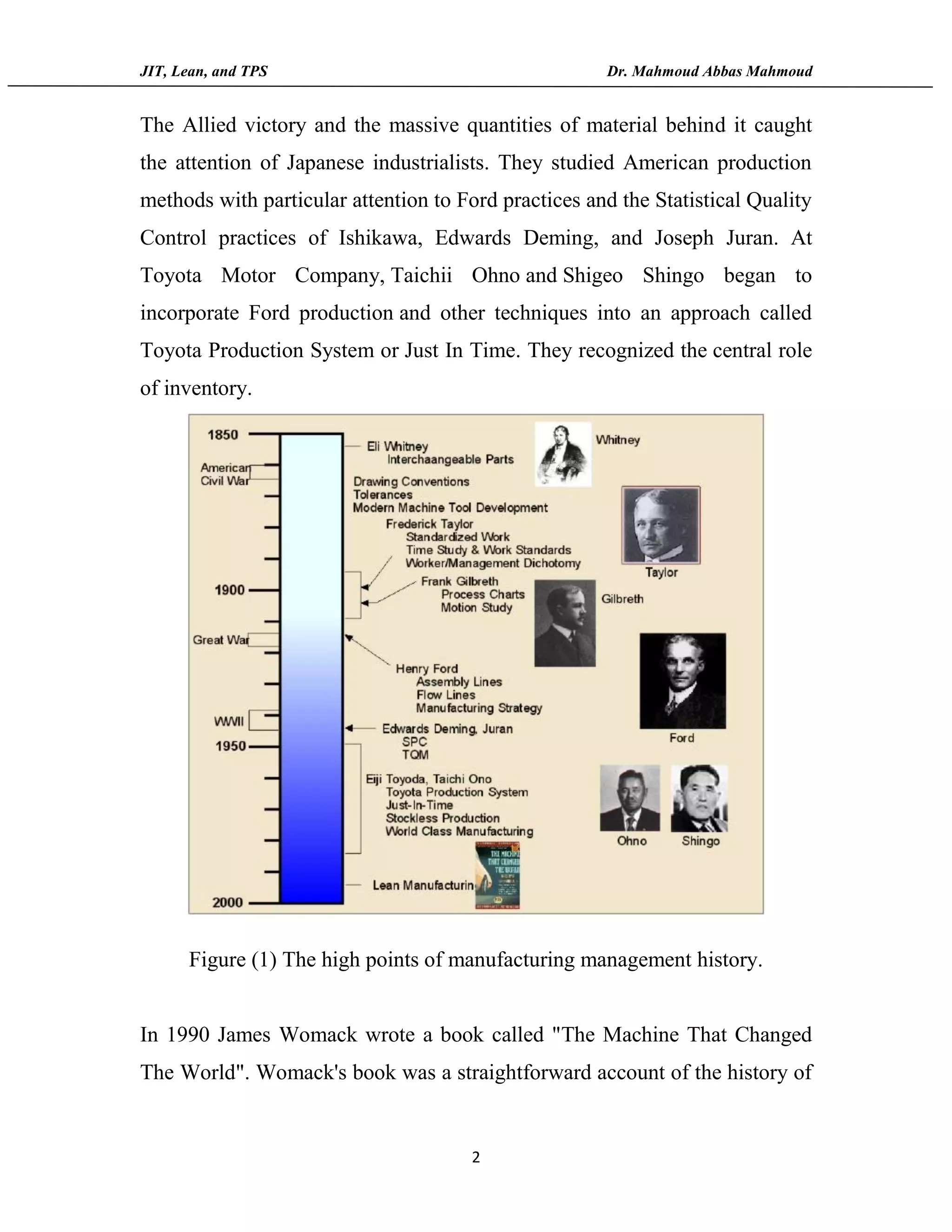

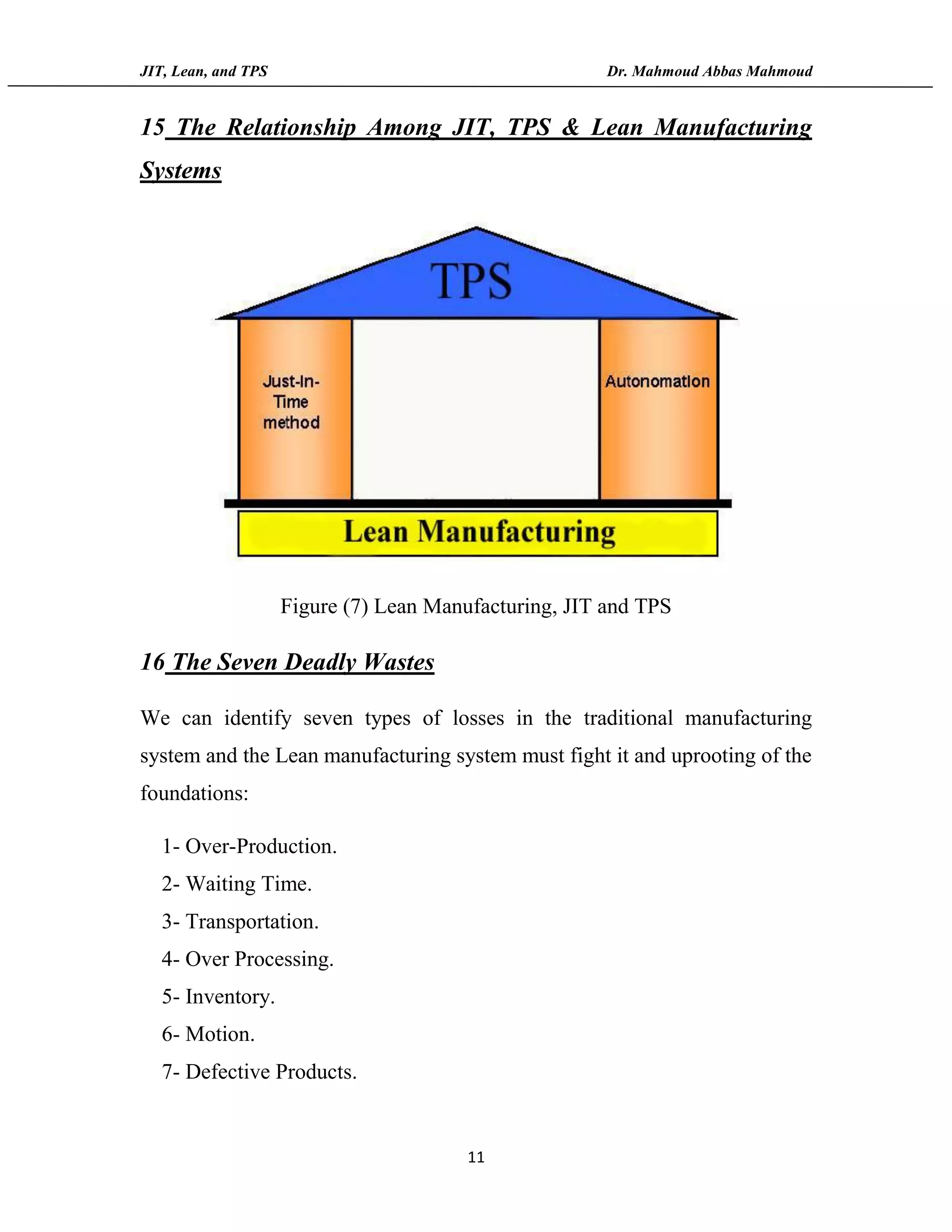

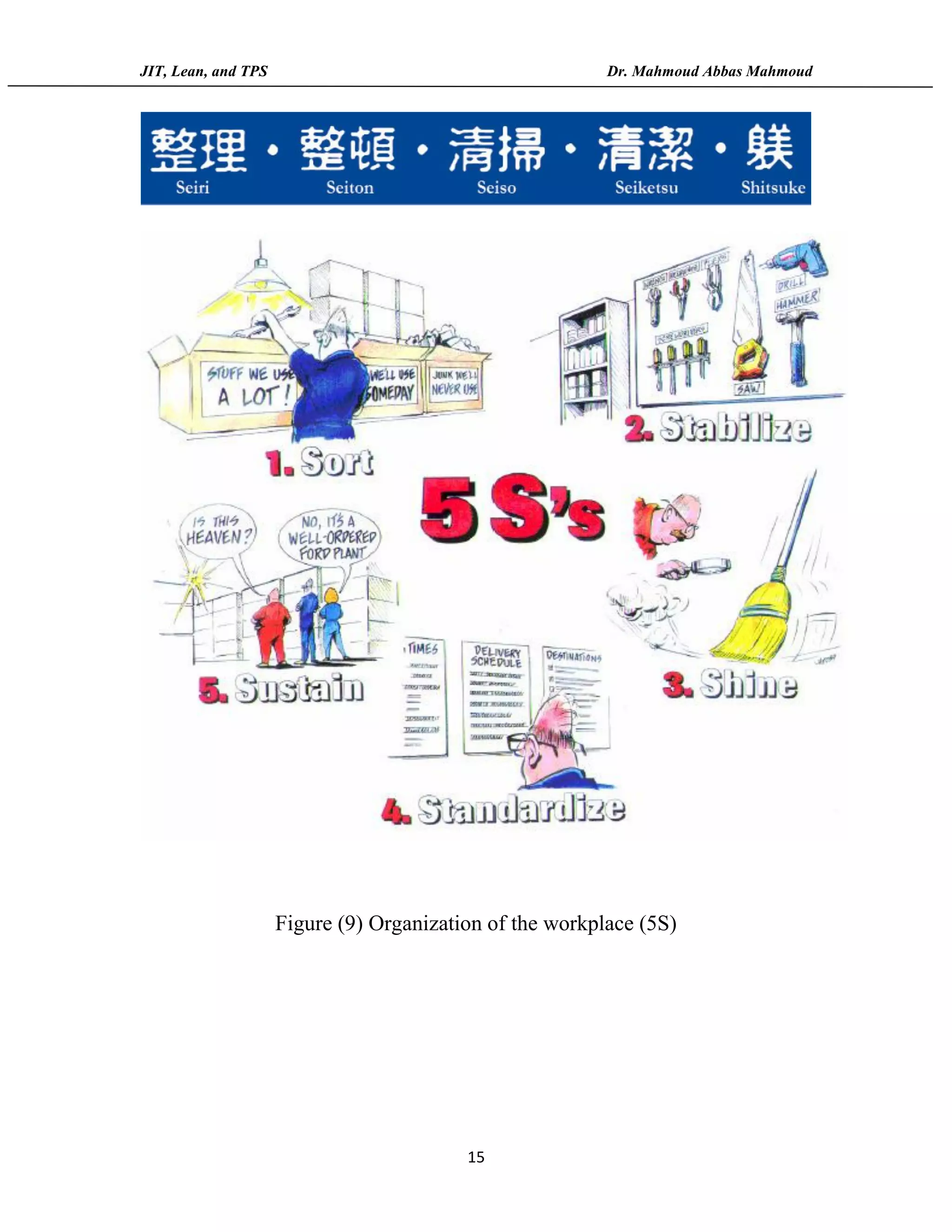

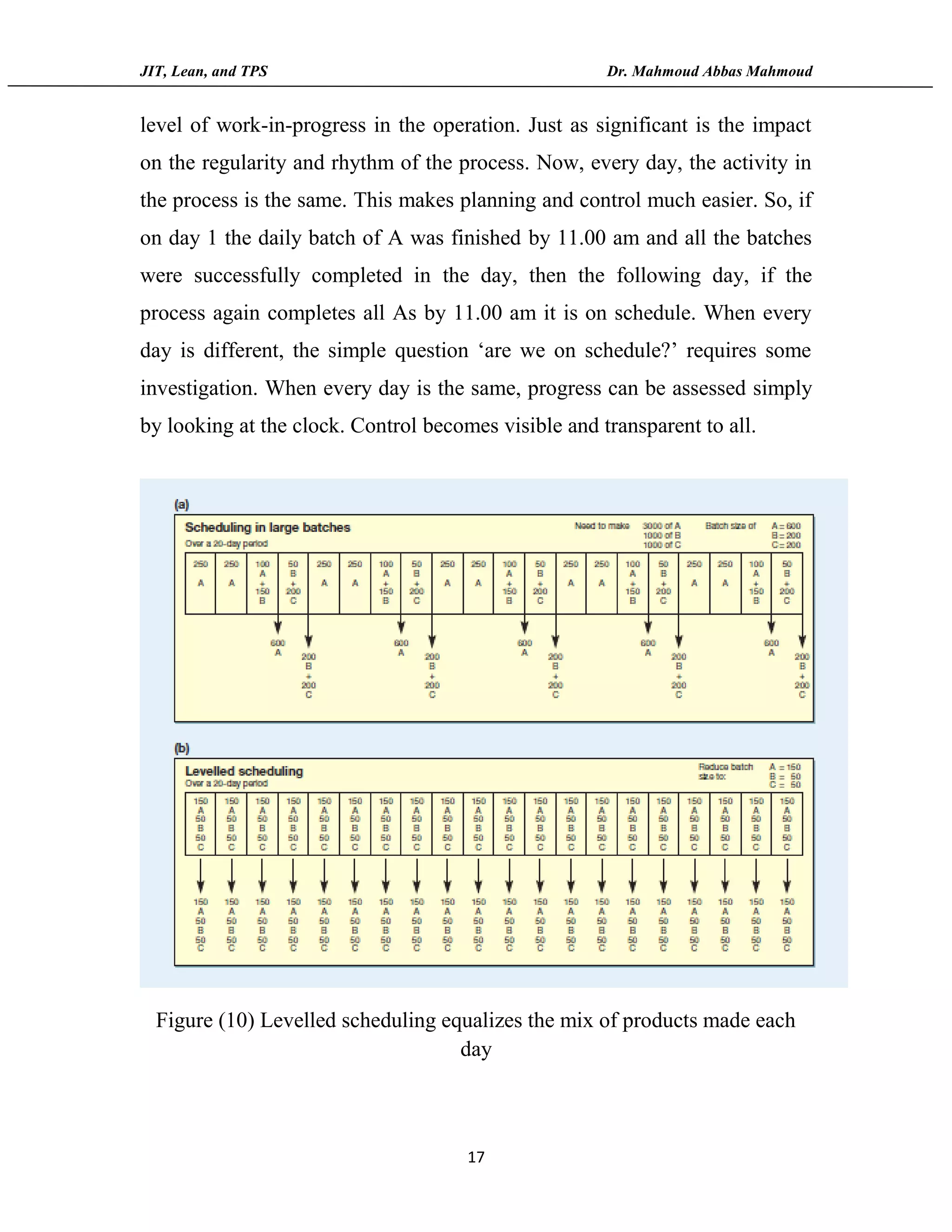

This document discusses Just-in-Time (JIT) manufacturing, Lean manufacturing, and the Toyota Production System (TPS). It provides a history of manufacturing management approaches and describes Push and Pull systems. Key aspects of JIT include using kanban cards to signal production needs and leveling production schedules. Lean aims to eliminate waste using tools like total productive maintenance and 5S. TPS principles emphasize continuous improvement, problem solving, and respect for employees. The document explores the relationships between these systems and their goals of optimizing production flow.