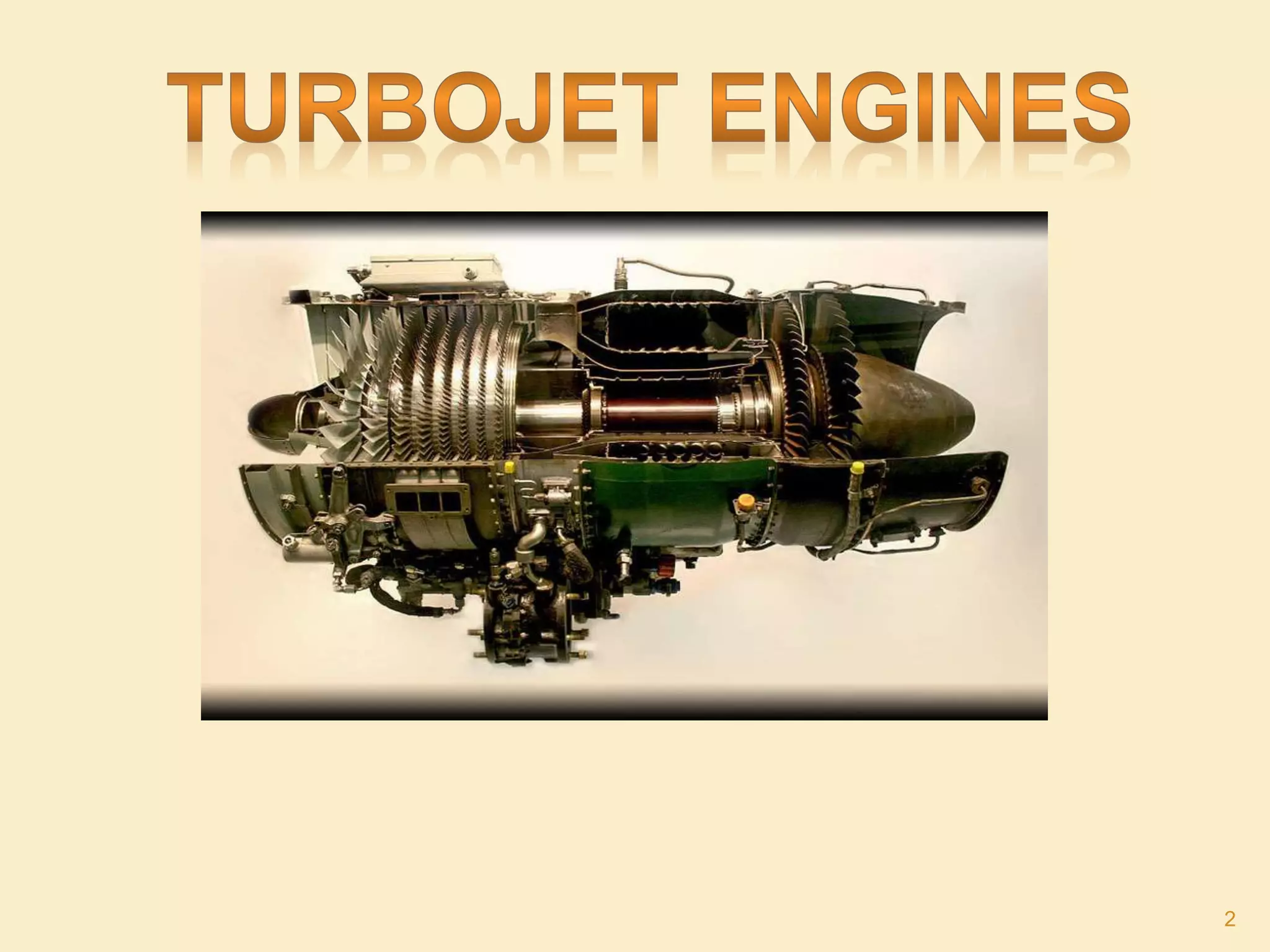

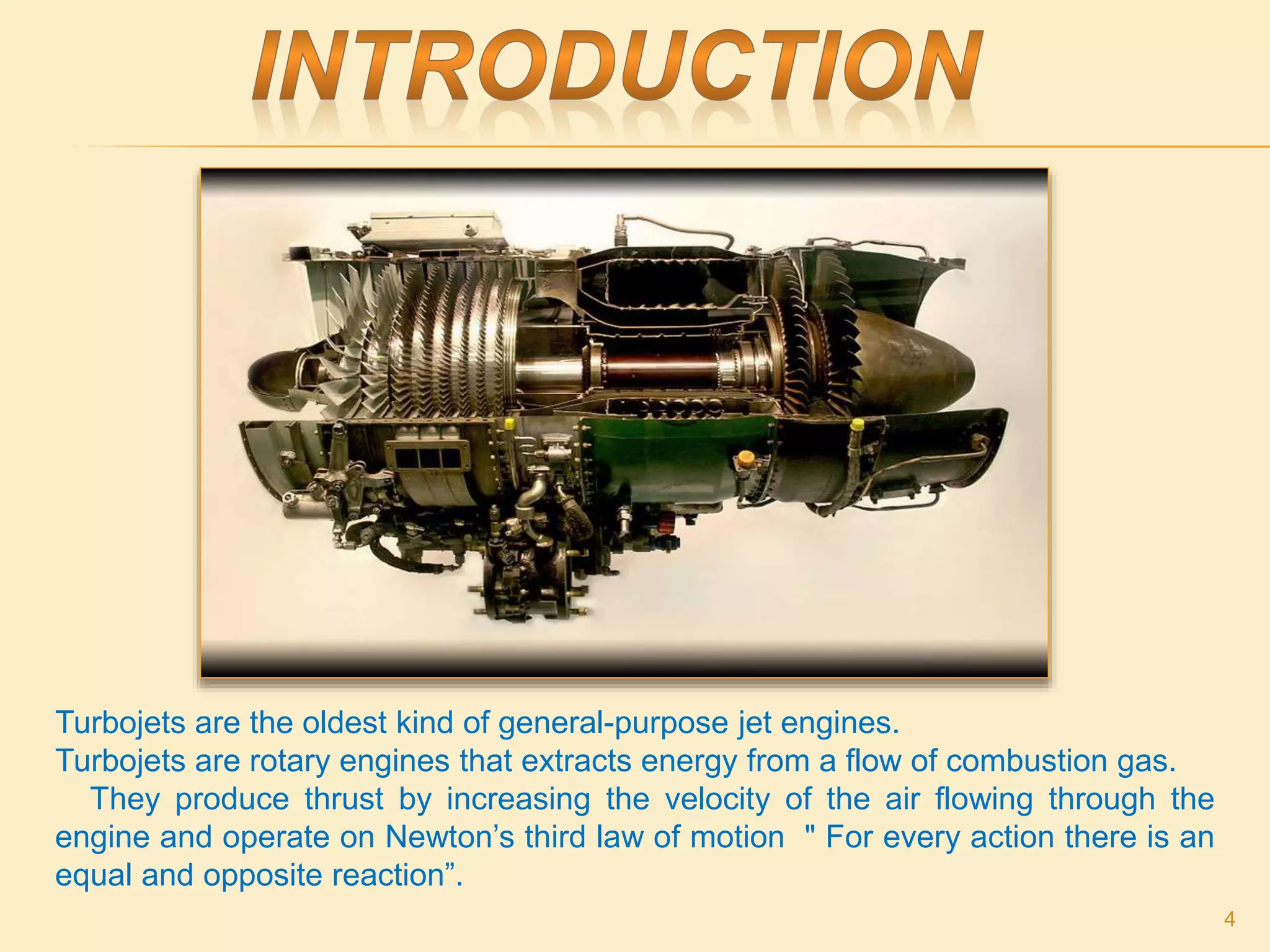

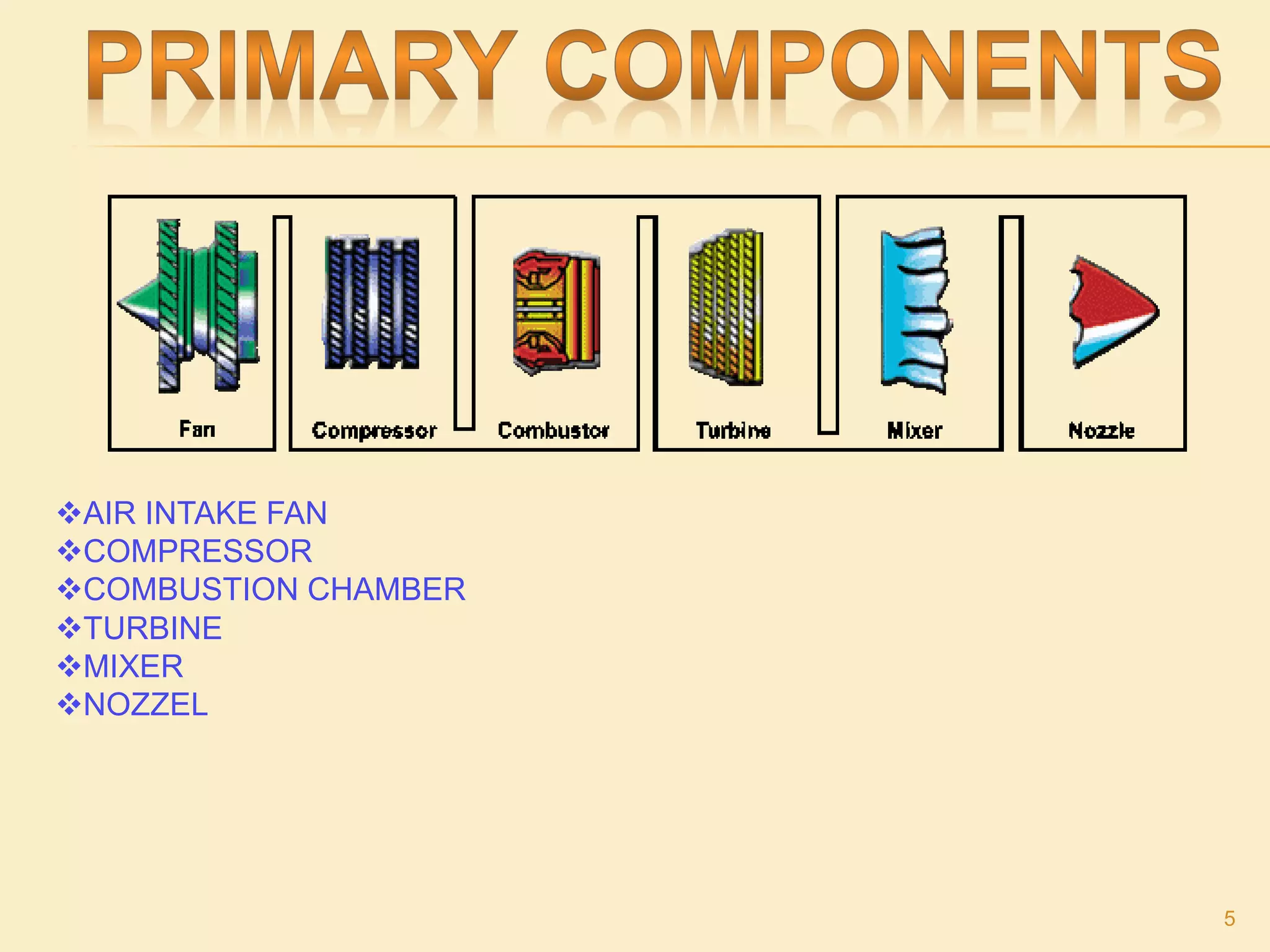

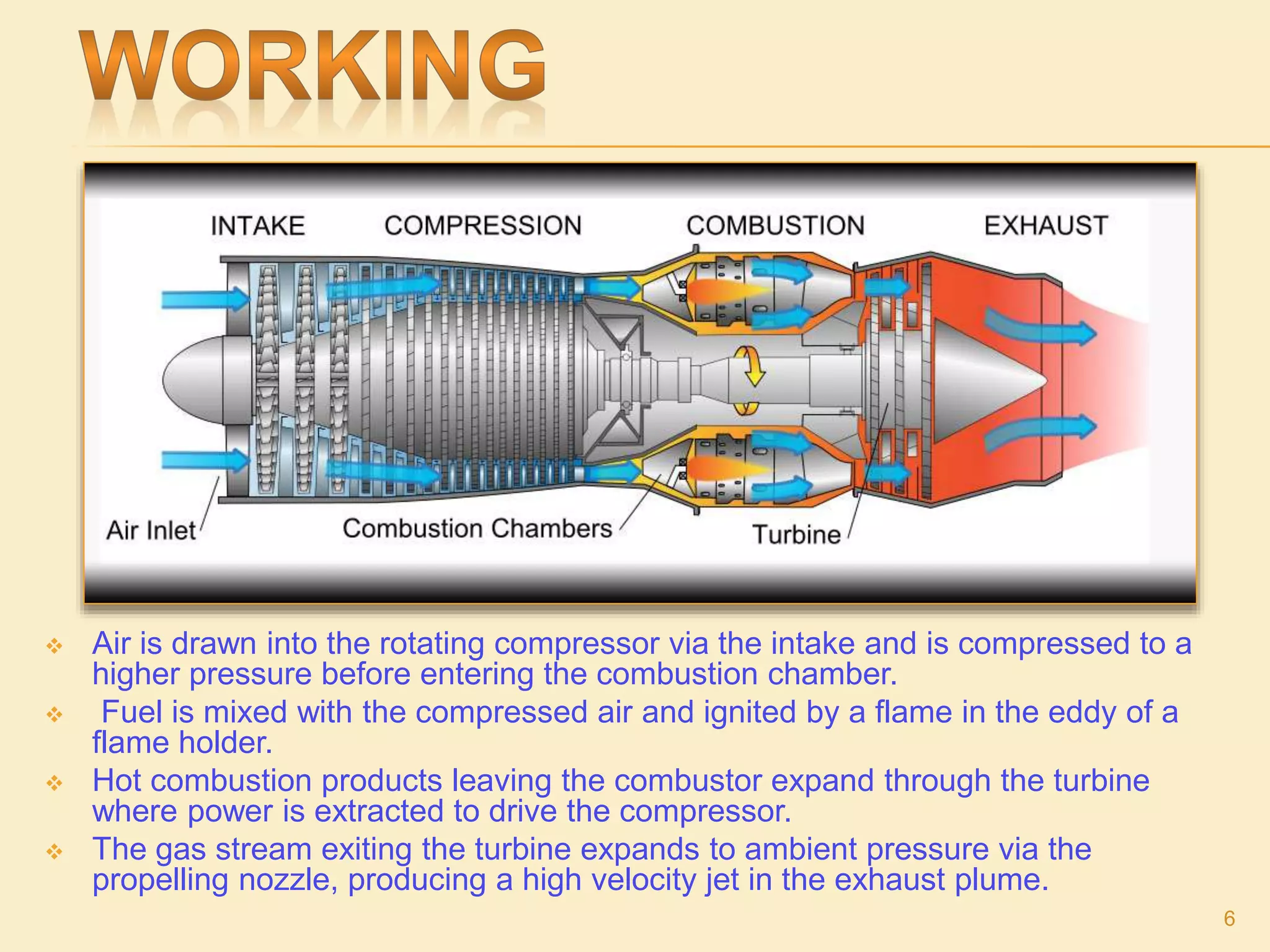

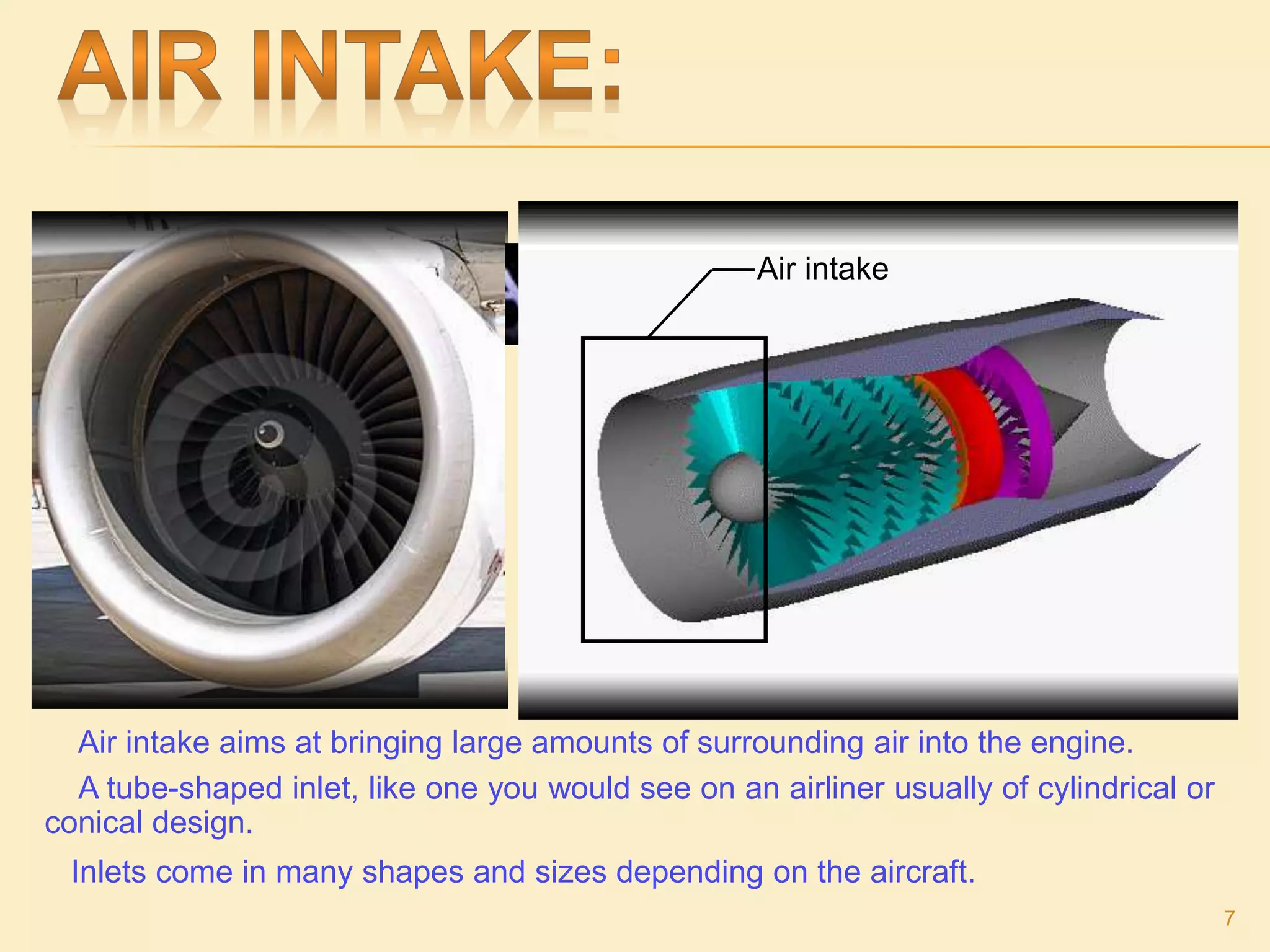

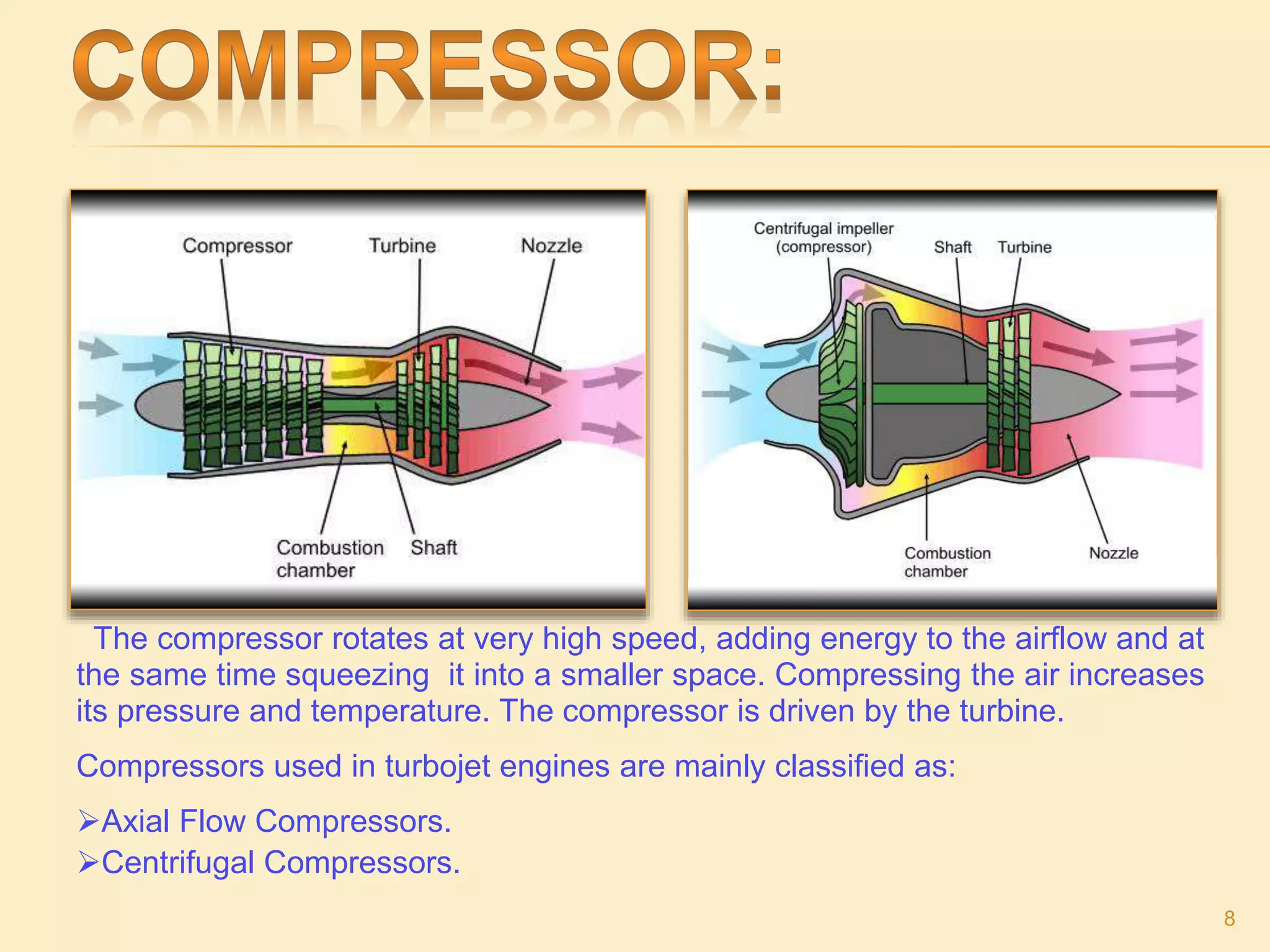

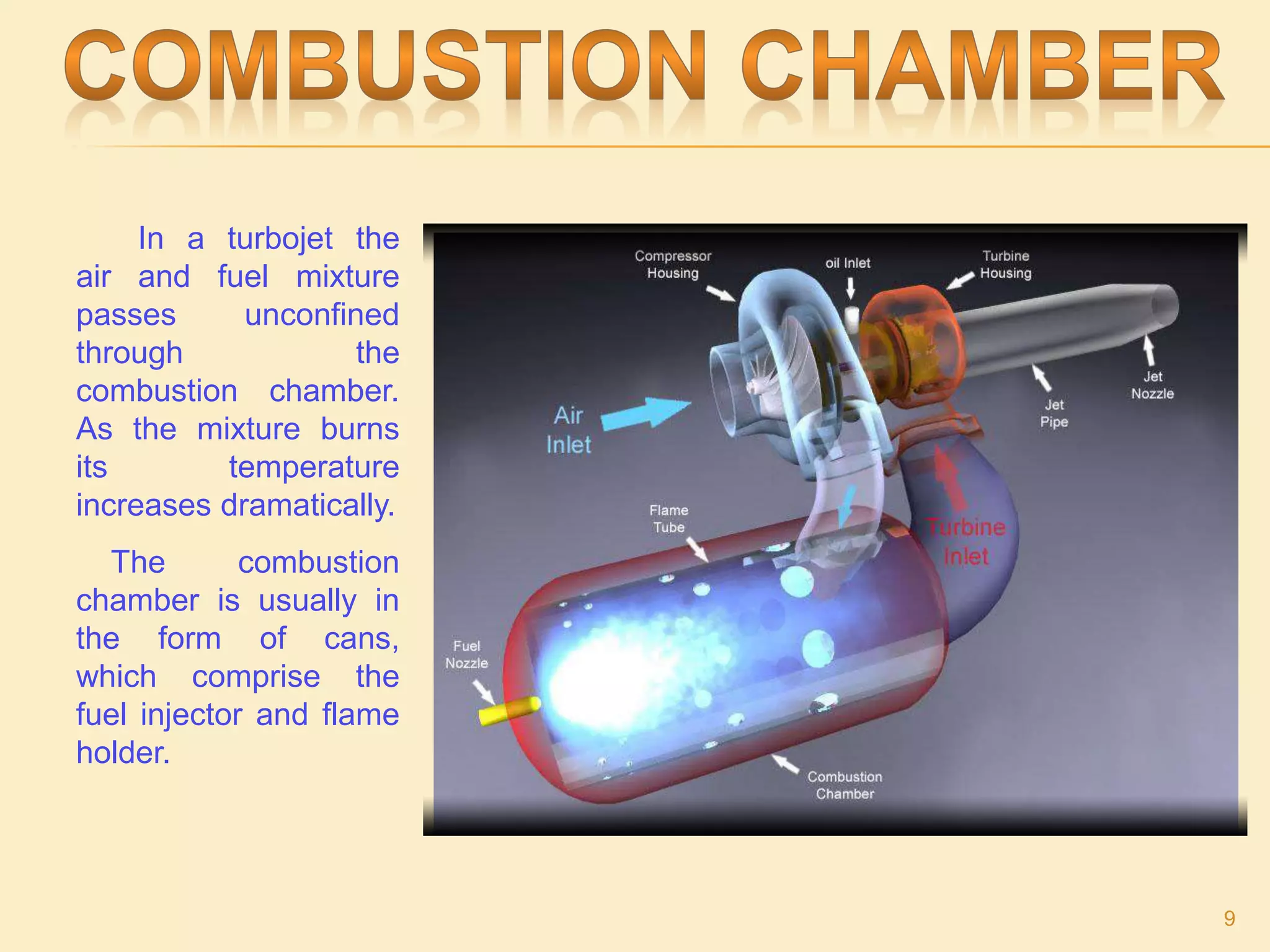

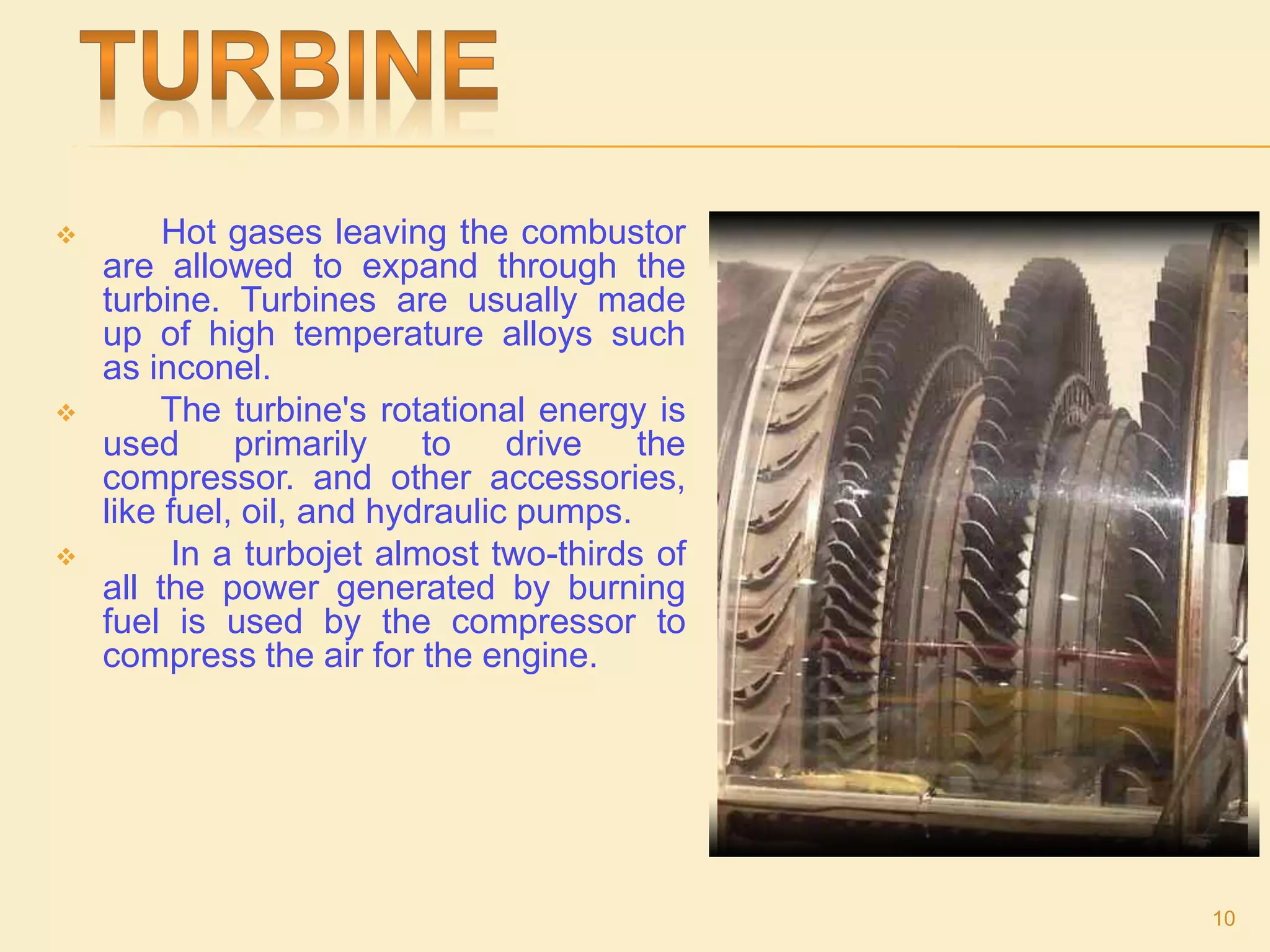

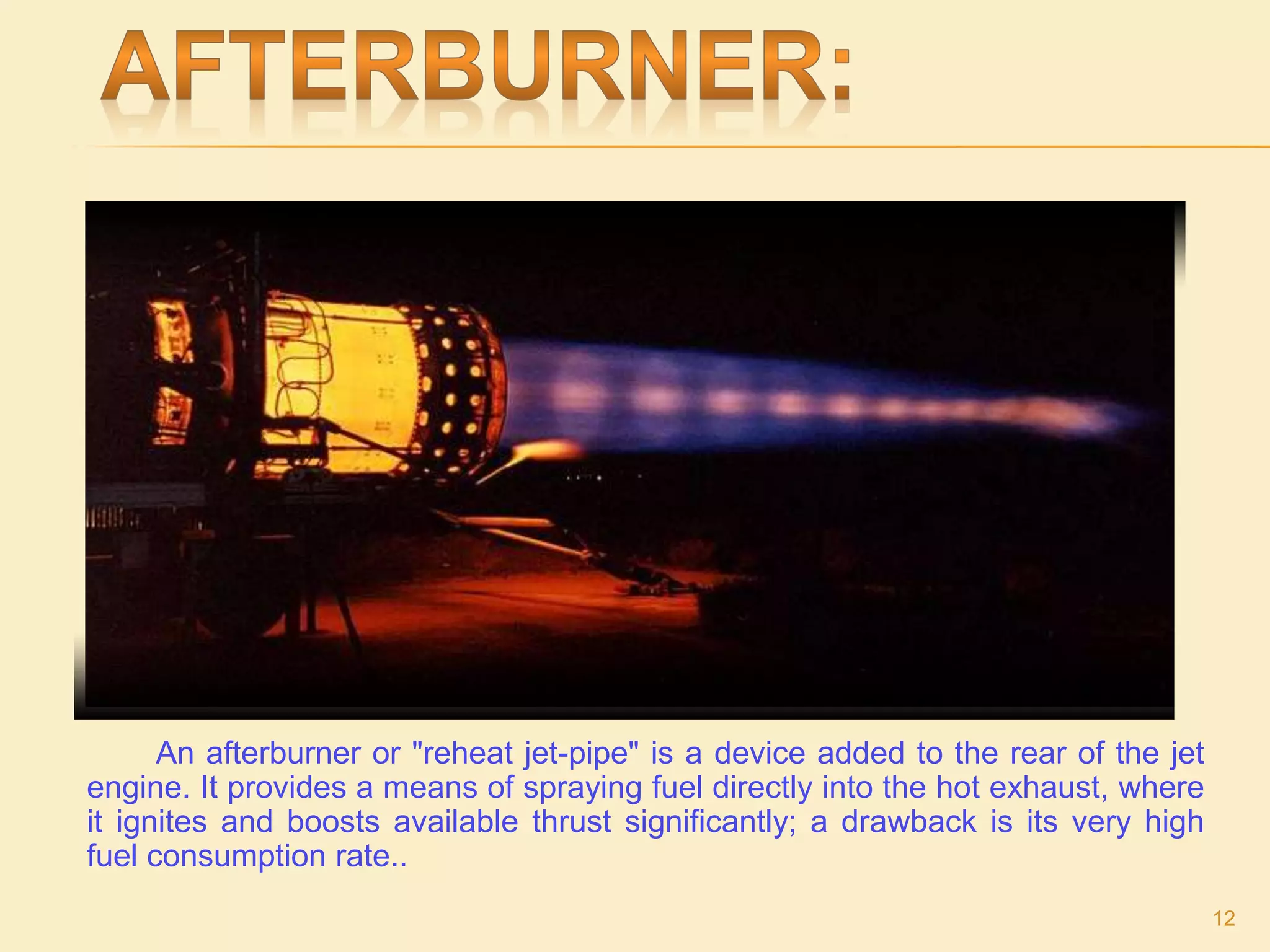

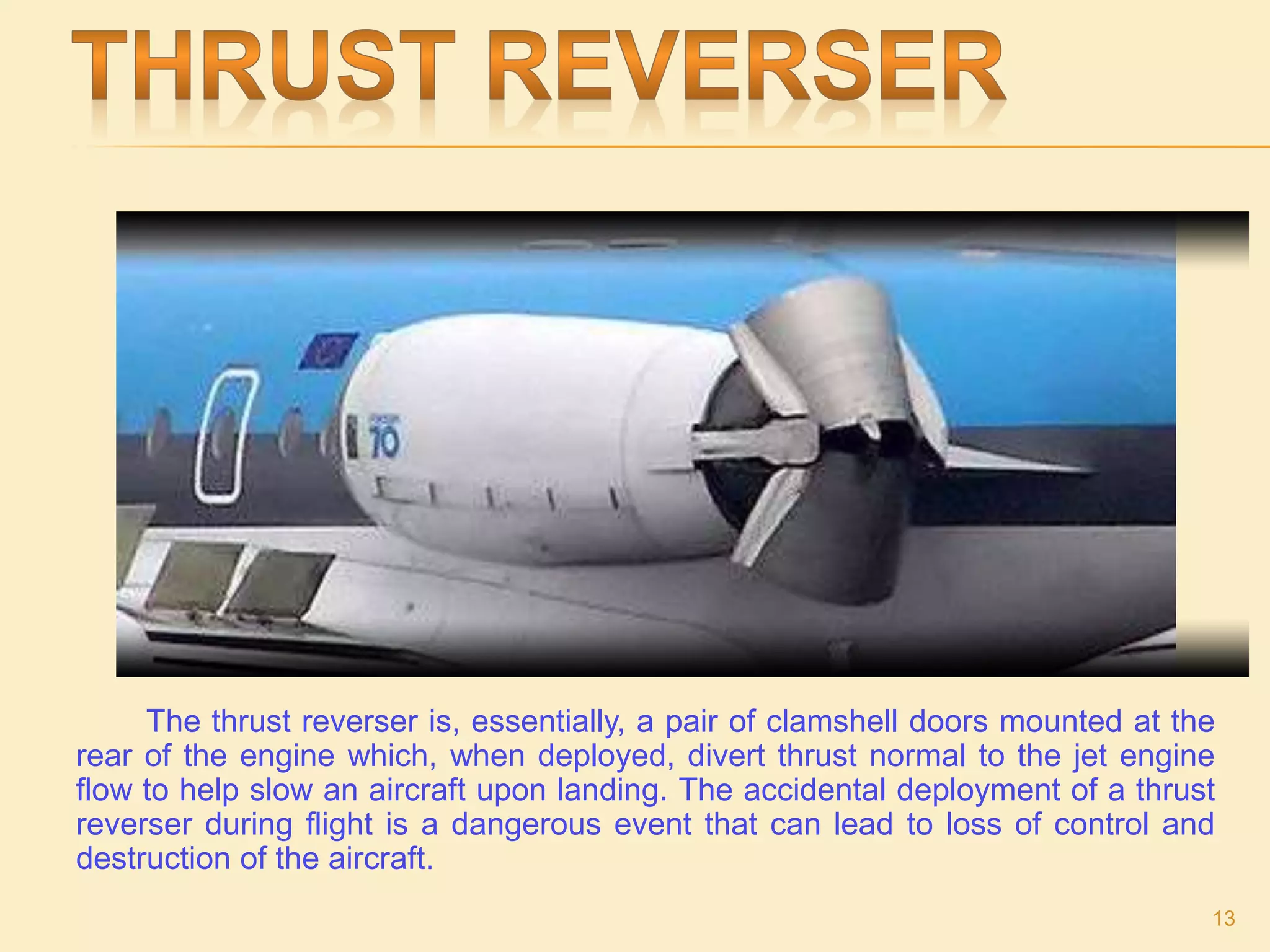

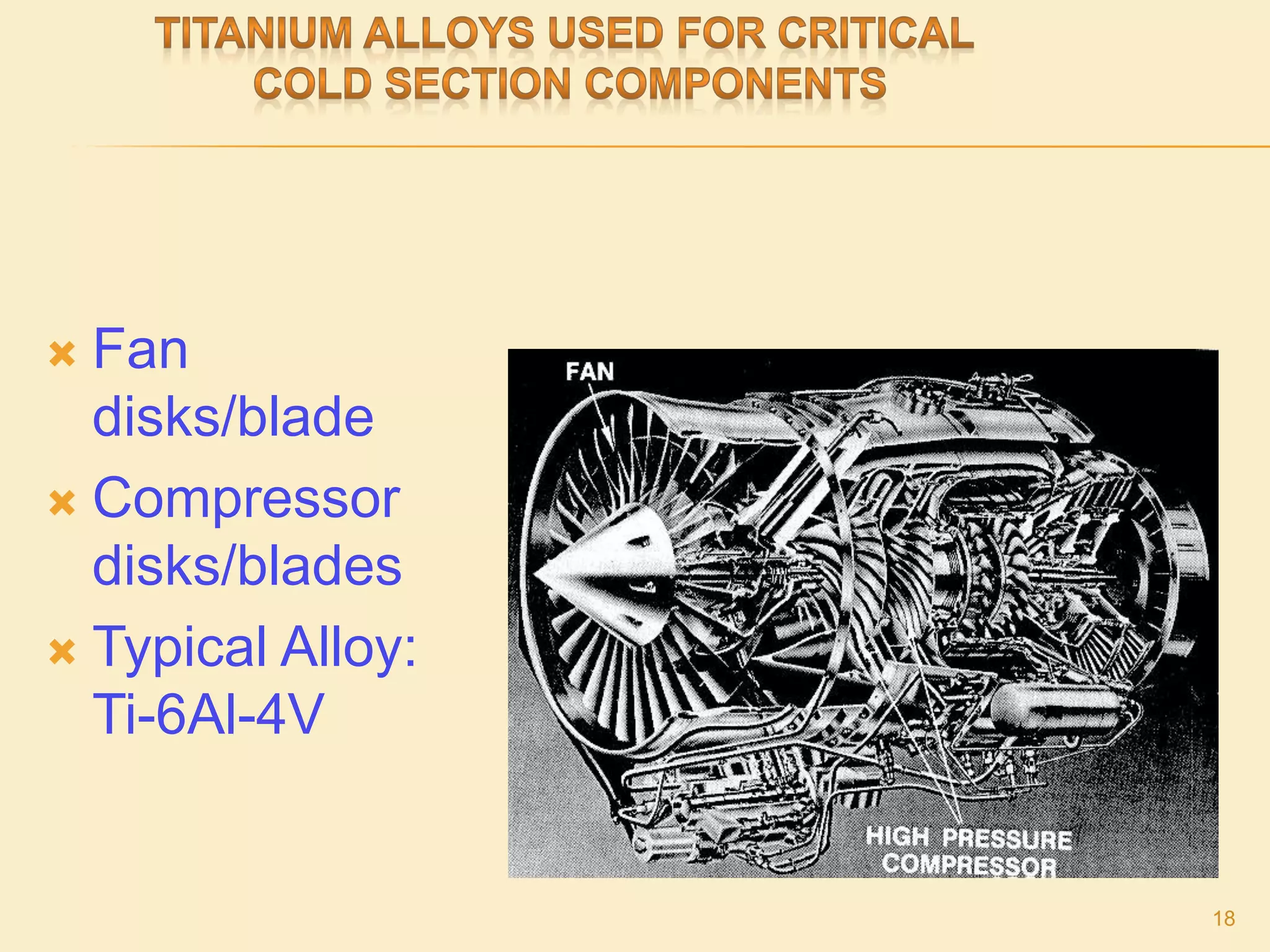

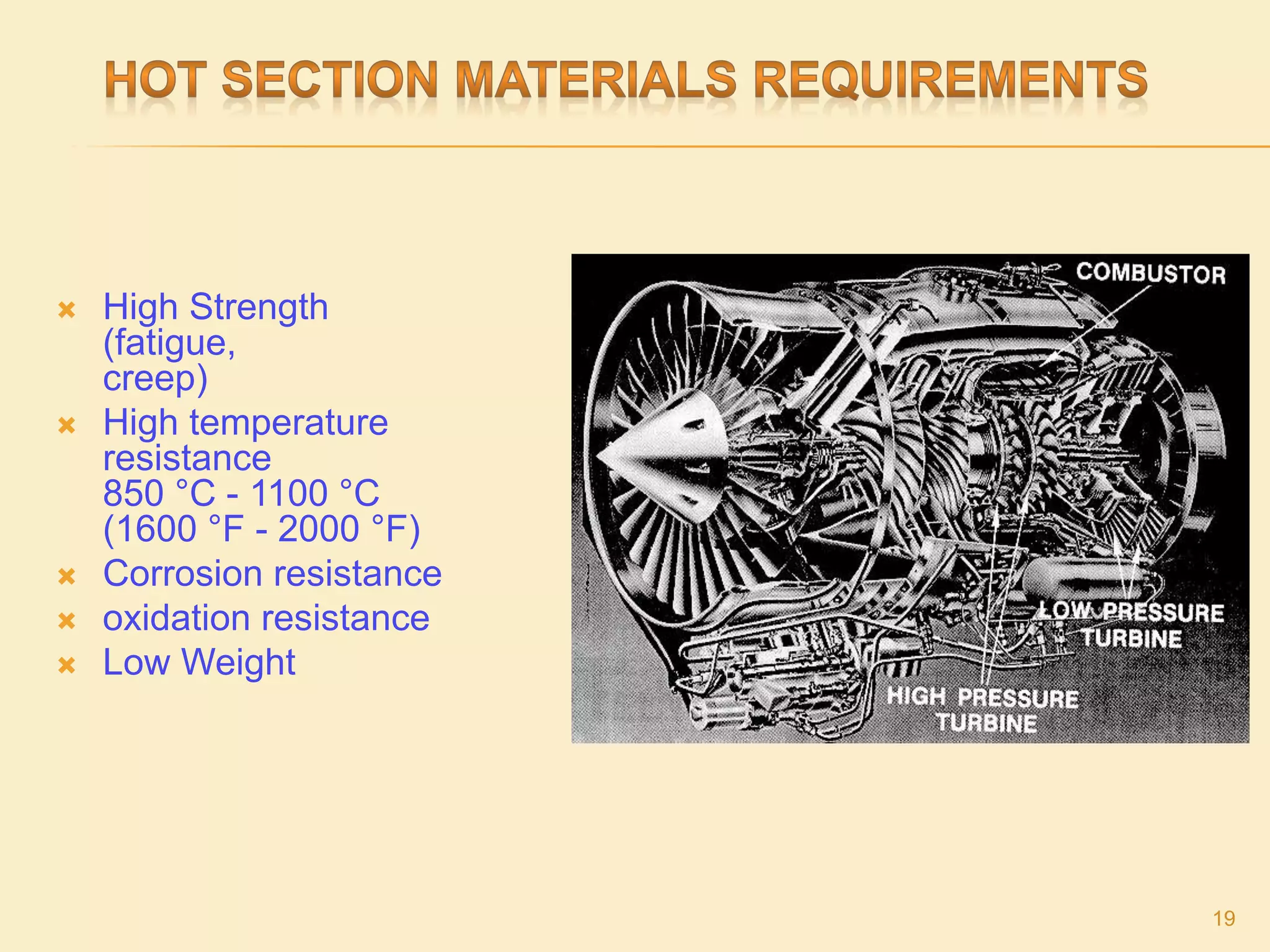

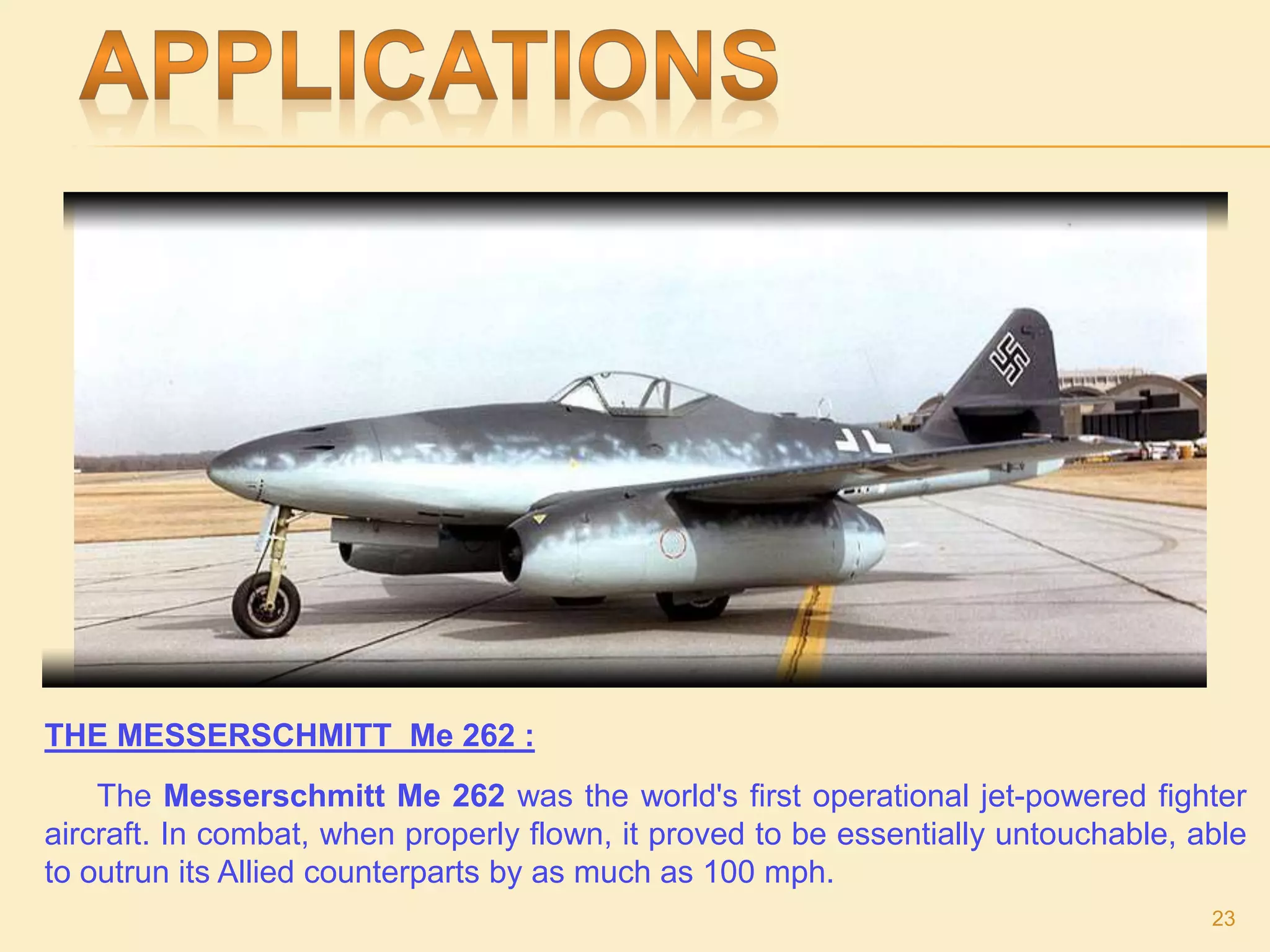

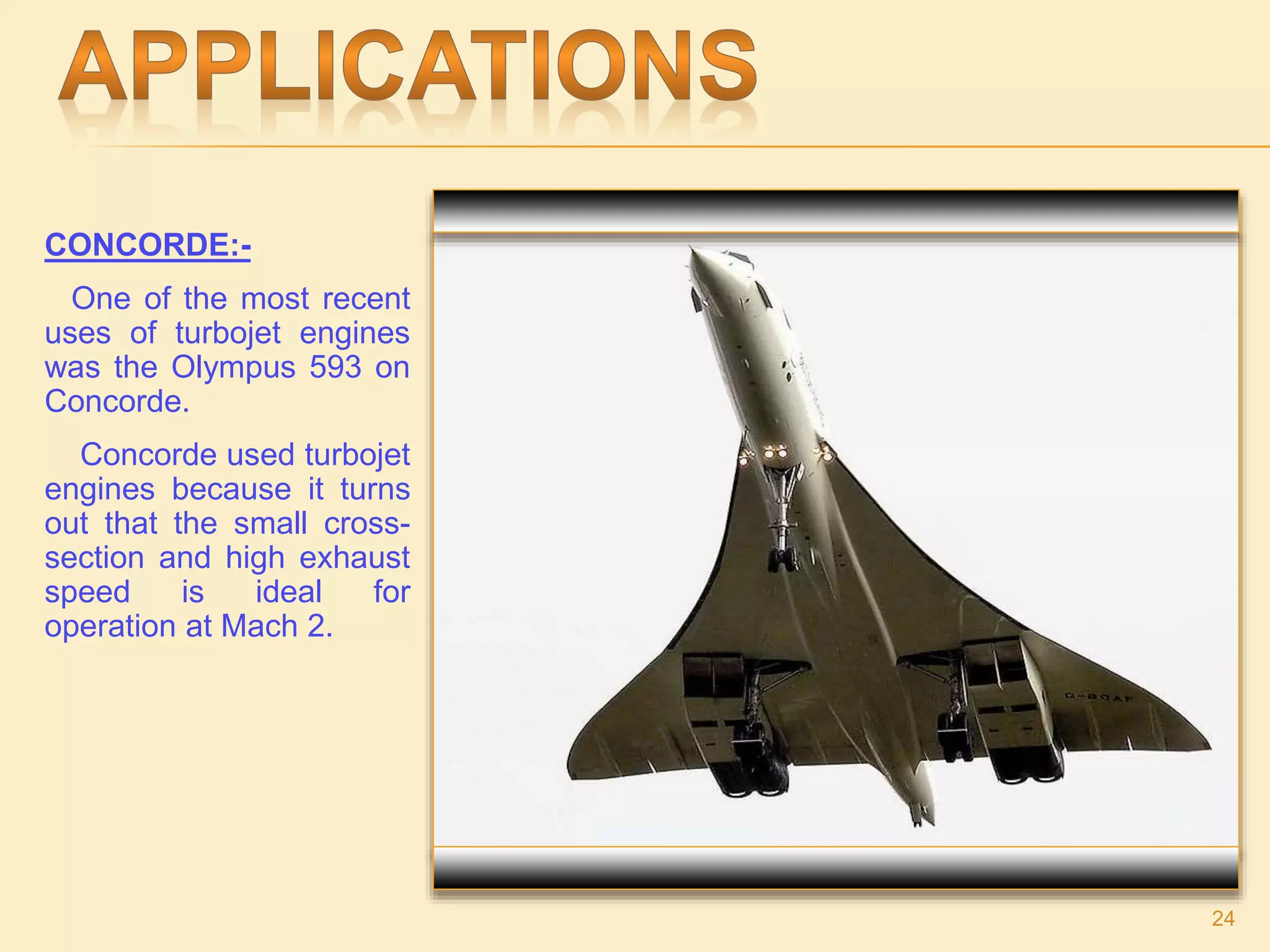

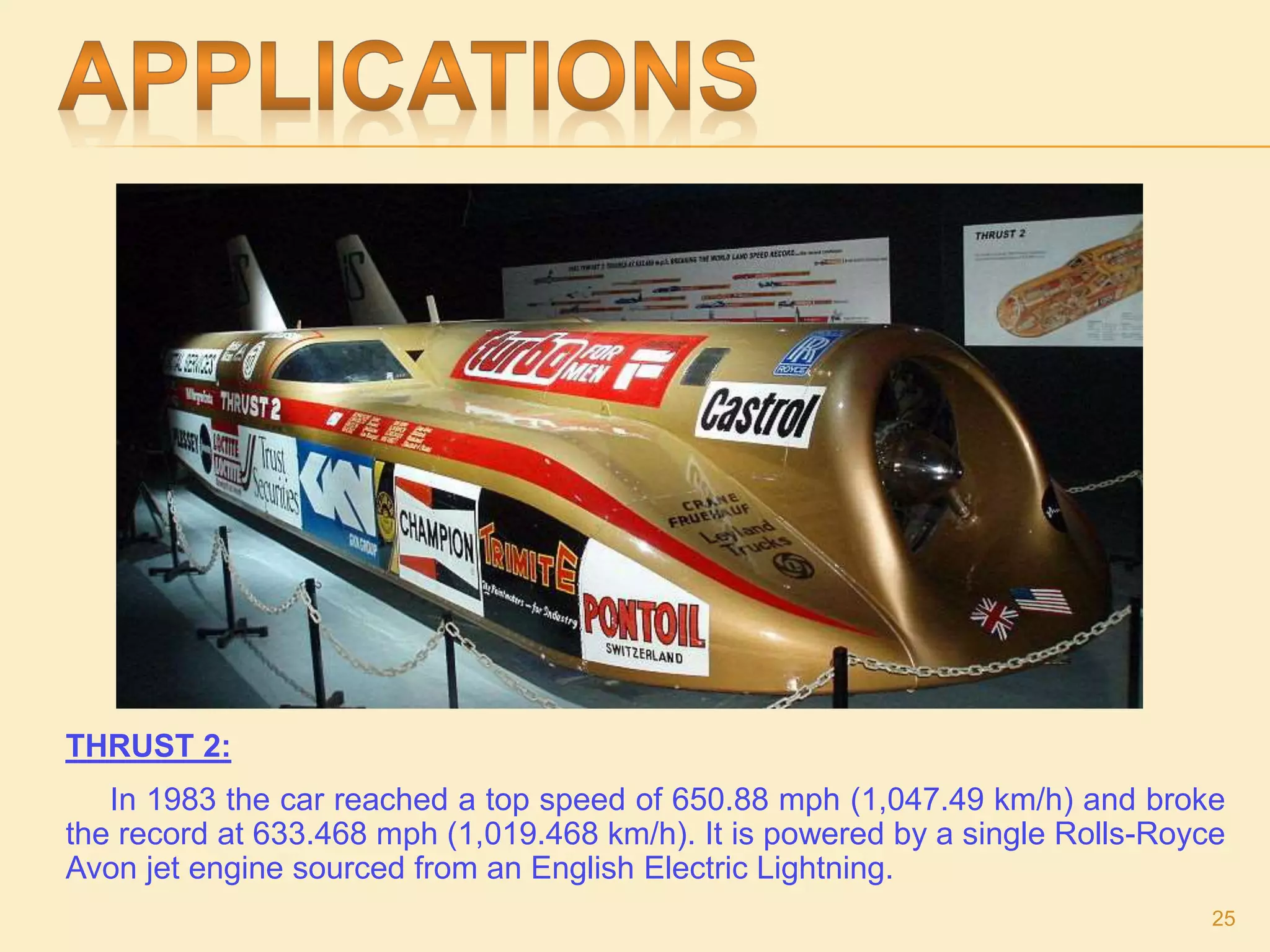

The document presents an introduction to turbojet engines, explaining their components, working principles, and applications. It covers critical aspects such as afterburners, thrust reversers, and the materials used, emphasizing the merits and demerits of turbojet engines. The conclusion highlights the complexity of turbojets and the need for material development to enhance performance and reduce life cycle costs.