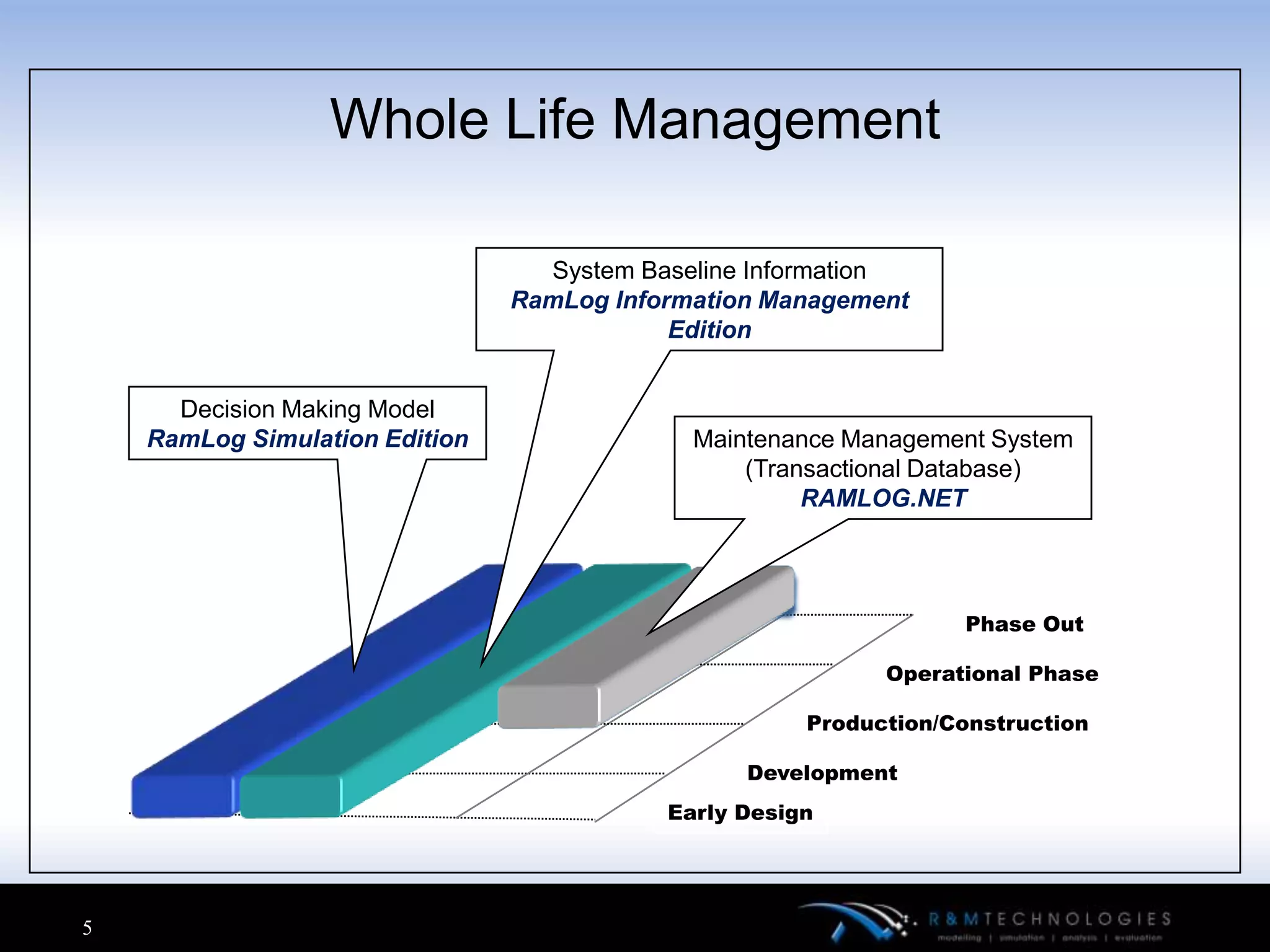

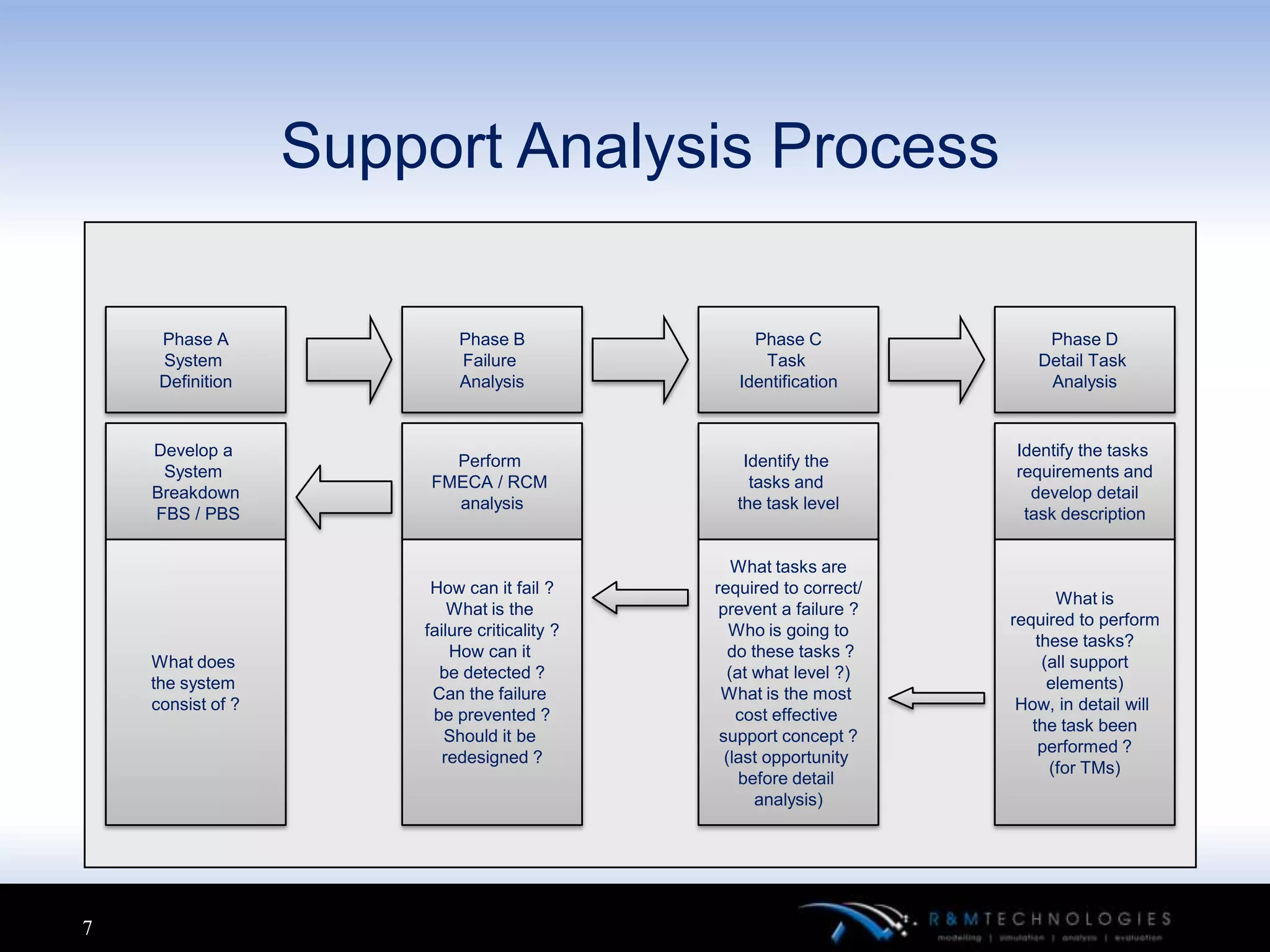

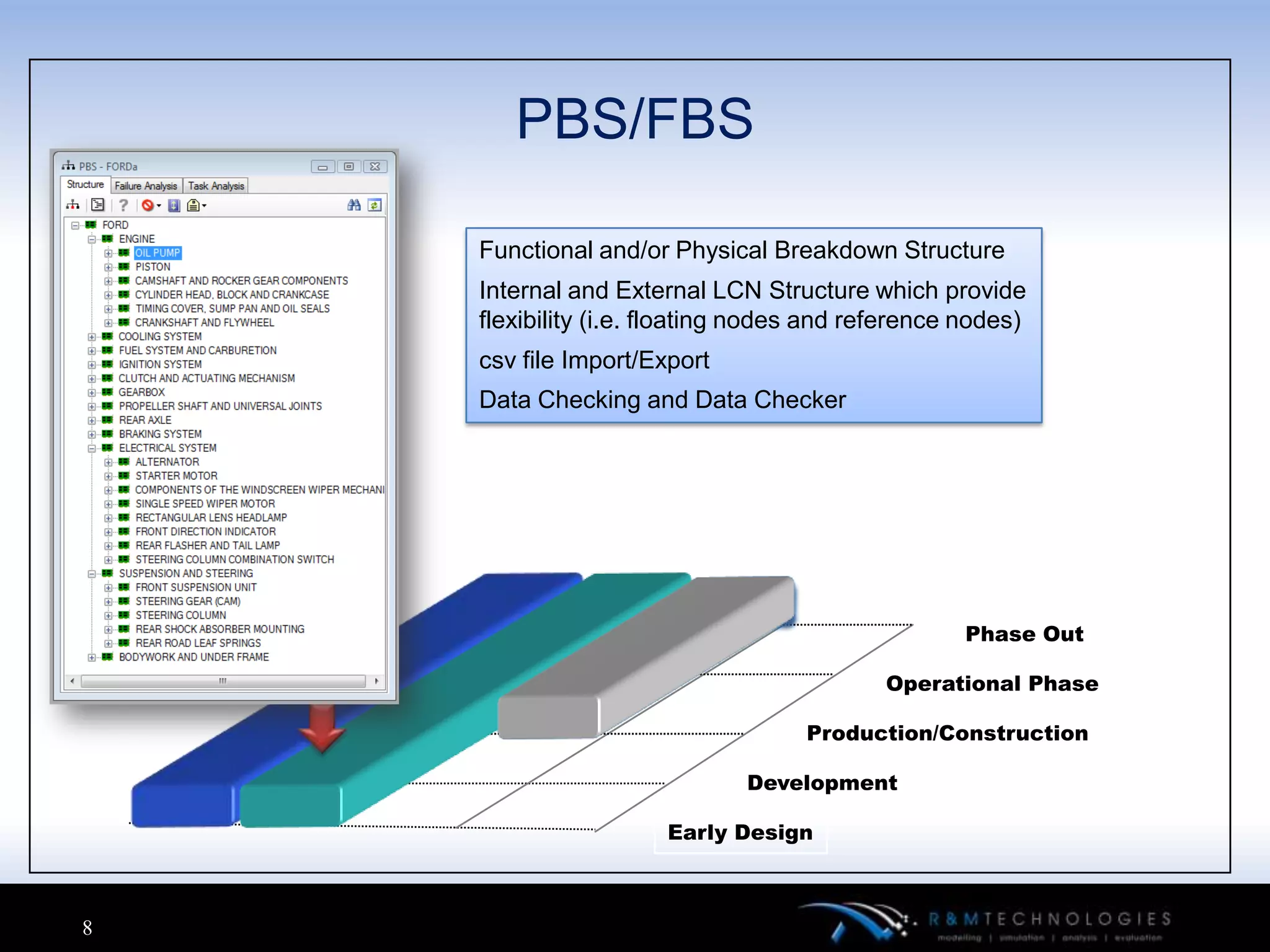

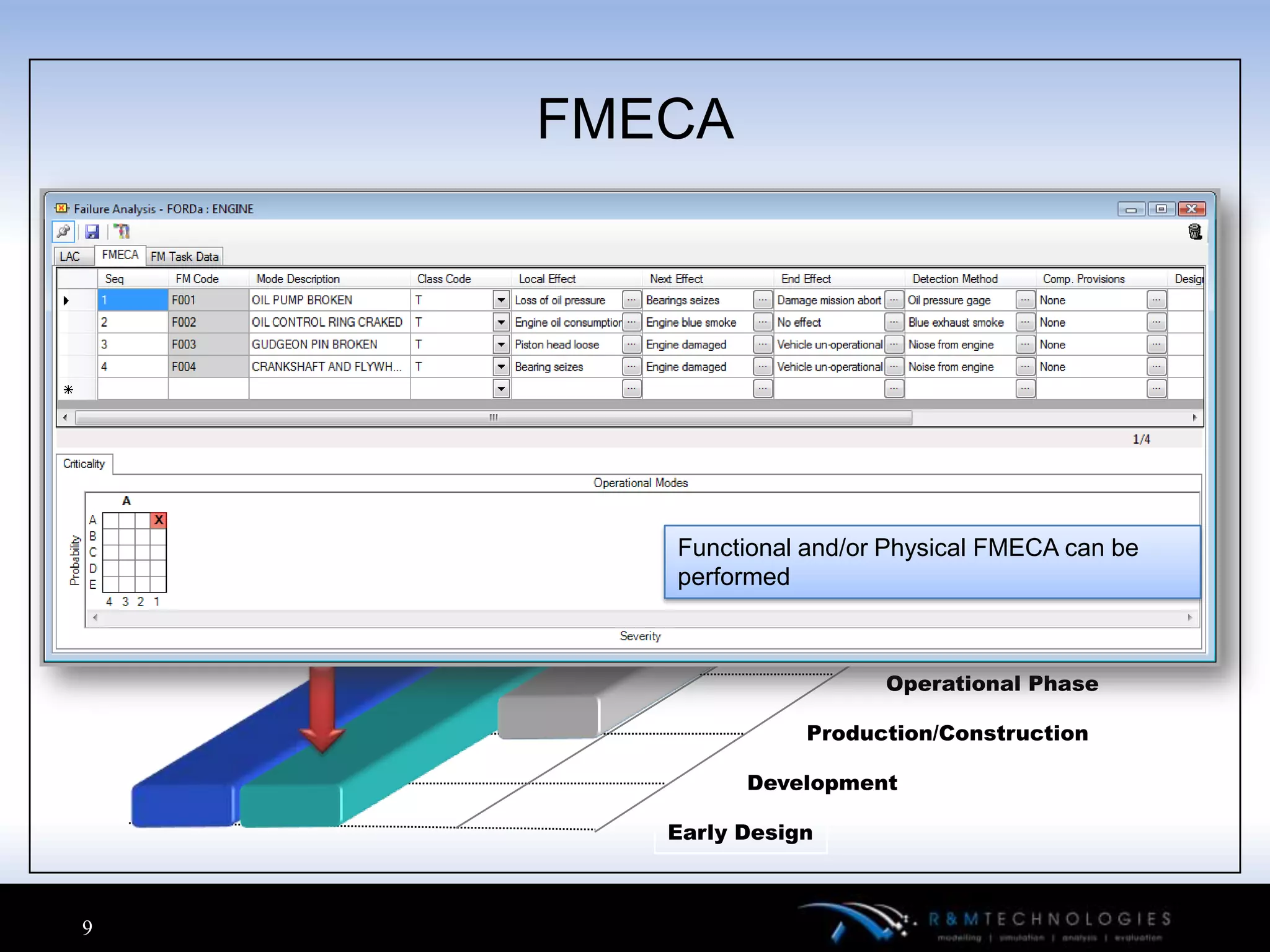

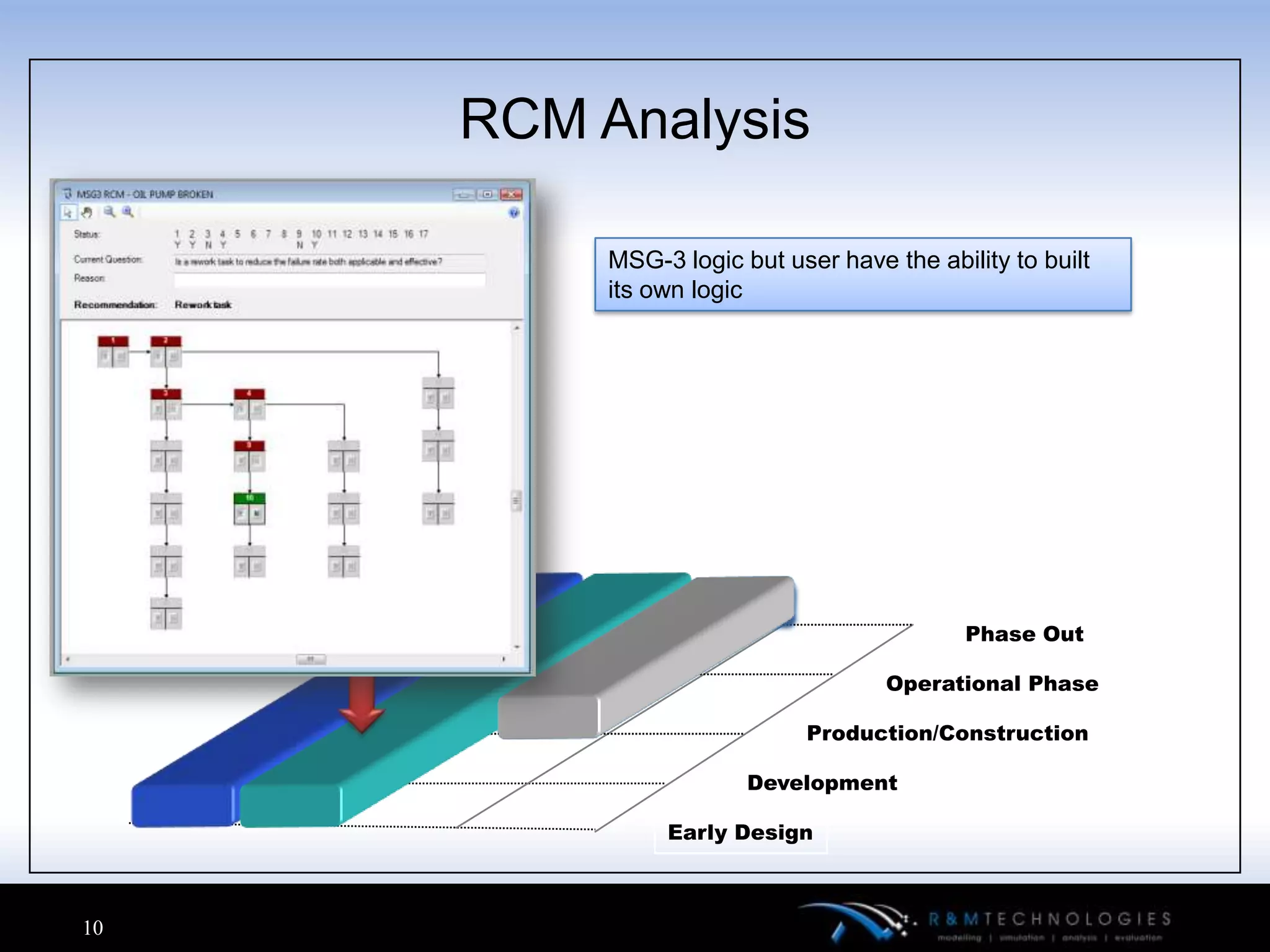

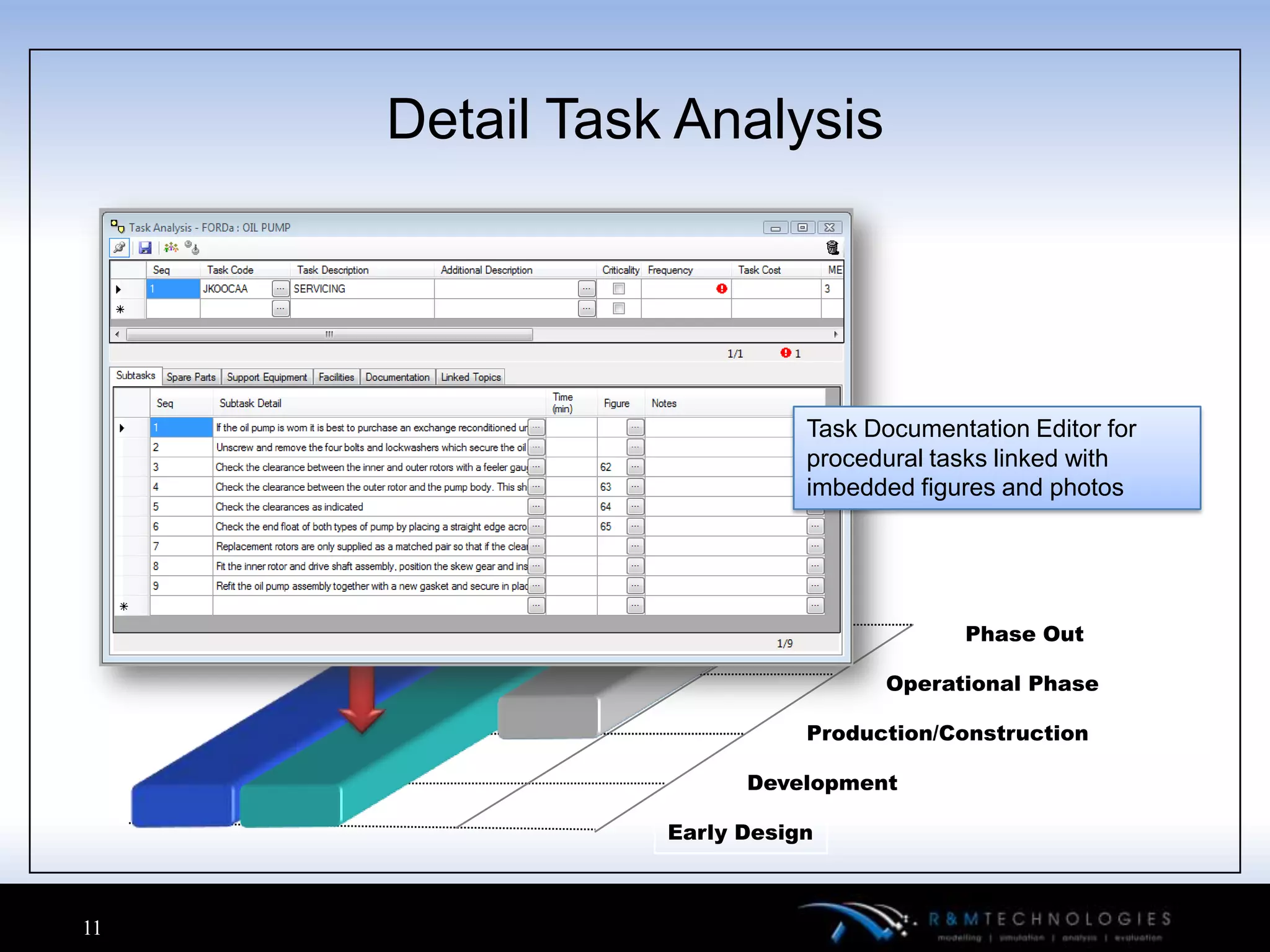

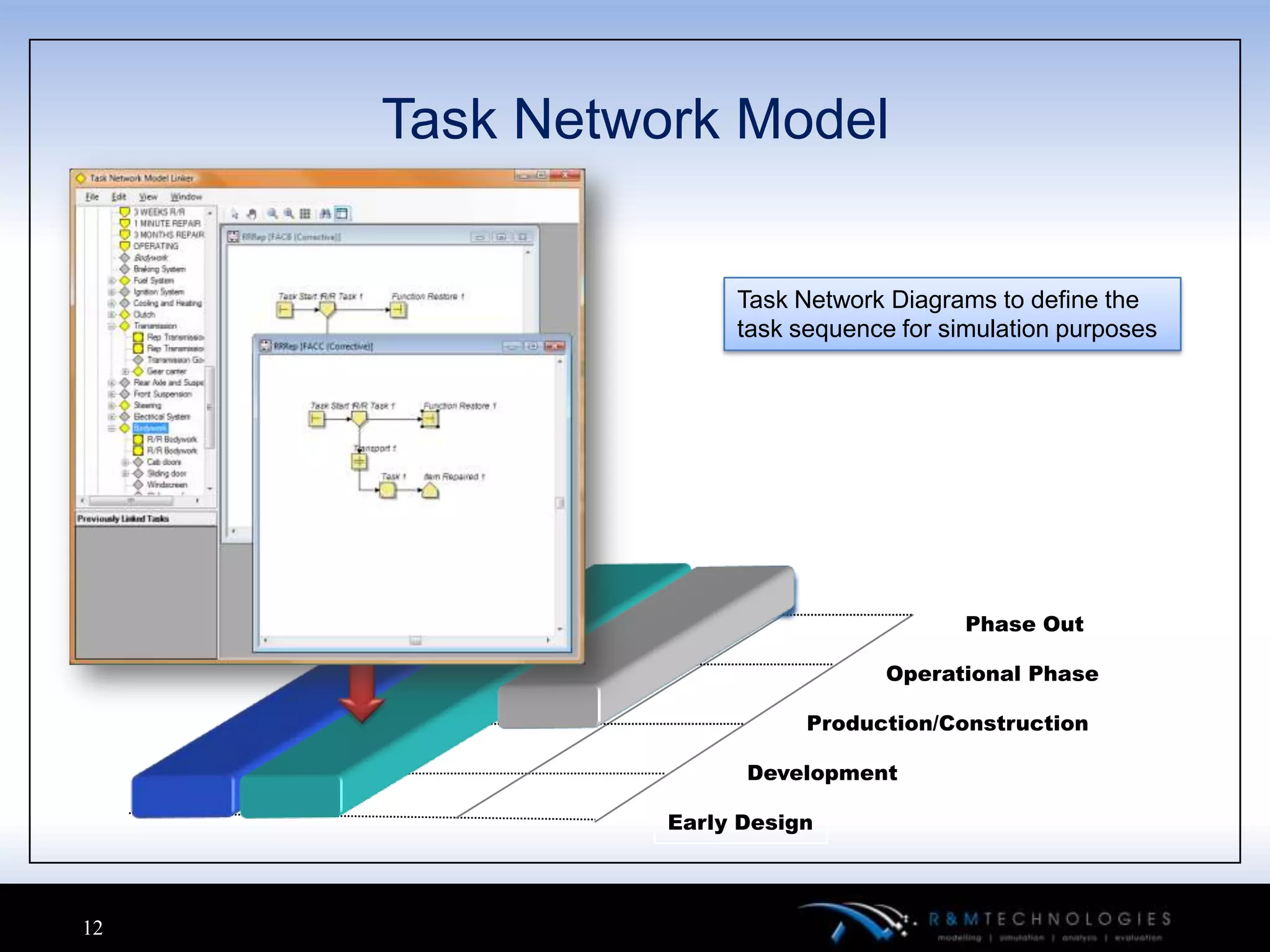

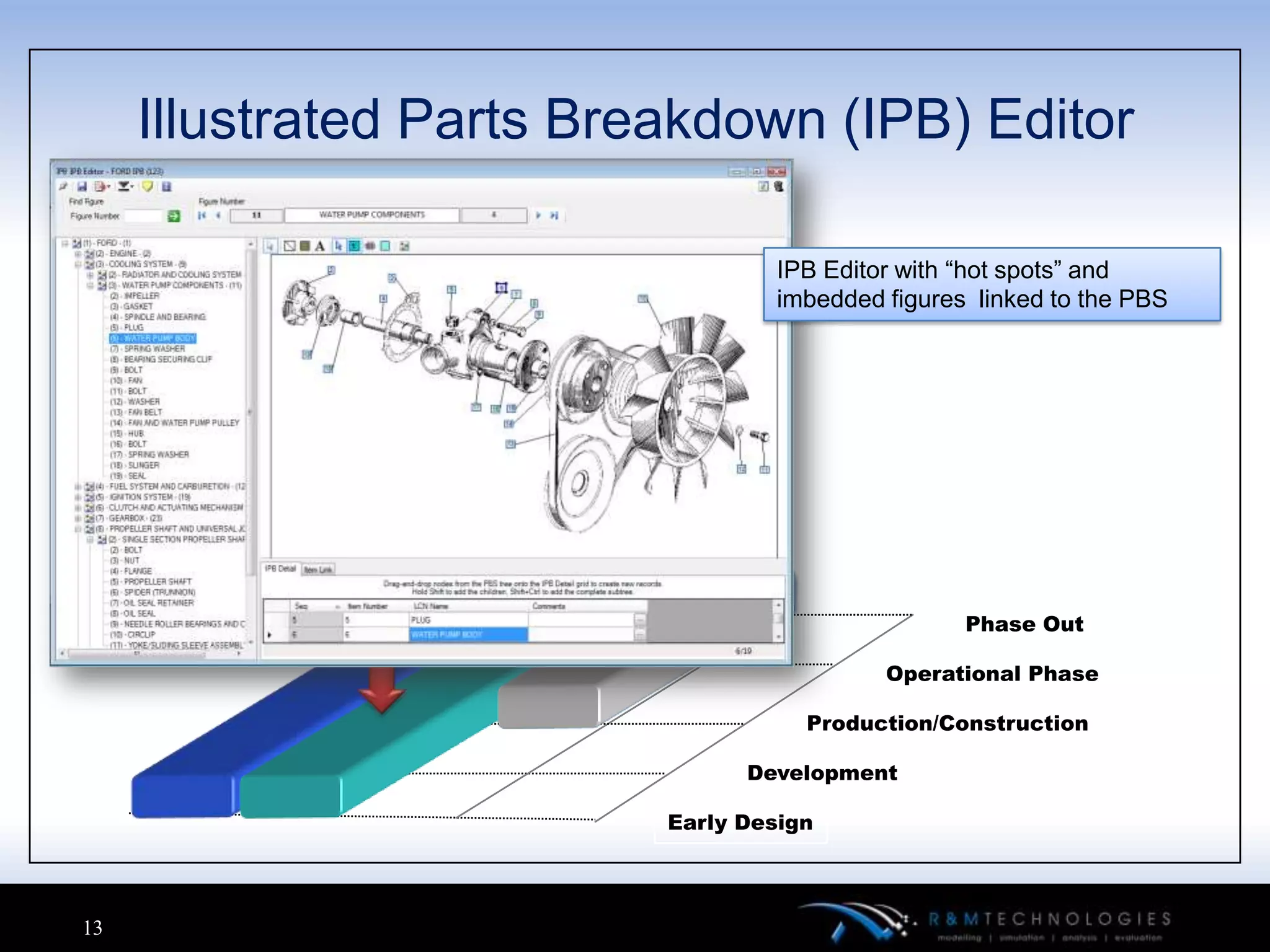

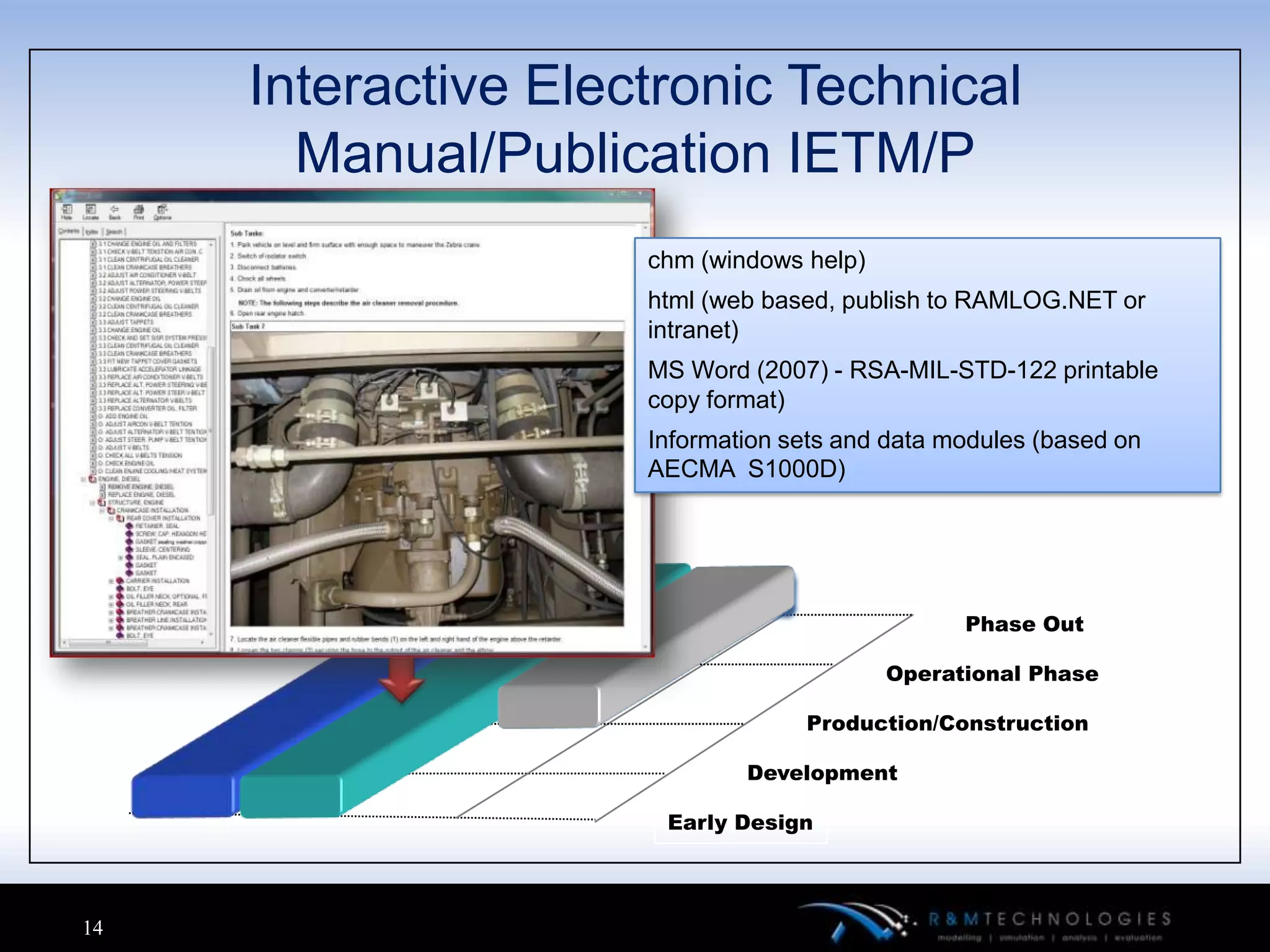

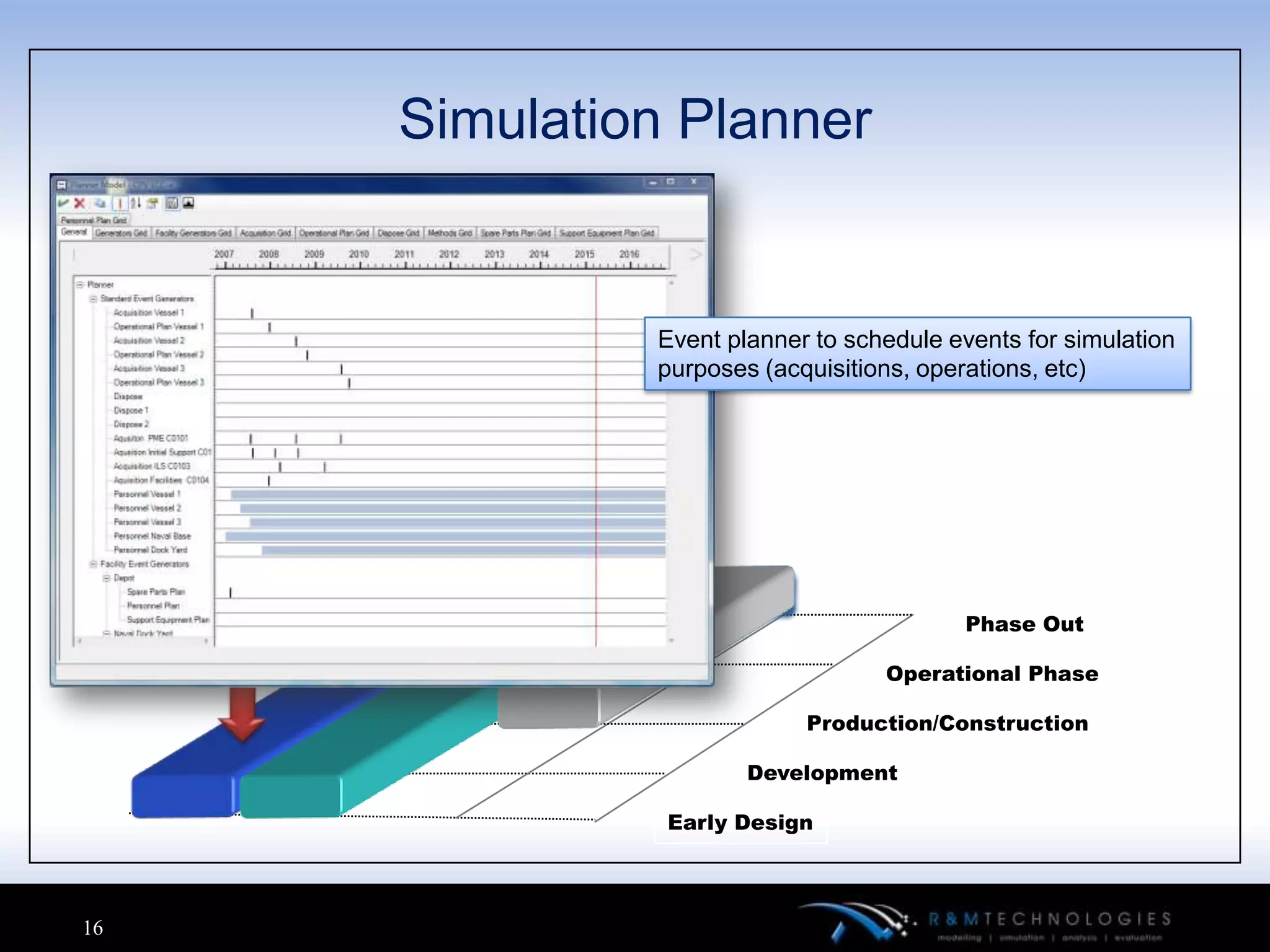

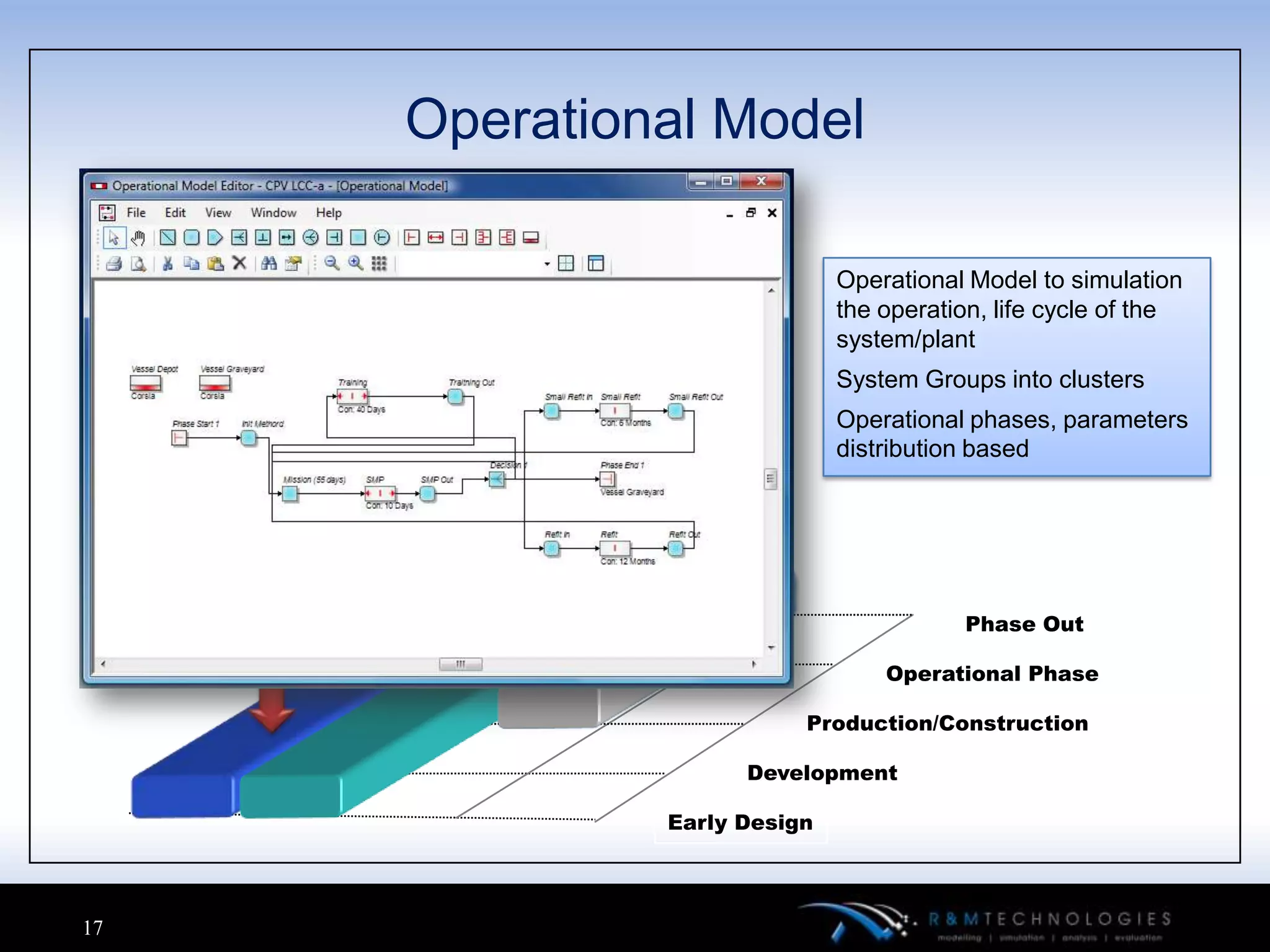

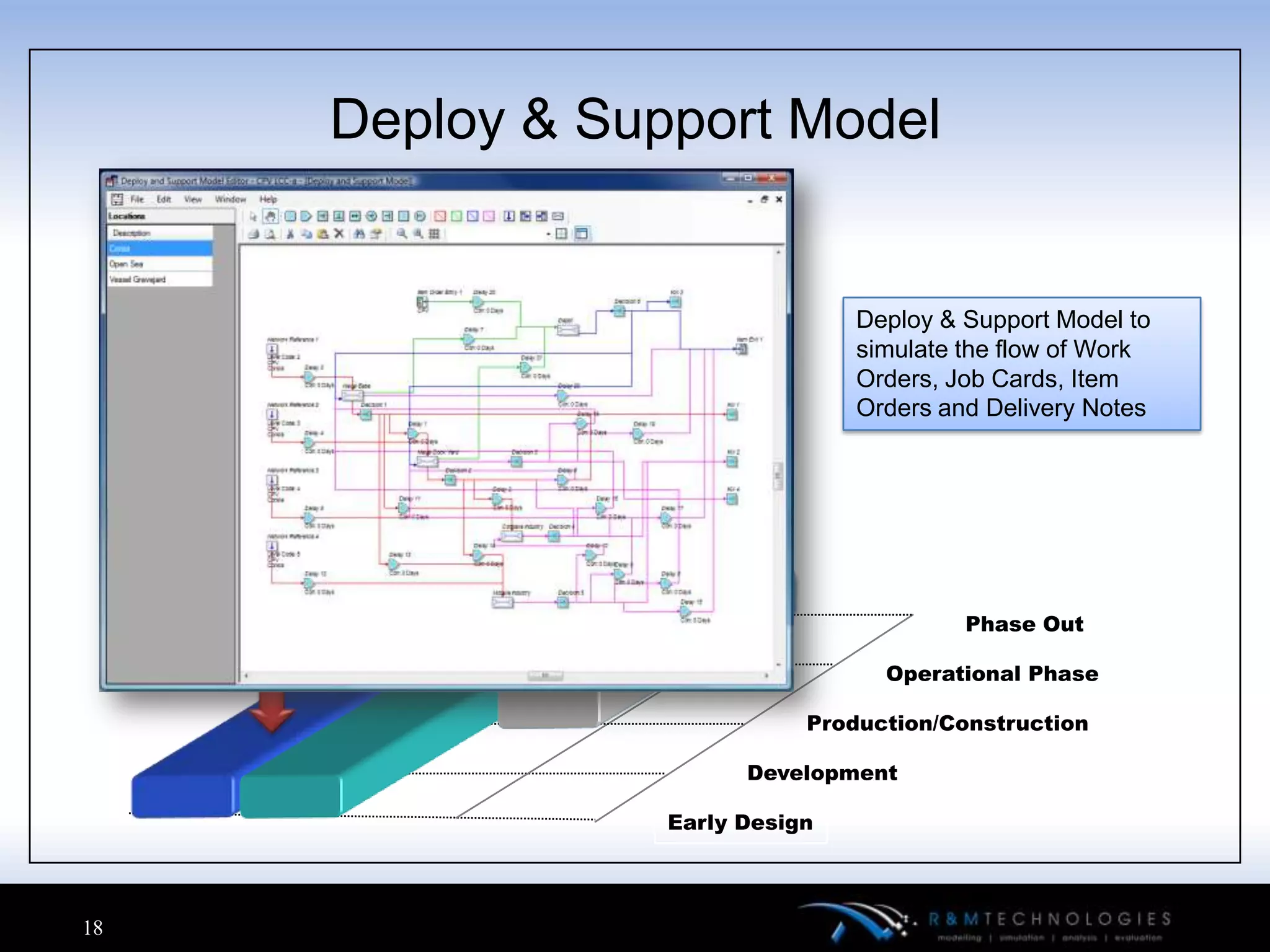

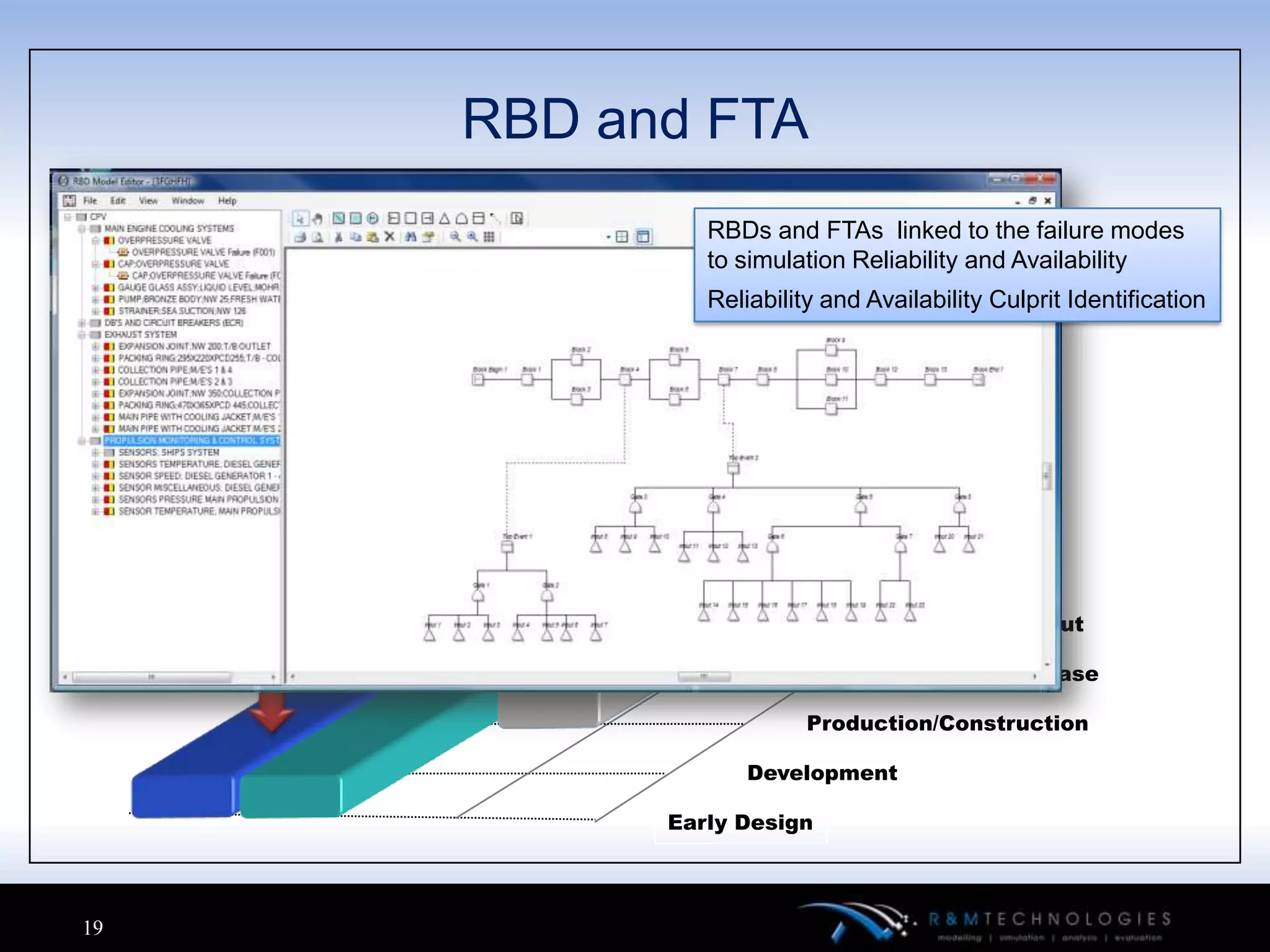

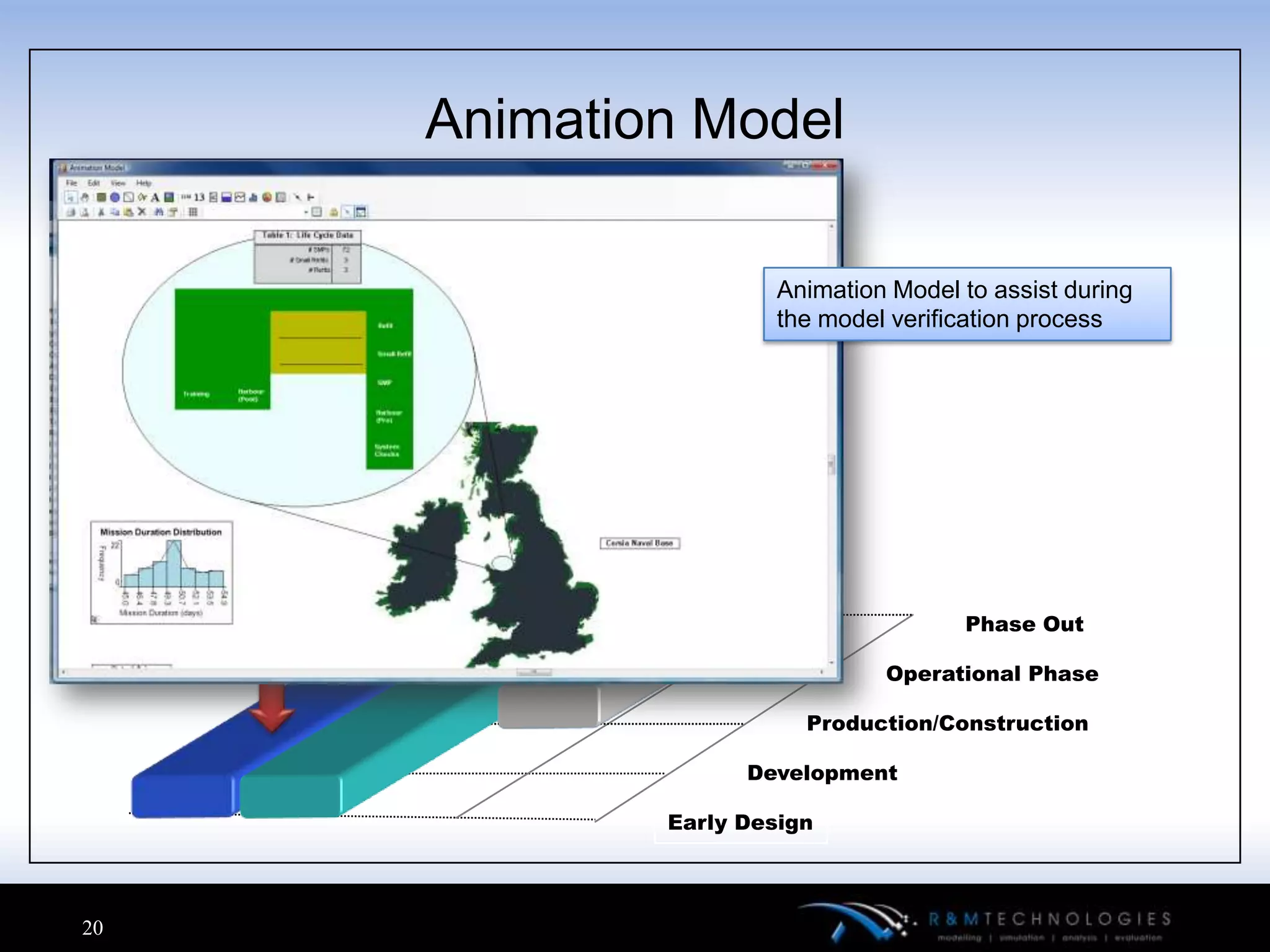

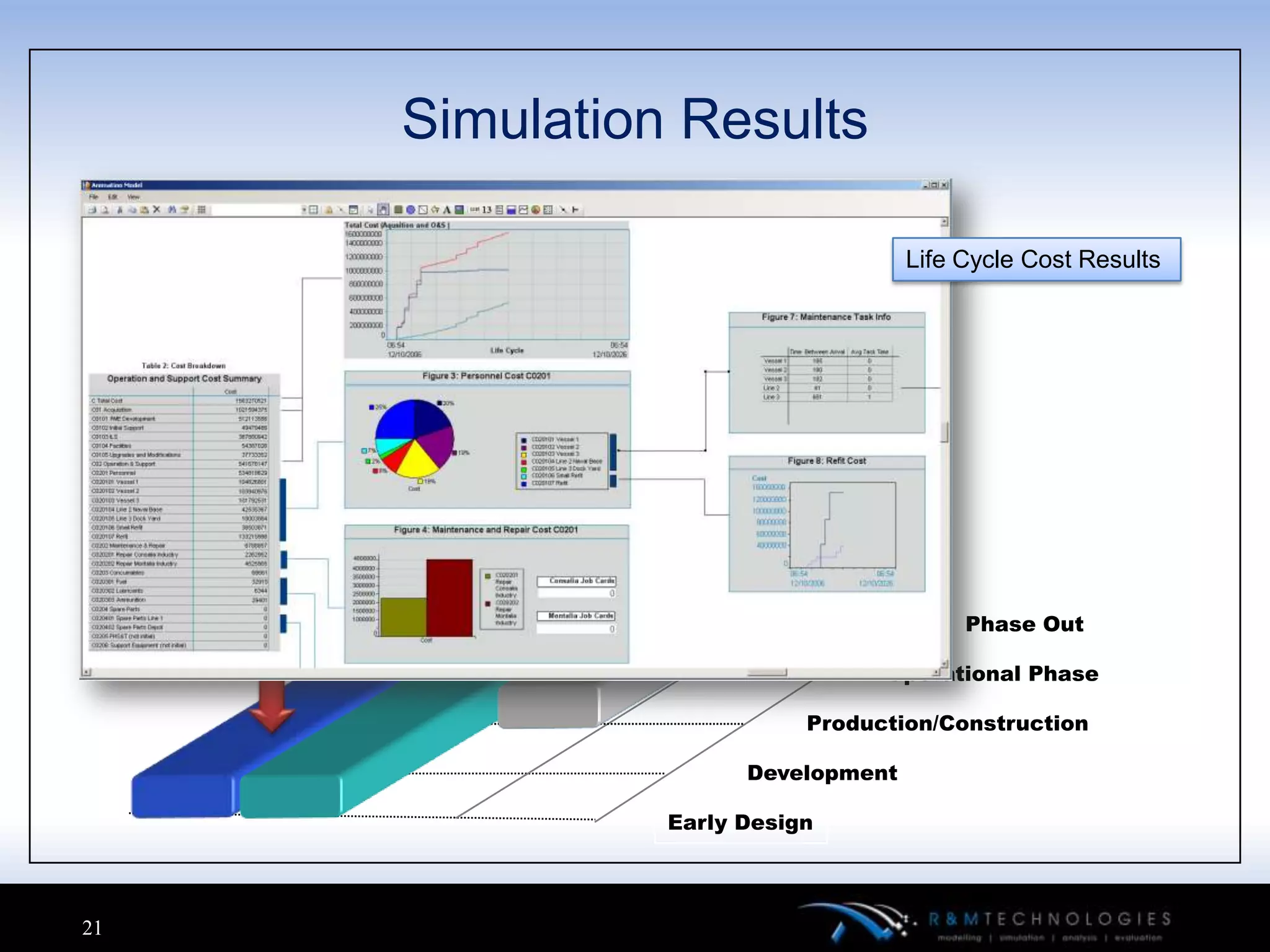

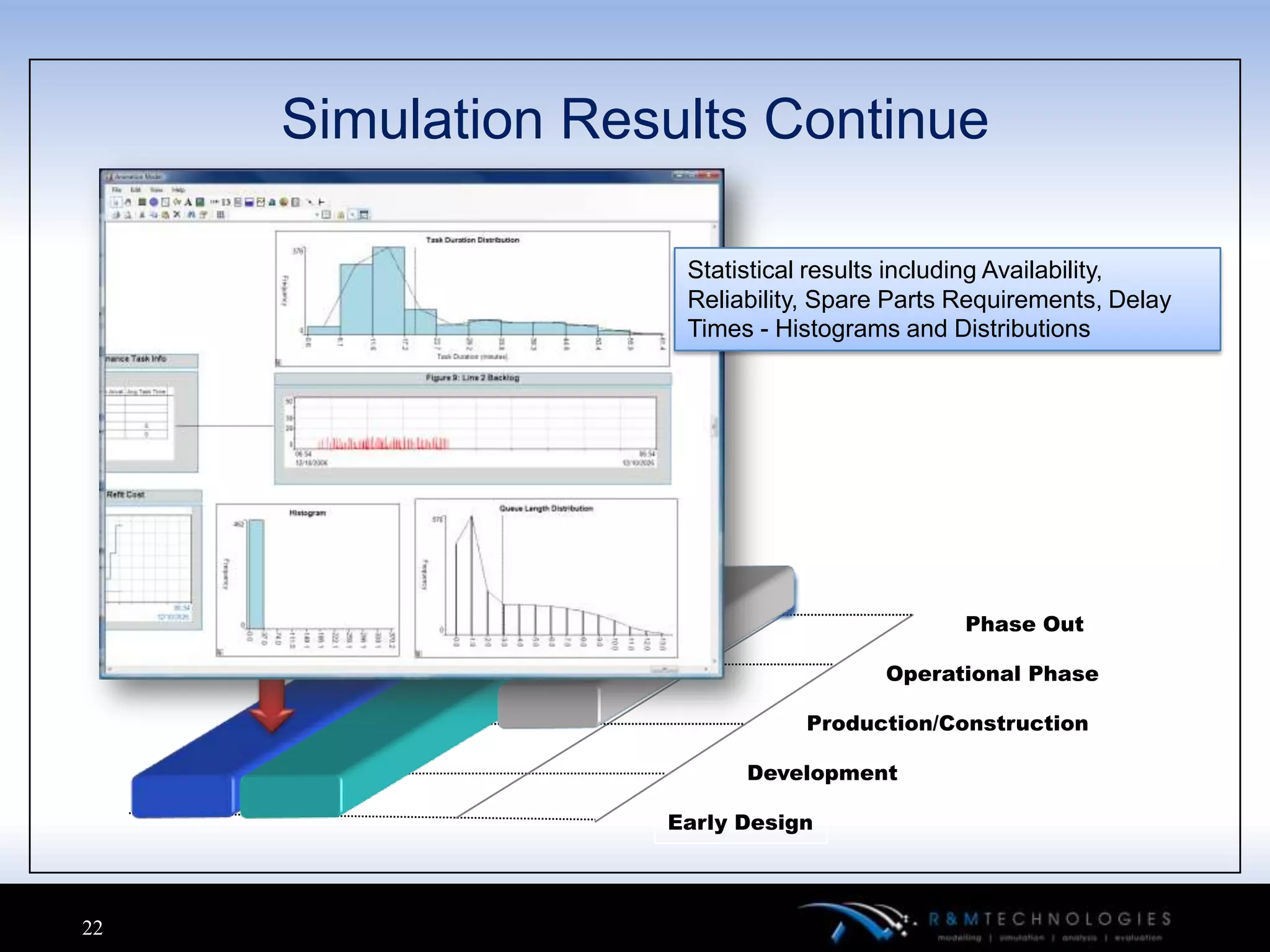

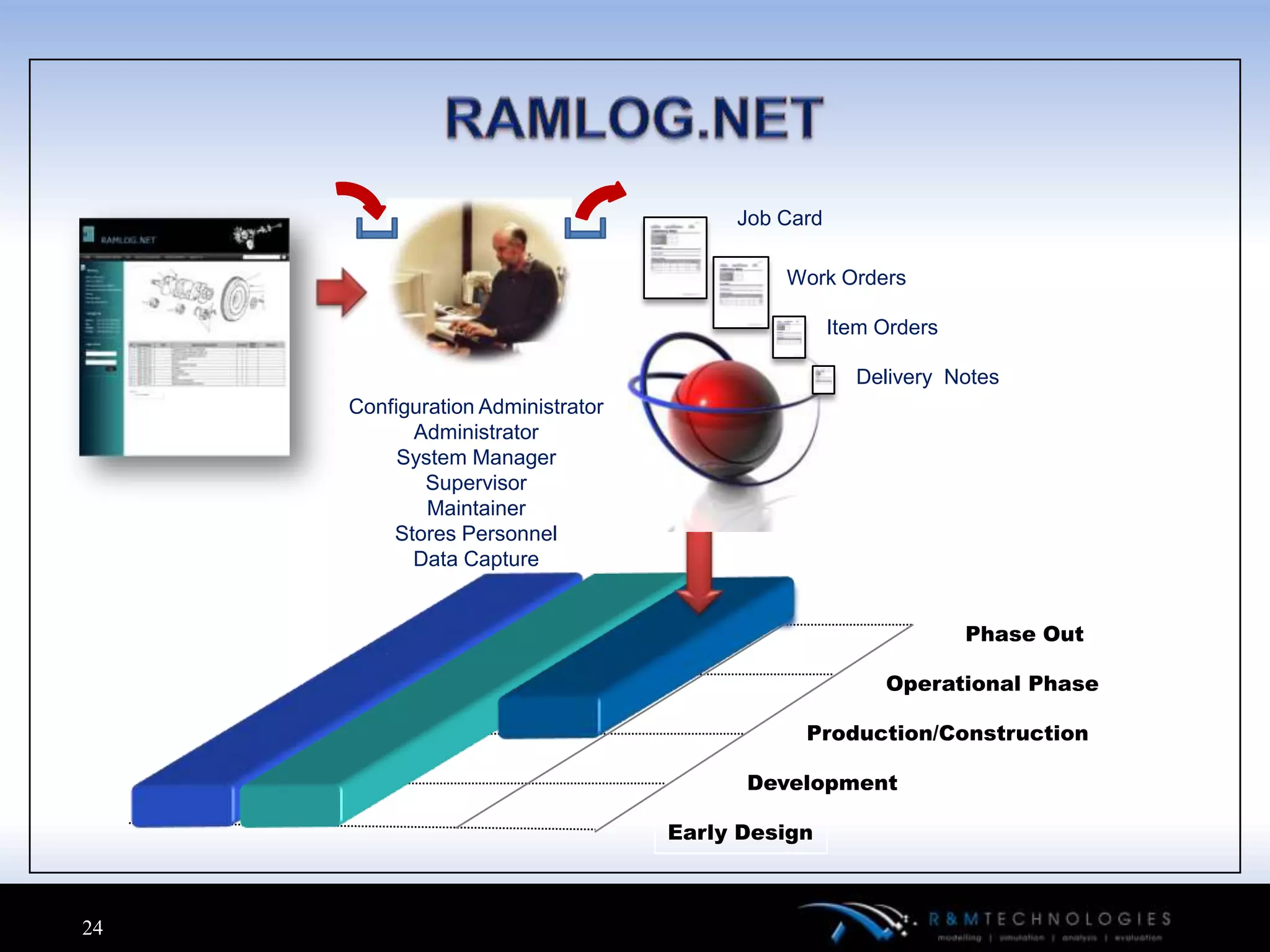

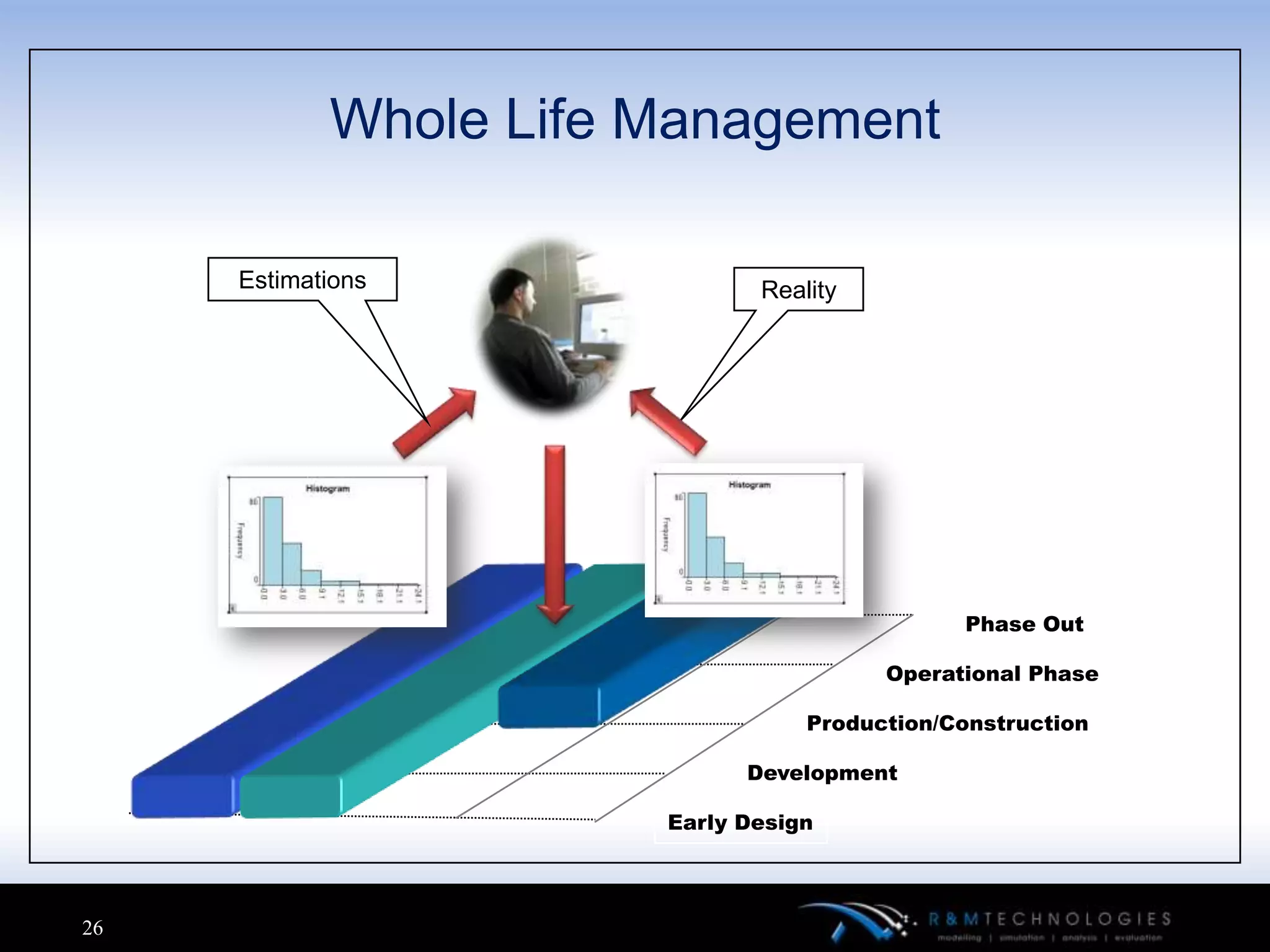

R&M Technologies provides reliability, maintainability and logistics support analysis services. It developed RamLog software in 1992 to manage lifecycle logistics data. RamLog includes capabilities like FMECA, RCM analysis, maintenance task analysis, technical manual authoring, and a simulation edition to model system operations and support over the lifecycle. RamLog integrates with RAMLOG.NET for transactional database support.