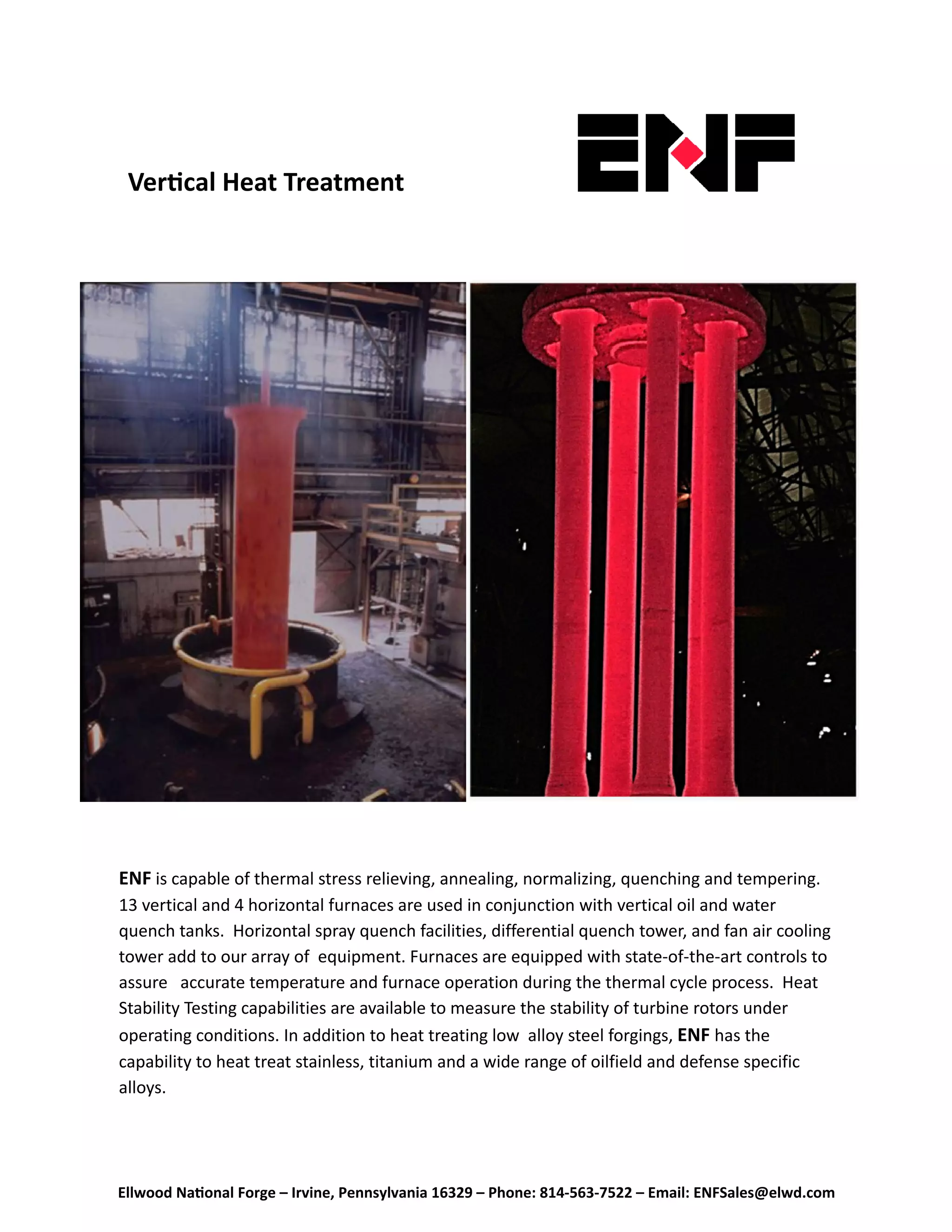

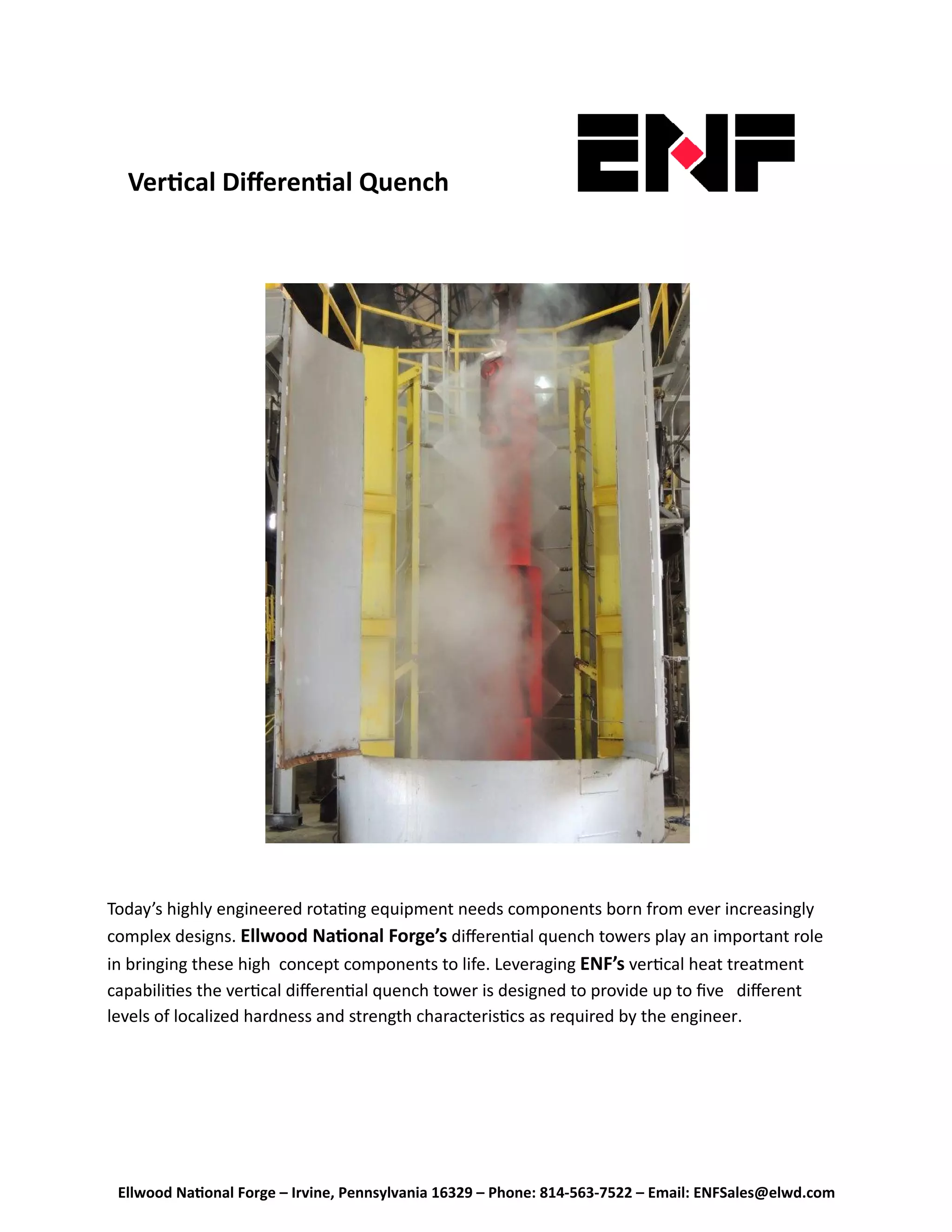

Ellwood National Forge (ENF) is a wholly owned subsidiary of Ellwood Group Inc. that offers turn-key manufacturing solutions by leveraging the parent company's vertical integration. ENF manages the entire production process from steel making to forging to finishing to deliver high quality parts on schedule. This eliminates multiple purchase orders and risks for customers compared to managing the process themselves.