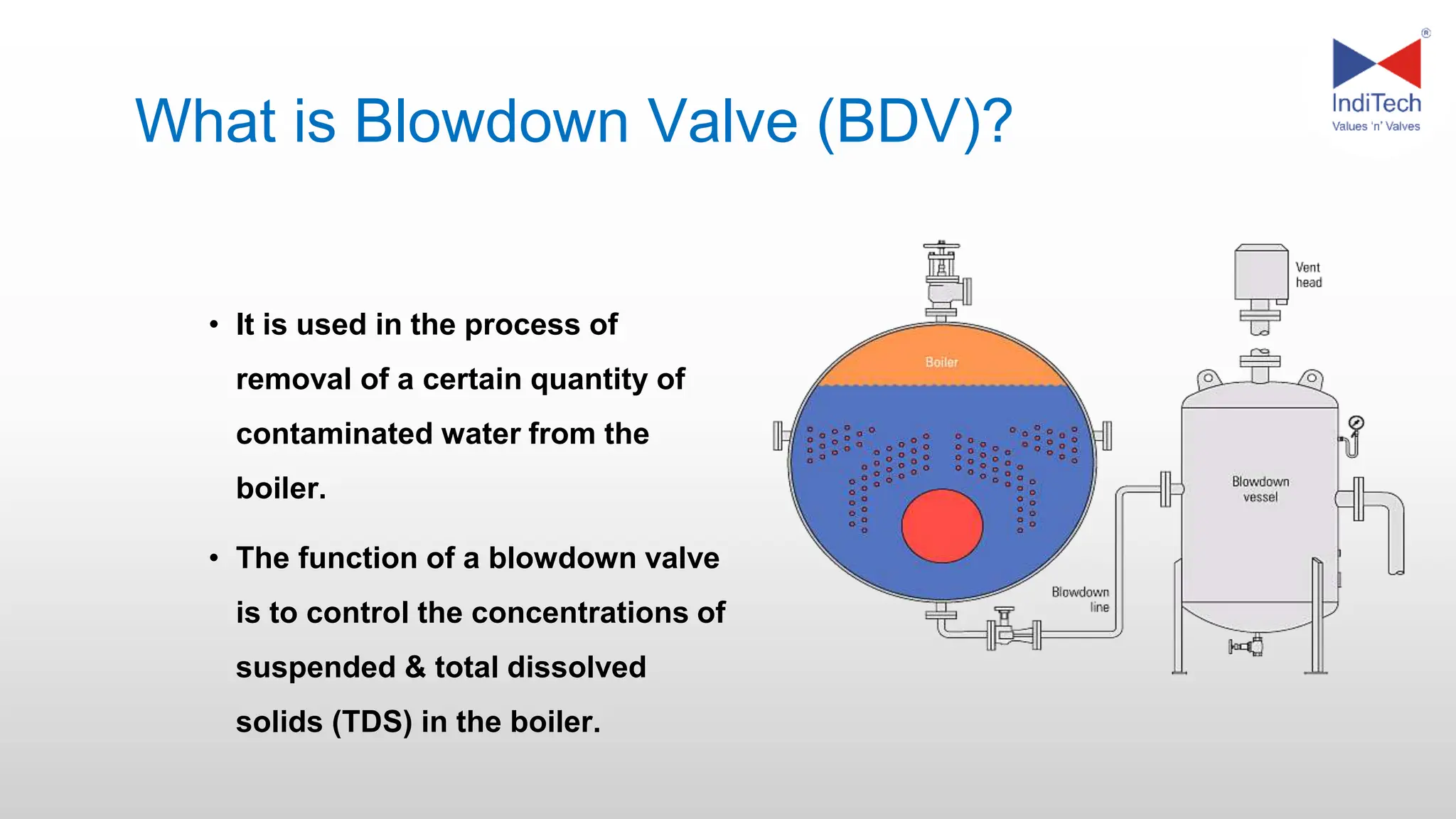

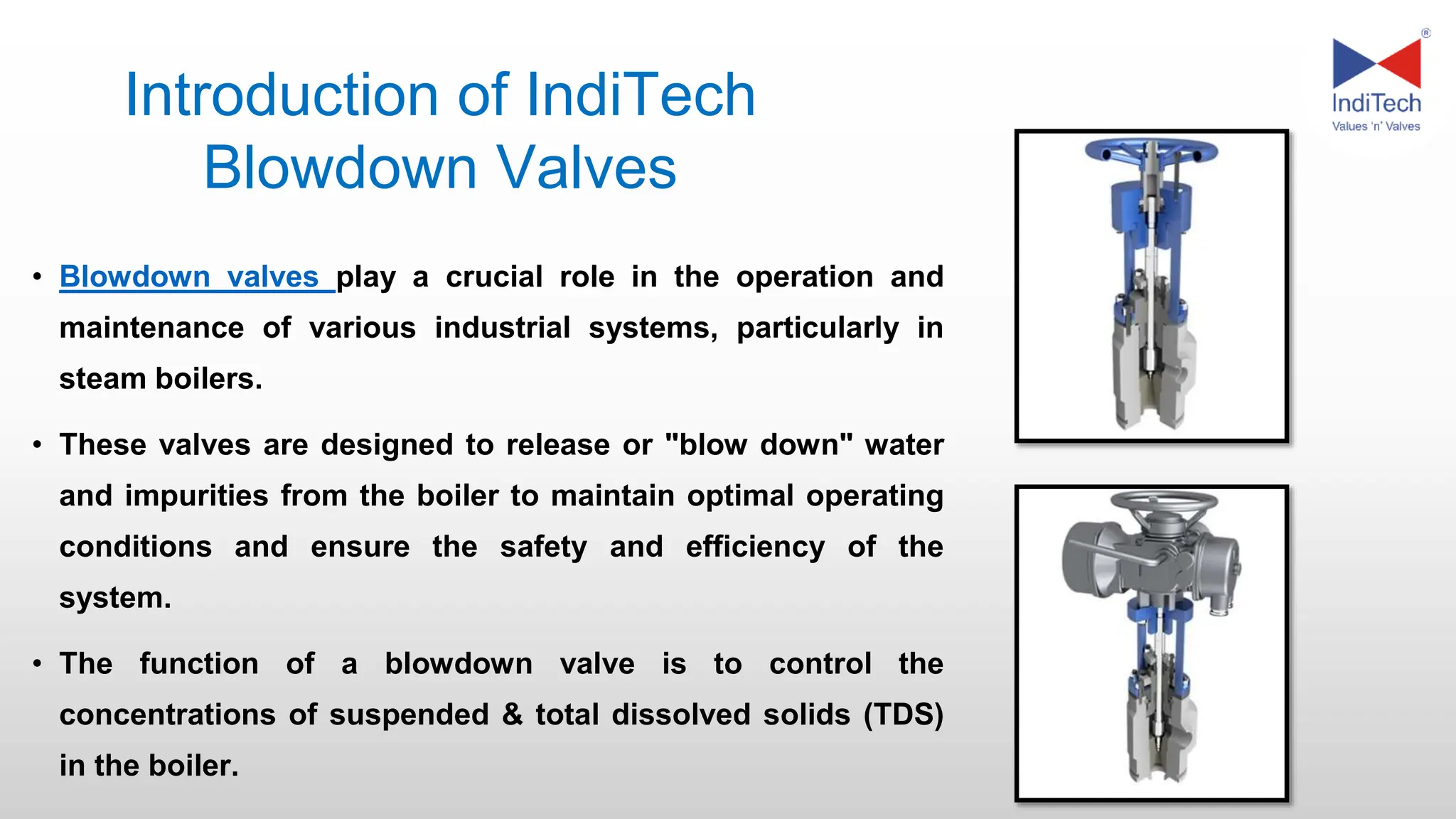

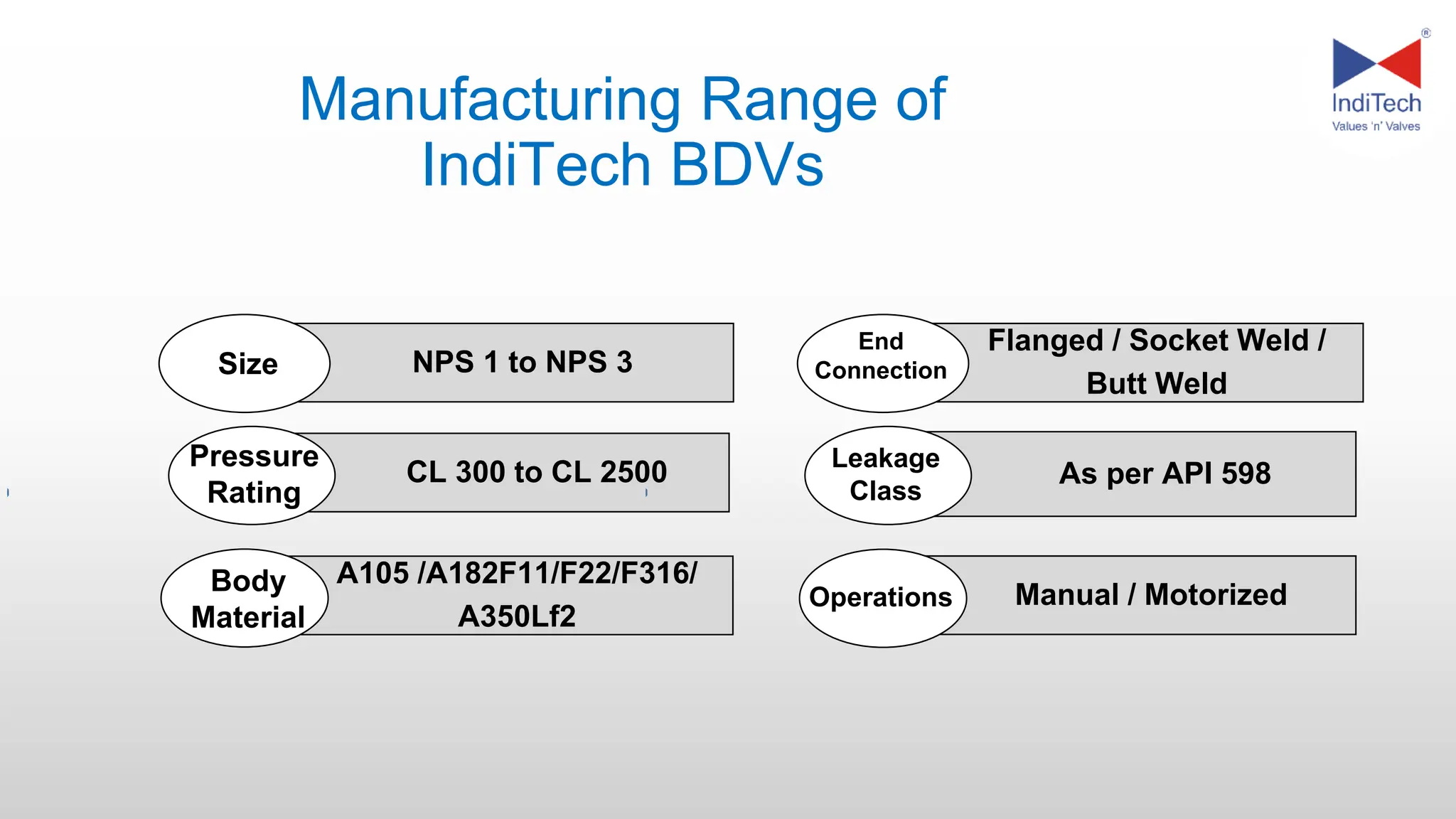

Inditech Valves Pvt. Ltd. specializes in blowdown valves (BDVs) used for removing contaminated water from boilers, helping to control dissolved solids and maintain operational efficiency. They offer two types of BDVs: Continuous Blowdown (CBD) for ongoing operation at the water level, and Intermittent Blowdown (IBD) for periodic operation at the bottom. Inditech's BDVs feature unique designs to enhance performance, durability, and leak tightness across various industrial applications.