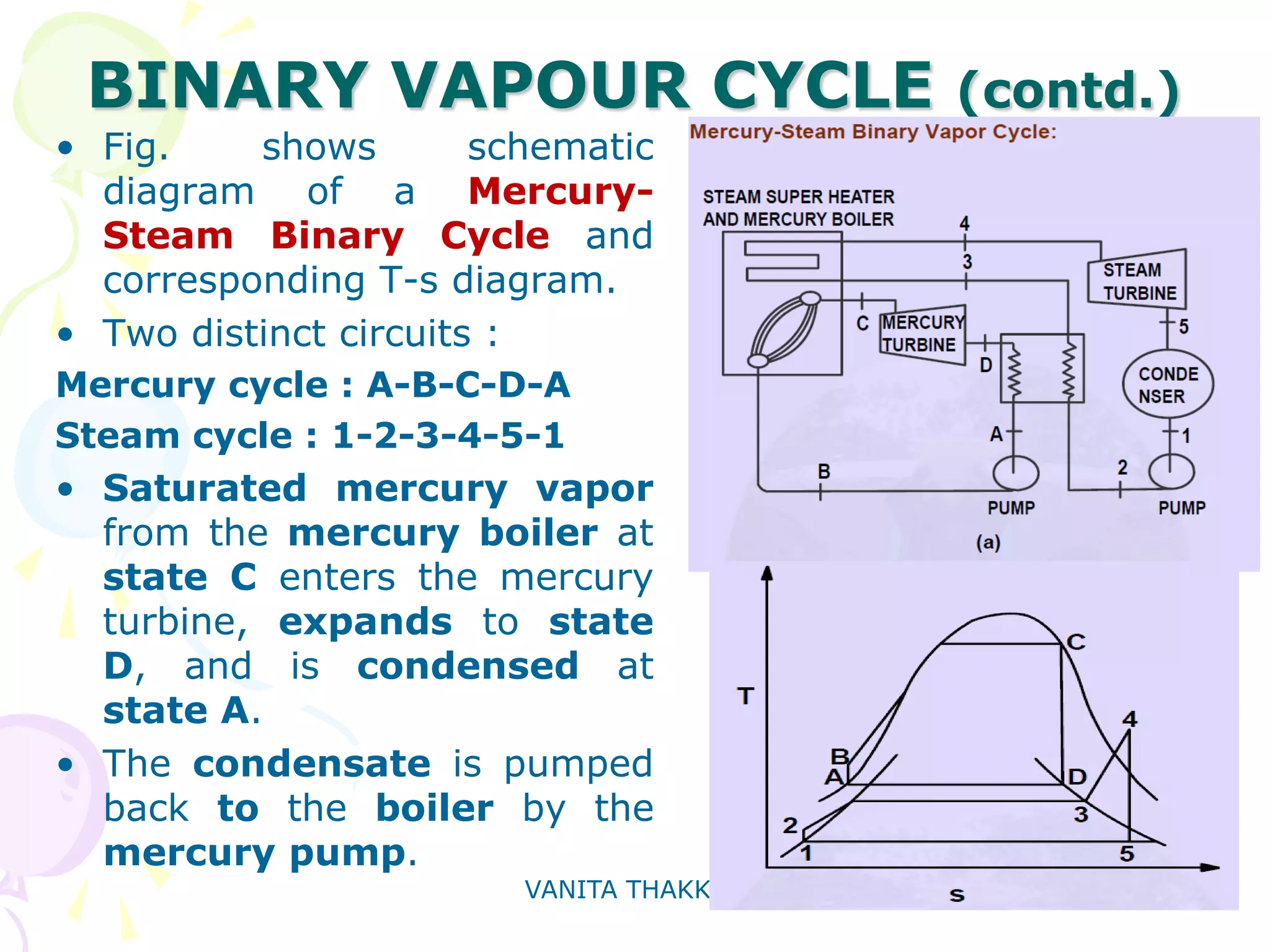

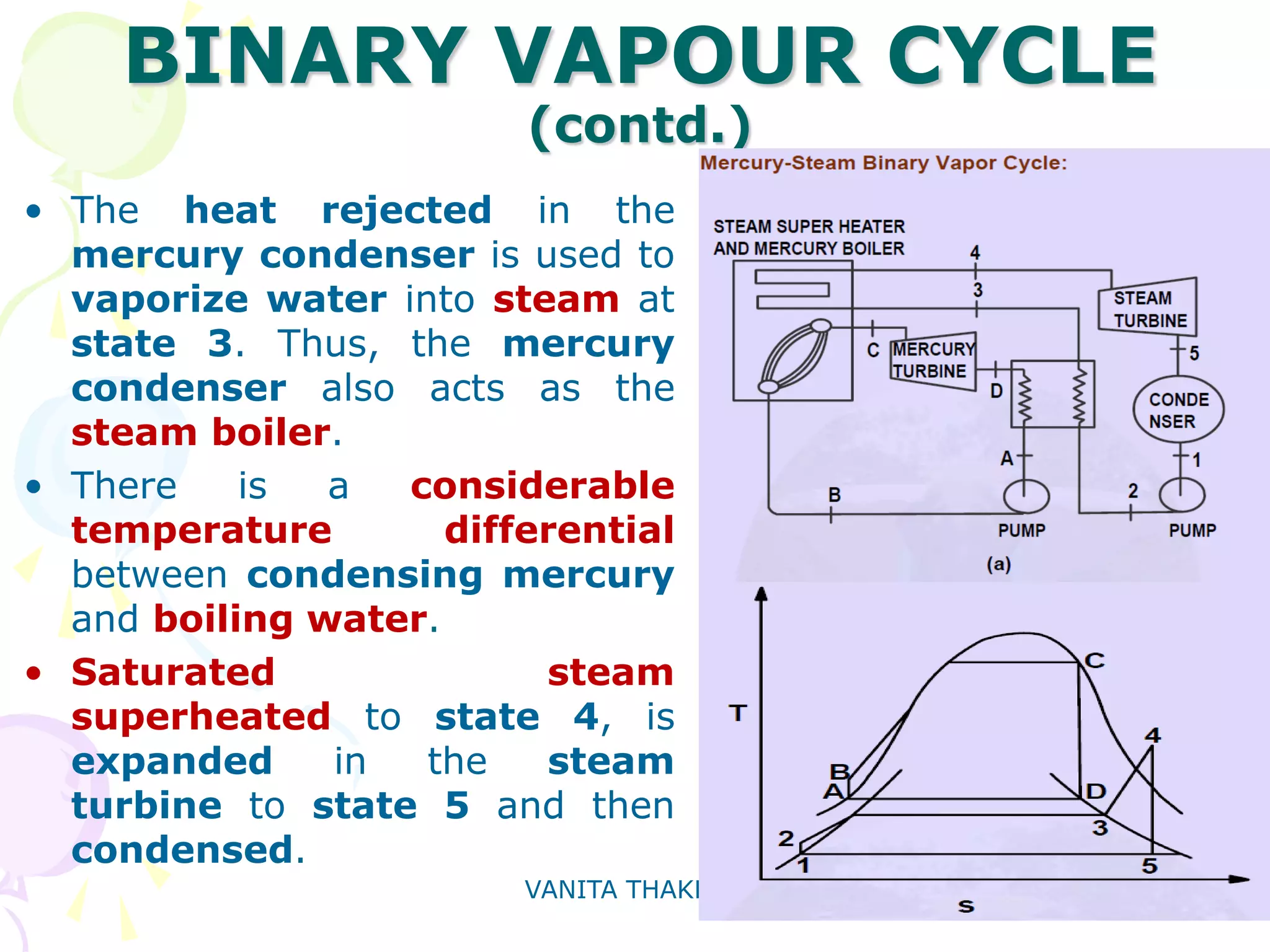

This document discusses various methods of improving the performance of steam turbines, including modifications to the Carnot and Rankine cycles. It describes the ideal Rankine cycle and limitations of using water as the working fluid. The use of superheated steam, reheat cycles, and regenerative feed heating are introduced to increase efficiency. Binary vapor cycles are proposed as an alternative working fluid to overcome some limitations of steam. Key concepts covered include Carnot, Rankine, reheat, regenerative feed heating cycles and the ideal properties desired in a working fluid.