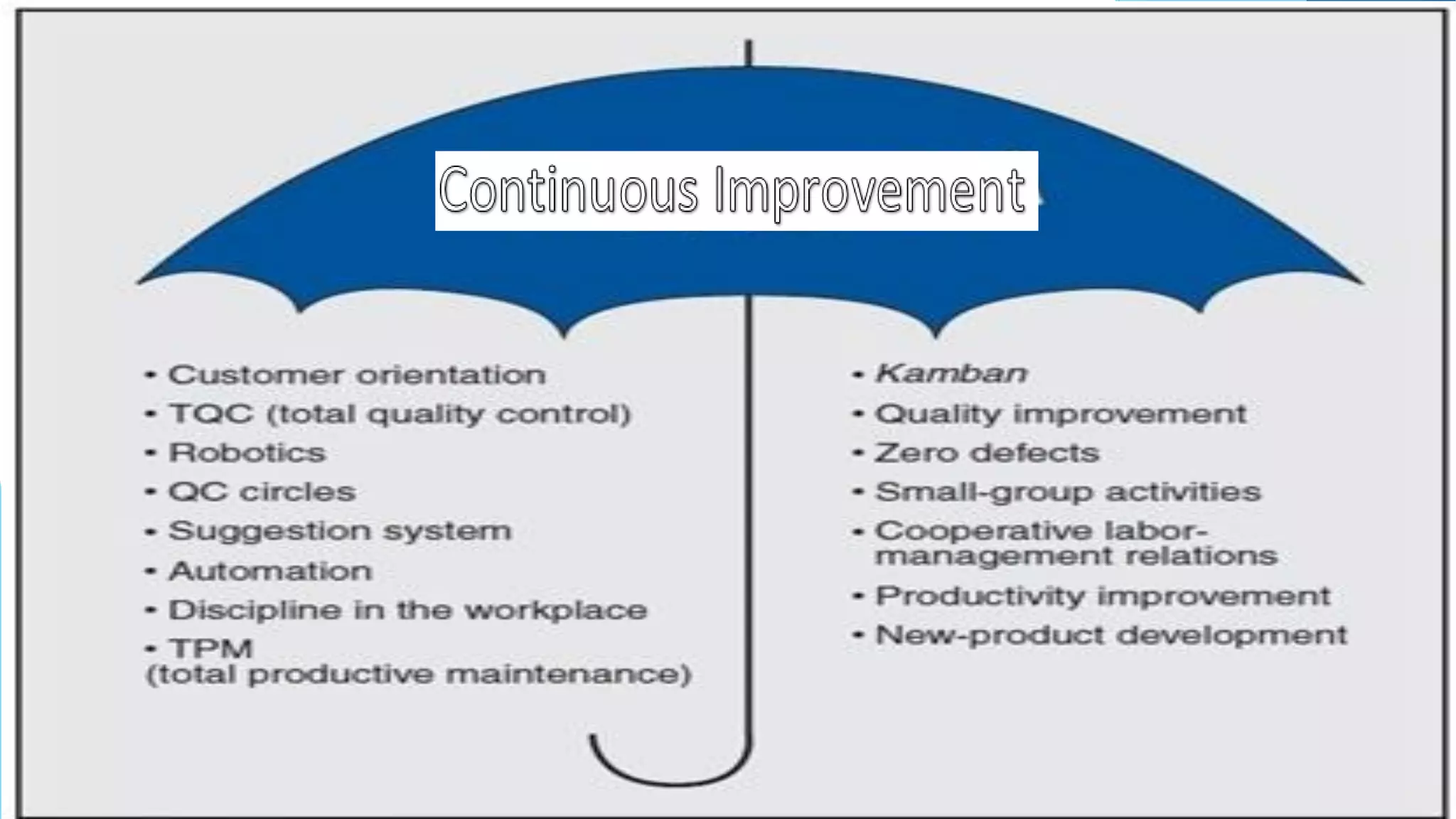

The document discusses continuous improvement as a systematic approach to enhance organizational efficiency by fostering a culture that eliminates waste and promotes employee innovation. It outlines various methodologies such as lean manufacturing and Six Sigma, highlighting their implementation processes and the challenges faced by organizations of different sizes. Case studies demonstrate the tangible and intangible benefits of continuous improvement, while also illustrating the common pitfalls and the importance of fitting the approach to the specific organizational culture.