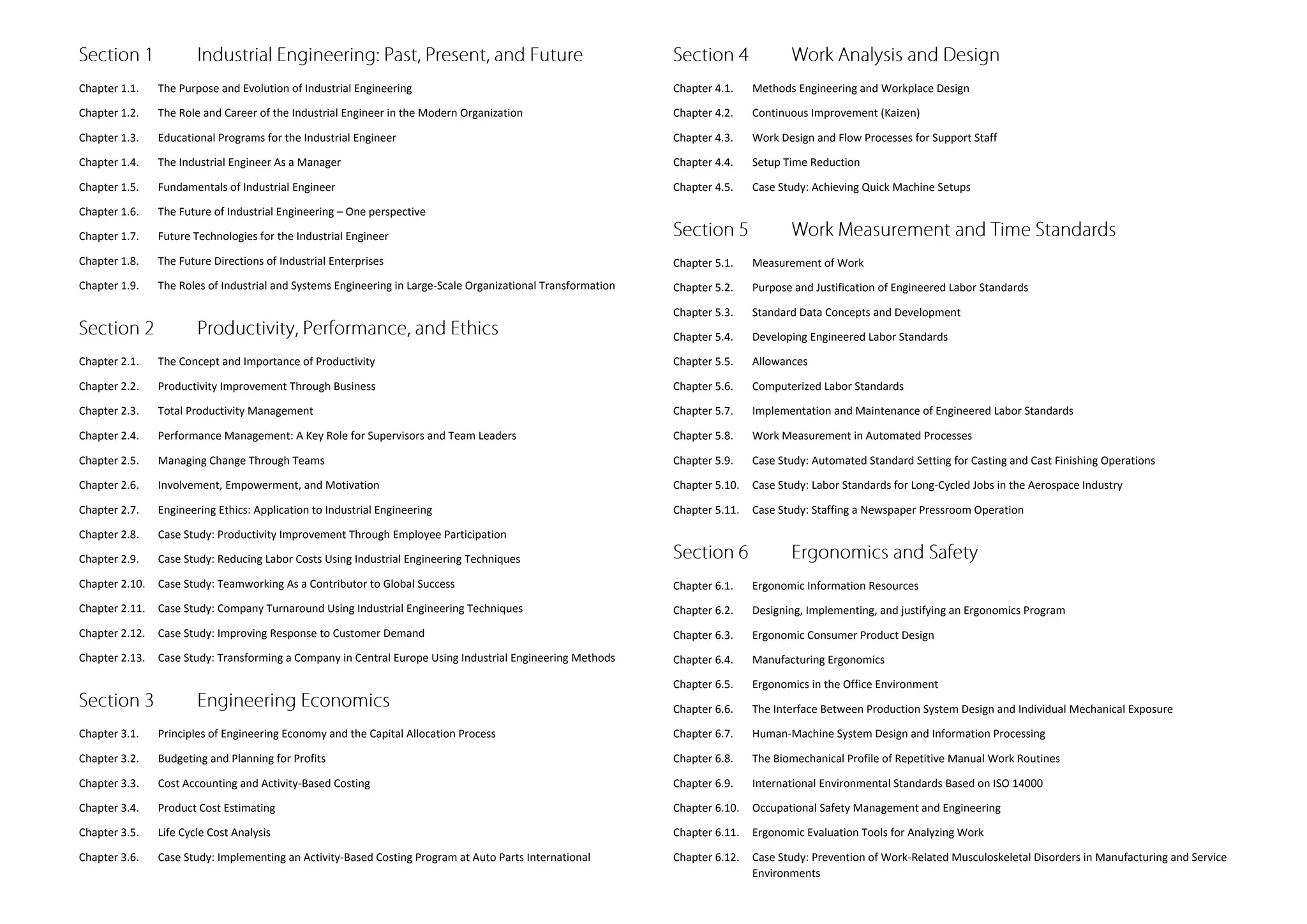

This document outlines 17 chapters that cover a wide range of topics in industrial engineering. The chapters discuss concepts related to productivity improvement, work measurement, facilities planning, manufacturing processes, quality management, maintenance, and other industrial engineering principles and applications. Case studies are also provided as examples of how industrial engineering techniques have been implemented in various industries. Overall, the document serves as a comprehensive overview of the field of industrial engineering.