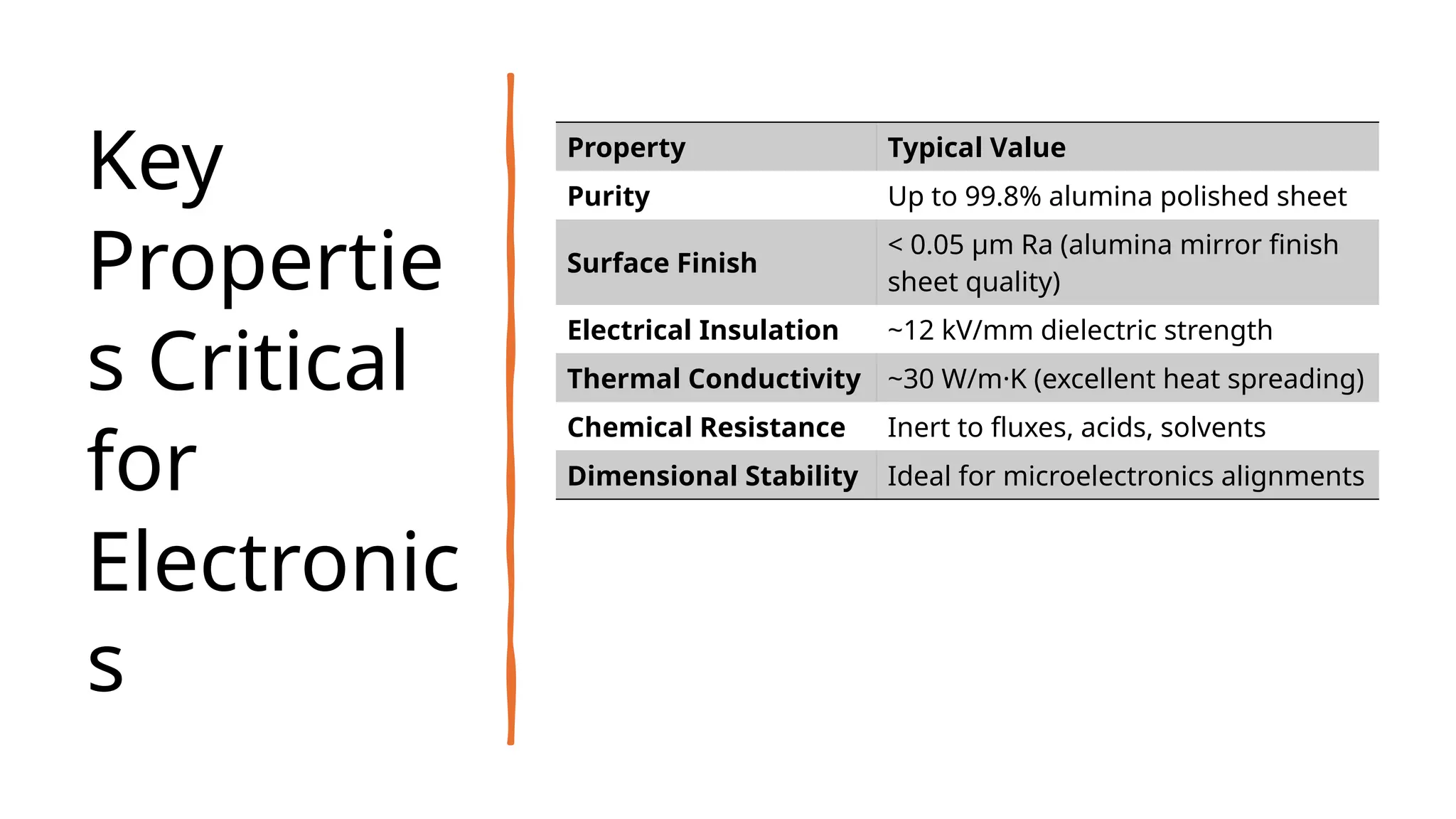

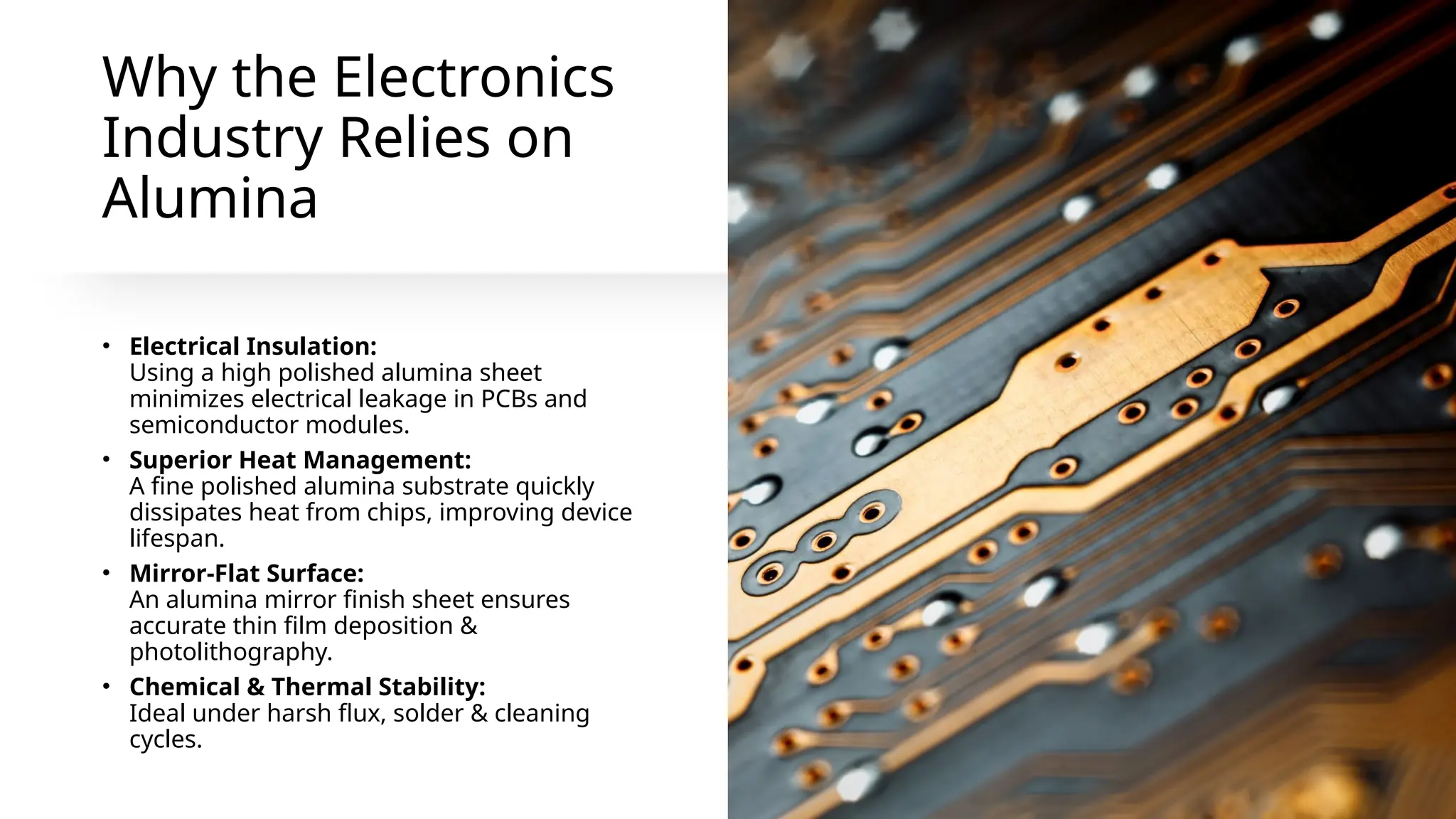

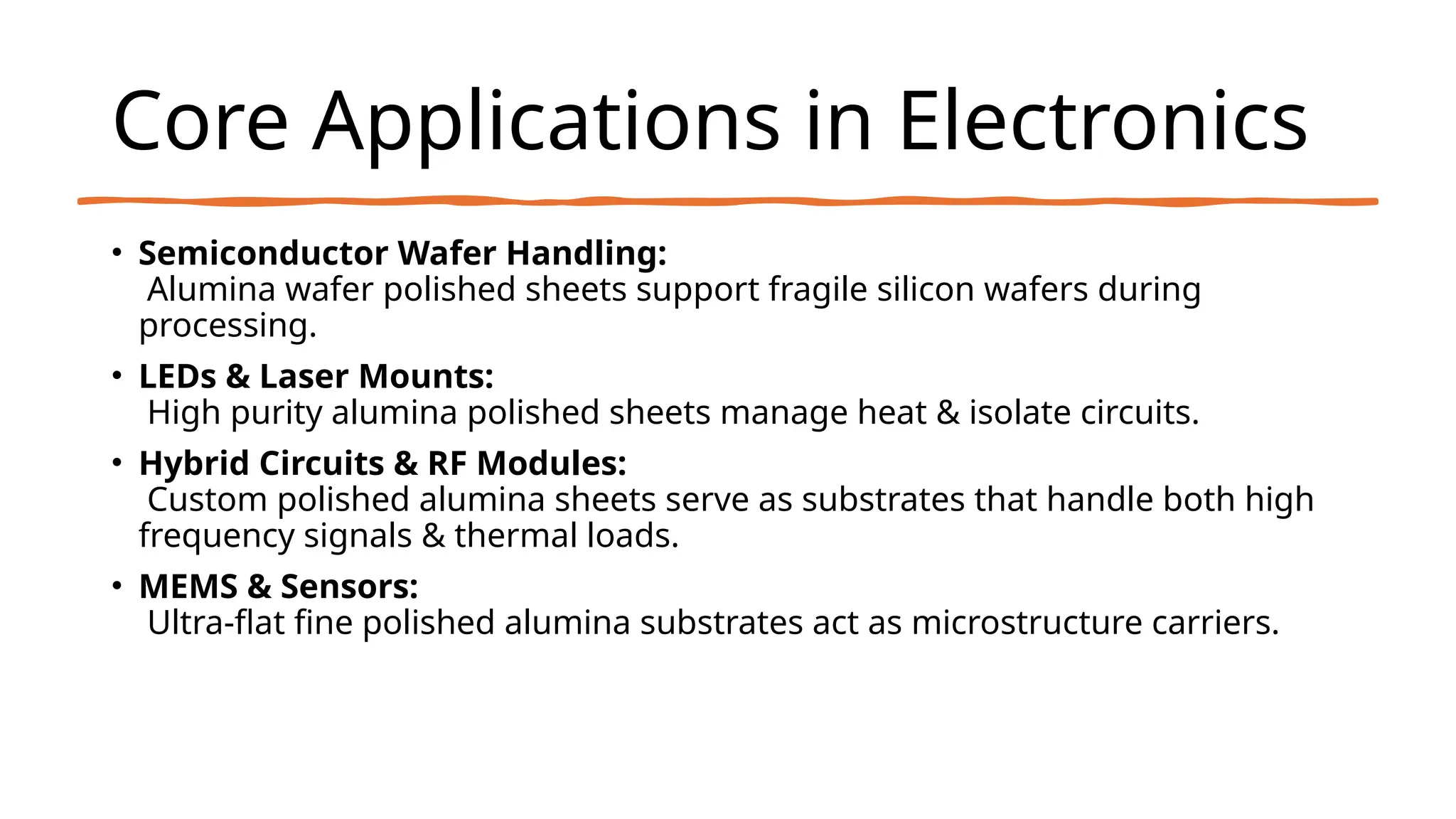

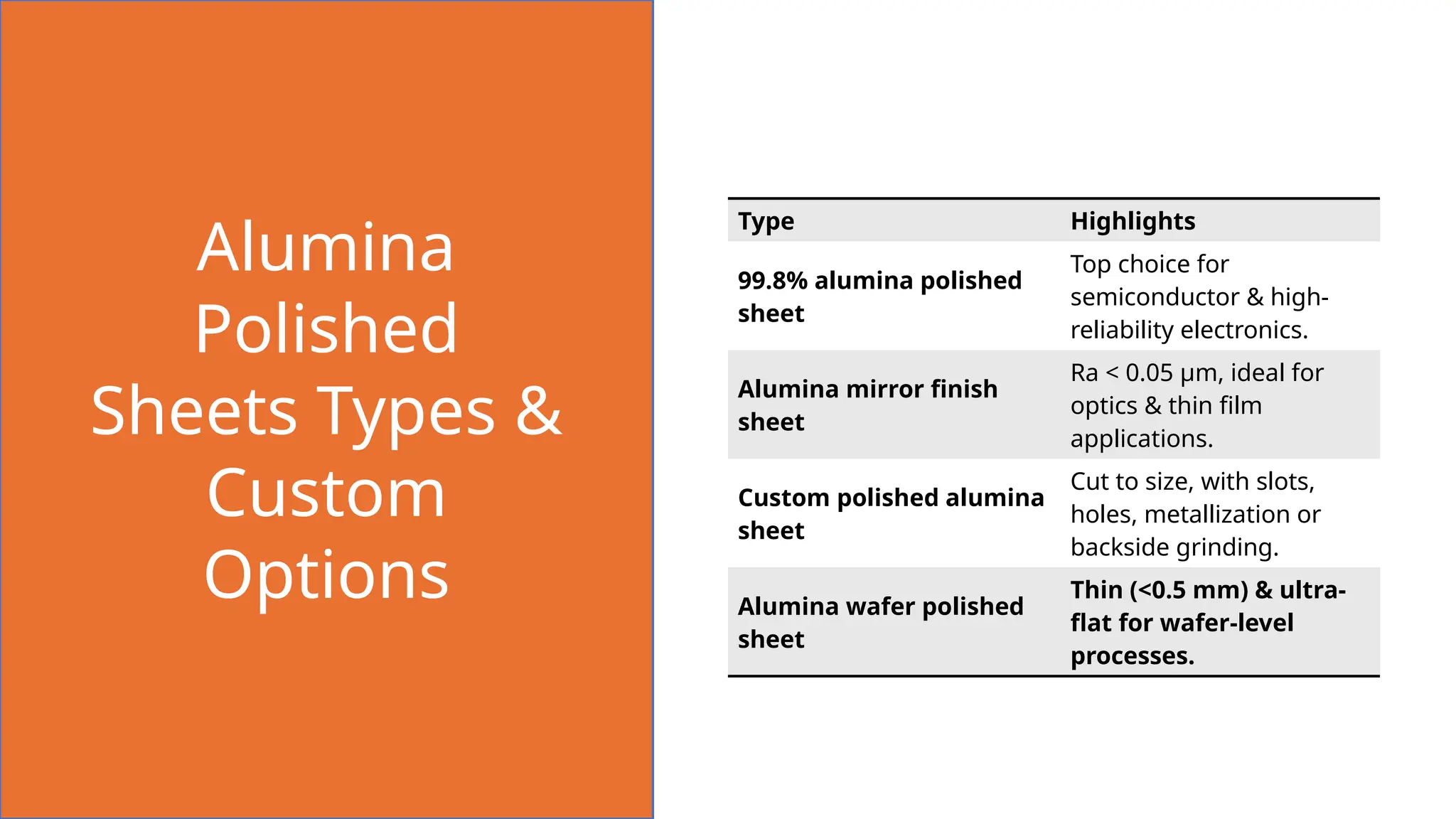

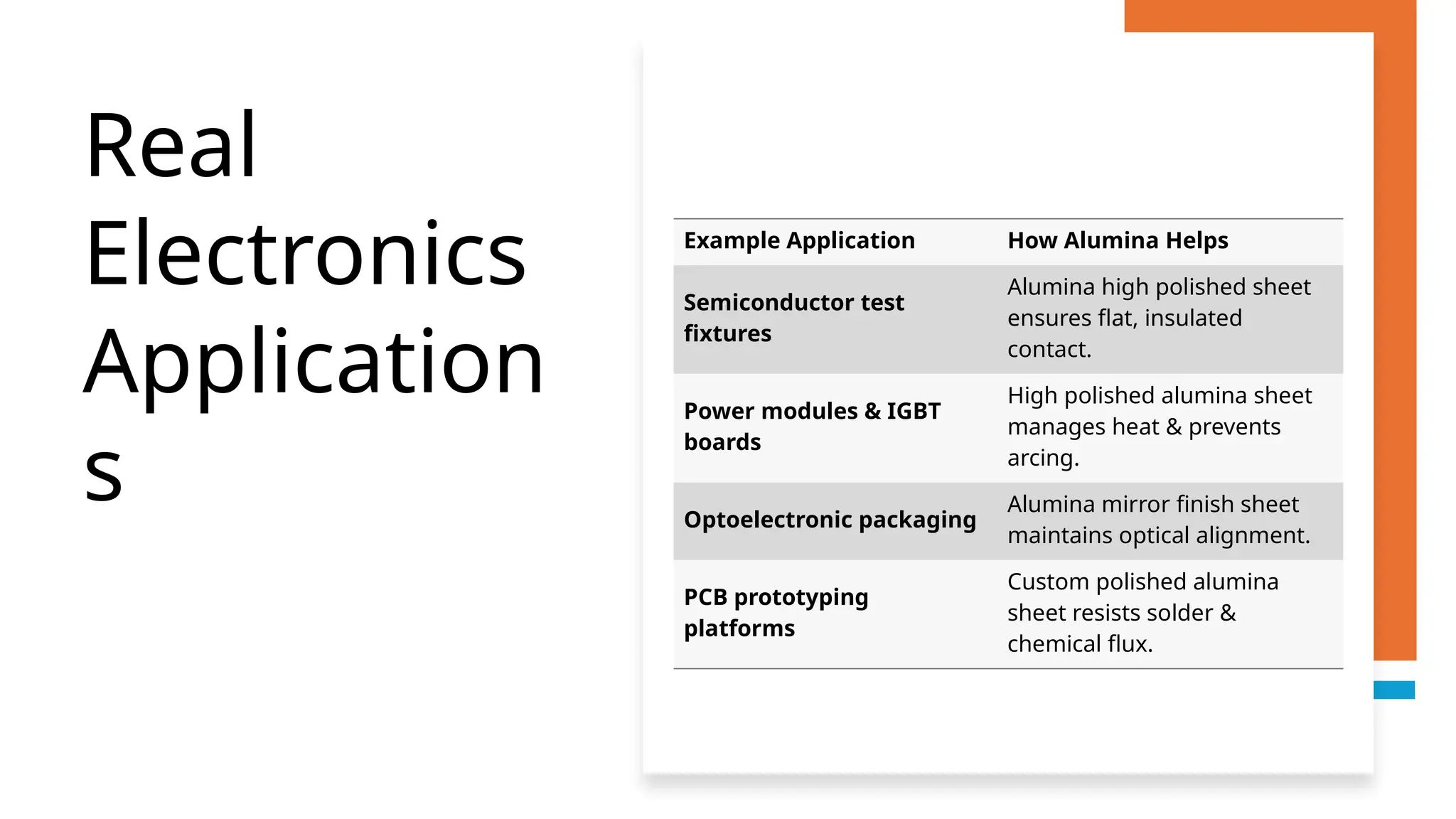

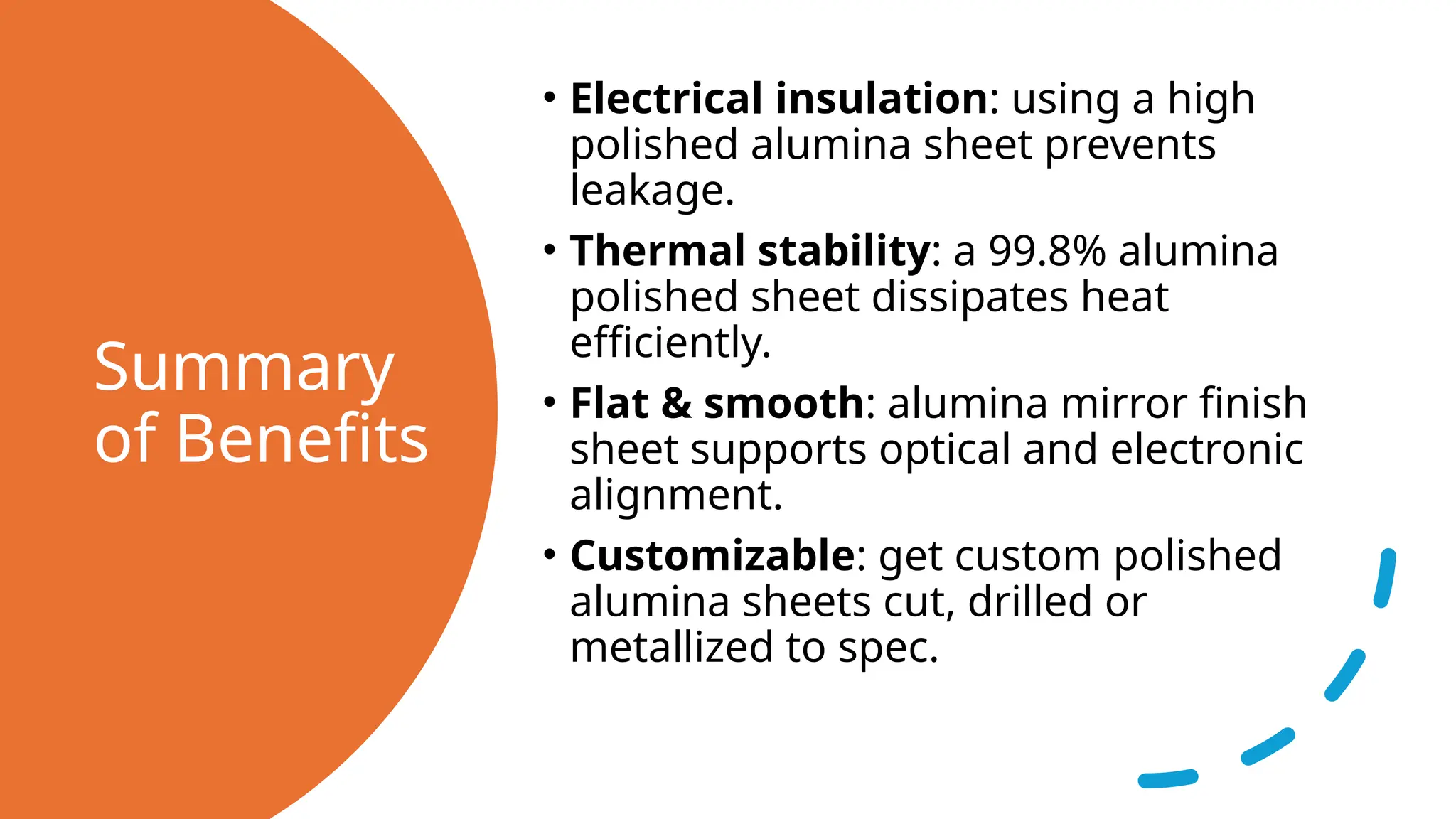

This presentation explains how the electronics industry benefits from alumina high polished sheets, highlighting their exceptional insulation, thermal stability, and smooth surface finish that support advanced semiconductor and microelectronic applications.