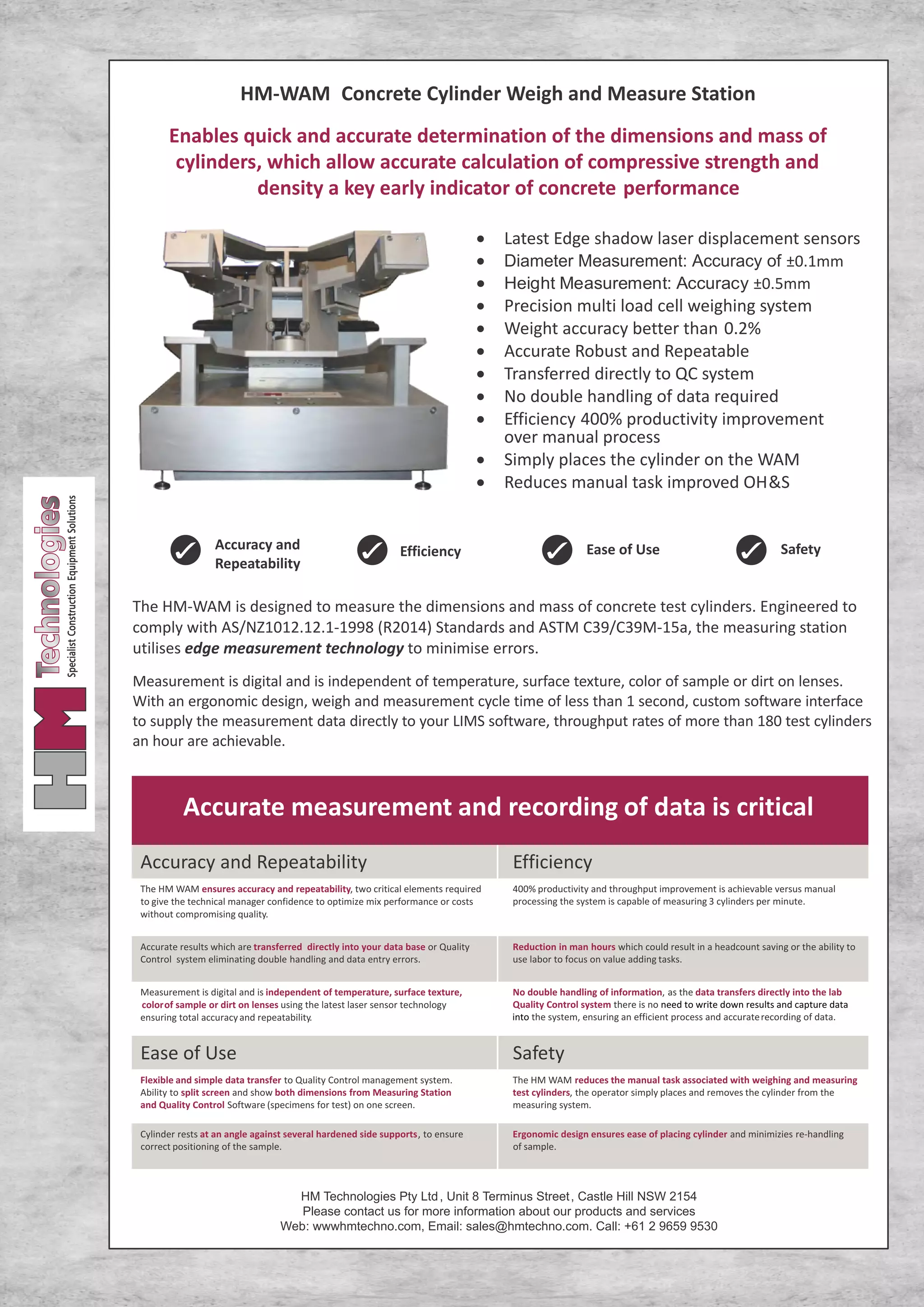

The HM-WAM is designed to quickly and accurately measure the dimensions and mass of concrete test cylinders to determine compressive strength and density. It uses latest laser sensor technology to measure diameter to ±0.1mm accuracy and height to ±0.5mm accuracy. The station transfers measurement data directly to quality control systems, eliminating double data handling, and can process up to 180 cylinders per hour, a 400% productivity increase over manual methods.